Explosion Screen Protective Film Cutter Mobile Cover Sheet

- Min. Order:

- 50 Piece/Pieces

- Min. Order:

- 50 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong, Shenzhen |

|---|---|

| Productivity: | 50000 pieces per day |

| Supply Ability: | 500000 pieces per week |

| Payment Type: | T/T,L/C,Western Union,Credit Card |

| Incoterm: | FOB,EXW,Express Delivery |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Hongkong |

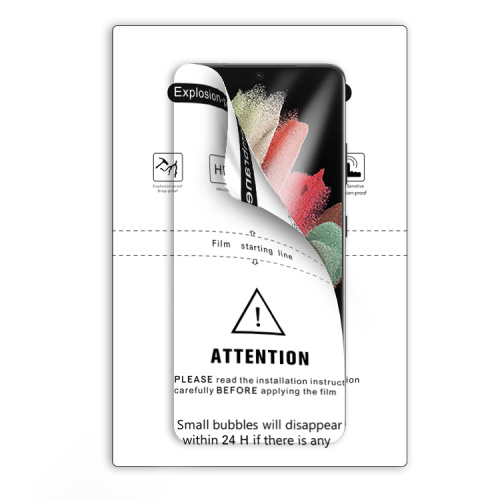

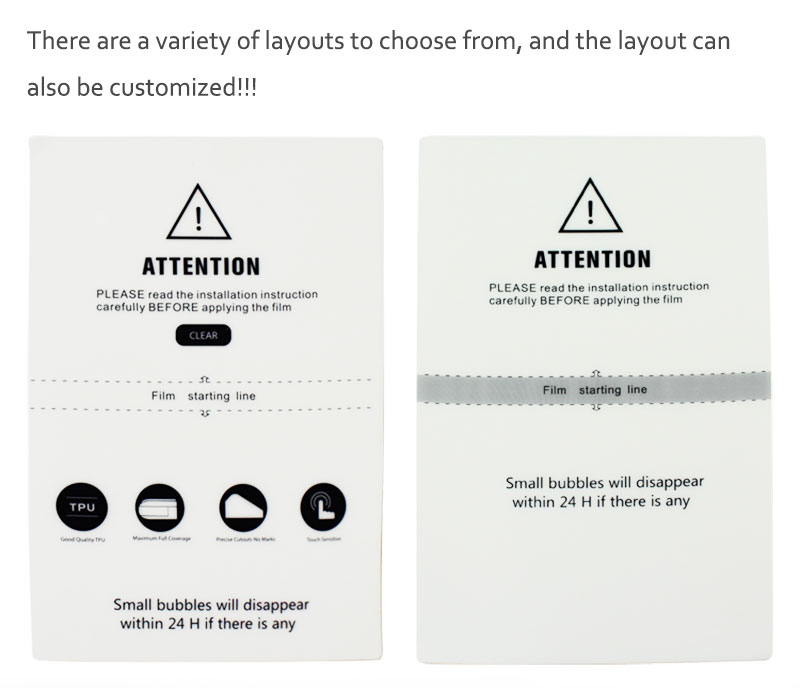

About The Hydrogel Screen Protector

The Hydrogel film is a honeycomb-structured TPU film, PVC film or PET film with super toughness. Plays a role in anti-falling, explosion-proof and a certain buffer against the collision of sharp materials. It is an innovative product.

