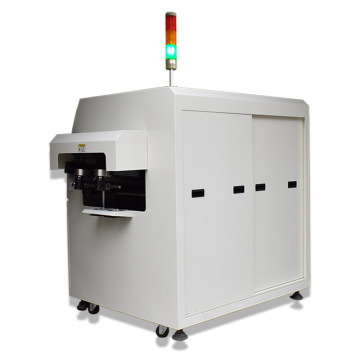

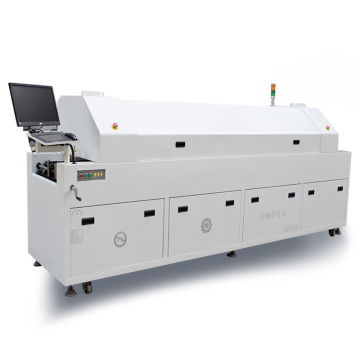

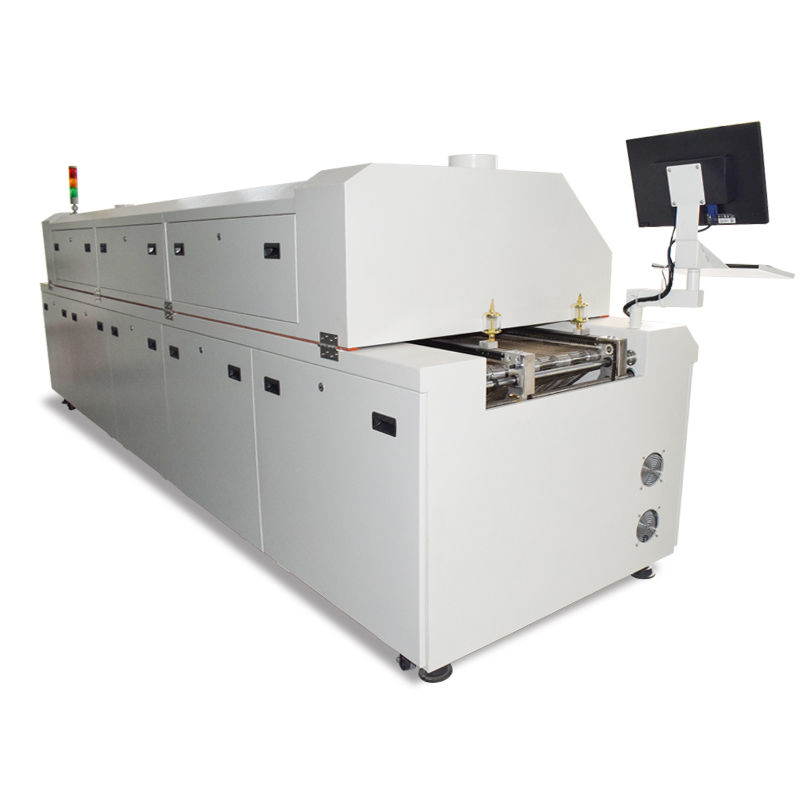

High-quality hot air reflow oven

- Transportation:

- Ocean

- Port:

- Yantian Port, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 300 units/year |

| Supply Ability: | Sufficient supply |

| HS Code: | 8515190010 |

| Transportation: | Ocean |

| Port: | Yantian Port, Shenzhen |

High-quality hot air reflow oven

Reflow soldering process

Printed board preparation-solder paste preparation-printing solder paste-mounting post-chip components-through reflow soldering-soldering completion-testing-shaping and trimming-completion

Features

·MAIJIE heating wire heating technology, independent wind structure, upper and lower heating methods, high thermal efficiency, rapid heating, about 20 minutes from room temperature to set working temperature, the difference between the set temperature of the welding zone and the actual temperature is less than 30 ℃.

·Using Taiwan Mitsukoshi special high temperature motor, direct drive hot air heating, hot air balance, low noise, low vibration, 0201 components can not shift during transportation.

·Unique air duct design, uniform air distribution, large heat capacity, preheating zone, constant temperature zone and welding zone heating up and down, independent circulation, independent temperature control, the temperature control accuracy of each temperature zone is ±1℃, the furnace opening adopts electric top cover type .

·Suitable for debugging the temperature curves of various models, with double or triple soldering zone settings, three-wire PROFILE TEST △ T as small as 8 ℃, and the connection curve test is especially compatible with Japanese or European and American standard lead-free soldering processes.

·Using a newly designed special transportation guide rail, made of high-temperature resistant, wear-resistant aluminum alloy, high rigidity and no deformation. The guide rail width adjustment system adopts a gear rack coaxial width adjustment device to ensure that the guide rail parallelism reaches ±5MM, which effectively prevents the occurrence of board jamming and board drop. And equipped with automatic and manual width adjustment device.

·The transportation system adopts Delta frequency converter stepless frequency conversion speed regulation, imported ZD motor drive, high-quality carbon steel chain and SUS316 stainless steel mesh belt for synchronous transportation, further ensuring smooth transportation. It is also equipped with UPS uninterruptible power supply and manual shake-out function, which can effectively prevent the PCB from being burned in the furnace due to sudden power failure.

·It has the function of timing automatic dripping and PCB counting.

·Adopt high-quality industrial computer control, LCD display, Windows XP operating system, flexible curve test and powerful dynamic curve analysis function, and all data can be printed and saved to meet the lead-free process.

·All electrical components are imported components, and all signal wires are shielded to ensure long-term stable and reliable operation of SMT 24 hours a day, and high-temperature components are free of charge for three years.

Installation and use conditions

<1>Working voltage: AC380V 50HZ three-phase five-wire system.

<2> Ambient temperature: 5~40℃;

<3>Relative humidity: not more than 85%RH;

<4>Power switch: air switch

<5> Installed power: 48KW

<6>The ground is flat, and there should be no strong vibration and corrosive gas in the surrounding environment.

Company strength

Workshop shots

Item display

About delivery

All the equipment of the company includes freight and distribution fees, excluding the cost of going upstairs, depending on the distance, choose logistics consignment or door-to-door delivery

On-site installation and commissioning

The company is responsible for distribution, and there are professional engineers on-site installation, commissioning, training, or guidance and assistance through remote video or telephone

1 year warranty

After-sales promises that all parts of the wave soldering machine are guaranteed for one year, except for human problems

Lifetime service

The company provides life-long maintenance, paid service, only labor costs and material costs

Preparation before installation and commissioning

1. Door-to-door time: within 2 working days after all the following work is ready, special circumstances will be discussed separately

2. Logistics transportation: After receiving the goods, customers who choose logistics transportation must first place the equipment and prepare all the following materials

3. Home delivery: Customers who choose home delivery need to reserve space in advance to prevent equipment and prepare all the following materials

Material preparation:

1. Power connection: lead the power cord to the device according to the requirements of the device, leaving a length of more than 3 meters to connect to the device

2. Air connection: If there is an air source in the workshop, lead the air pipe to the side of the equipment, leaving a length of more than 3 meters to connect to the equipment. If there is no air source in the workshop, you need to prepare the air compressor in advance and prepare the necessary accessories

3. Tin bar: Prepare enough tin bars in advance according to the tin capacity requirements of the equipment, so that the master can directly melt the tin for on-site trial welding test and training when he comes to the door.

4. Flux: the flux that needs to be used when the product is ready for trial welding. At least 2 liters required for testing

5. Cleaning agent: the nozzle used to clean the flux, temporarily