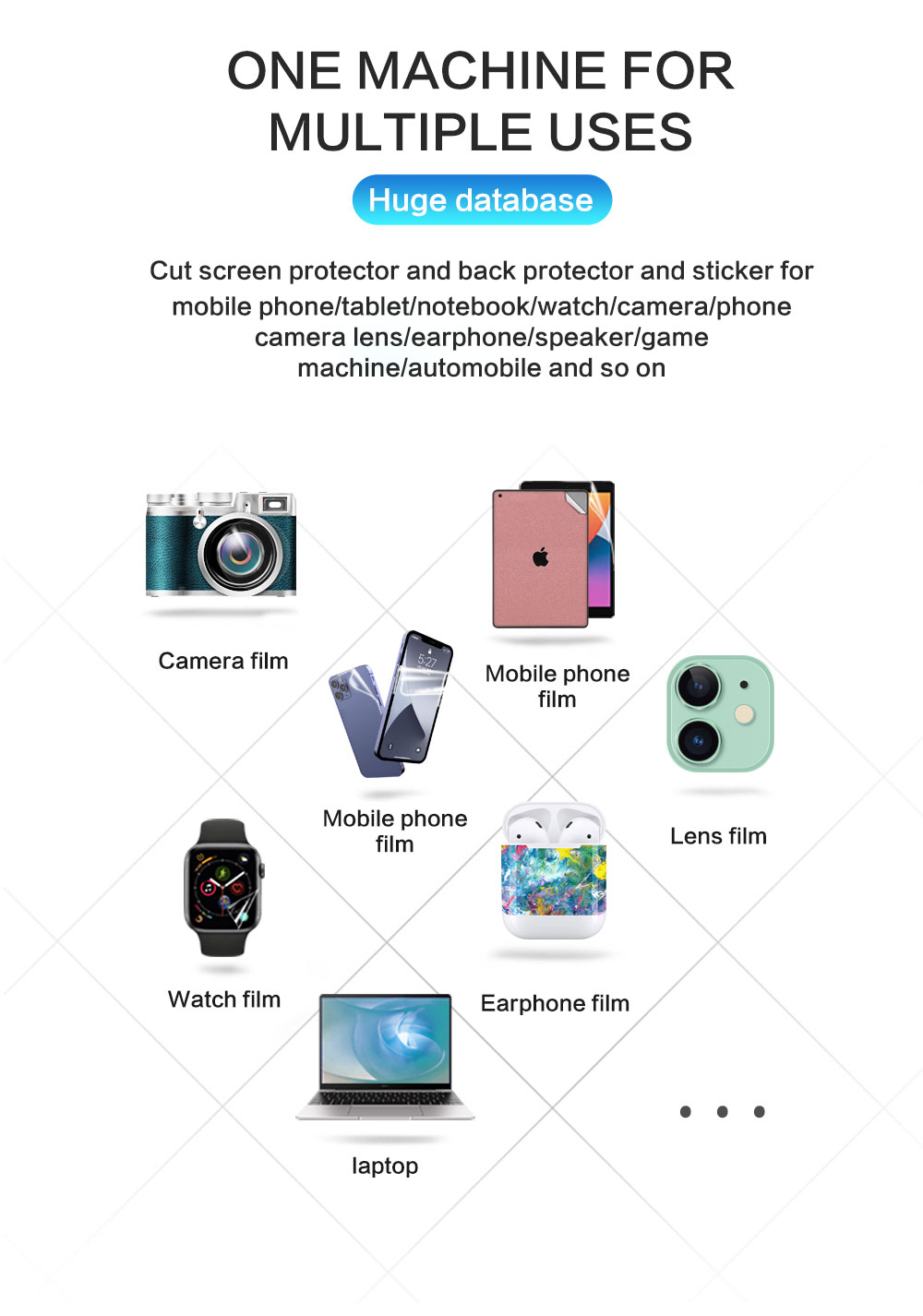

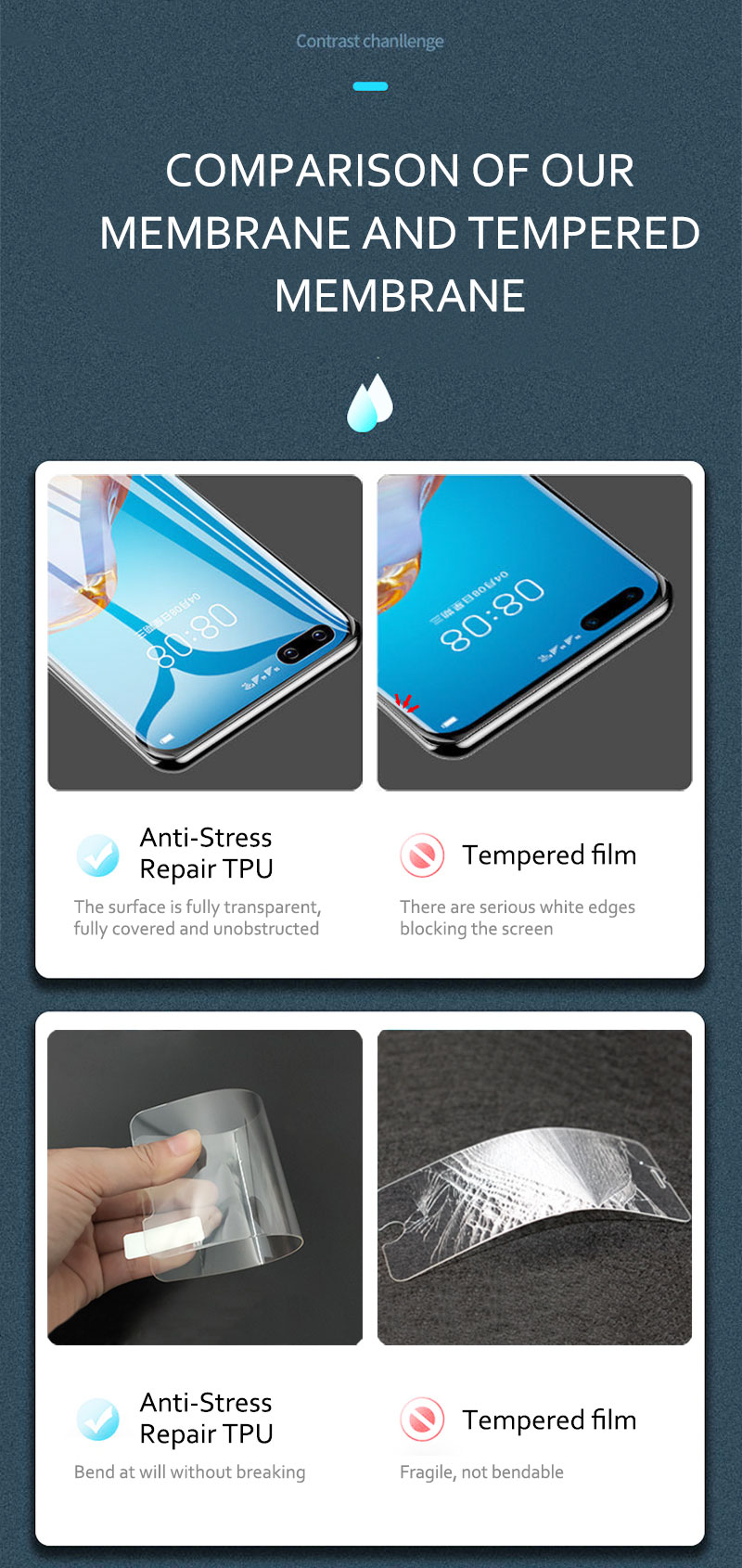

Thickness and Ease of Use Between the Liquid Screen Protector and Tempered Glass Screen Protector

Talking about the thickness or bulkiness, liquid screen protector is the winner. It goes almost invisible on your phone screen while its thickness is extremely thin. At the same time, it can well prevent scratches from happening to your smartphone over the everyday uses.

Tempered glass screen protectors are often thicker and a little bit bulkier. Thus, to users, they commonly prefer liquid screen protectors rather than tempered glass screen protectors. The only issue is it is riskier to apply.

What is the TPU hydrogel film?

The TPU hydrogel film is mainly made of super toughness TPU material with honeycomb structure, there are other materials such as PVC, PET, TPH. Compared with the traditional tempered glass film, the hydraulic film is softer, has super stretch and retractability, and is more friendly to the curved screen mobile phones on the market.

Hydrogel film is also very thin, the thinness is only 0.15mm thick, the light transmittance is more than 95%. Ultra-thin and invisible, truely display the original appearance of the cellphone!

High-tech waterproof technology added to dissolve any smudges, fingerprints or minor scratches. It can also automatically repair small scratches within 24 hours and repair air bubbles formed during the pasting process.

What is the difference between a die cutting machine and a laser cutting machine?

1. Die cutting machine

Advantages: fast cutting speed, low cost, suitable for simple protective film with low precision, blade cutting, smooth edges without burrs. No pollution and easy operation.

Disadvantage: Unable to cut harder films.

2. Laser cutting machine

Advantages: It can cut high-demand explosion-proof films, privacy films, hardened materials, etc., and has a good cutting effect on complex shapes such as small-angle holes. At the same time, the laser cutting machine does not need to make a knife mold, and can quickly make a good sample.

Disadvantages: high cost, one is about the price of three die-cutting machines. The cutting speed is slow, about five to six hundred slices per hour. Harmful gas and a lot of dense smoke will be generated during cutting, and the edges of cutting are prone to yellow edges and burrs.

Related Keywords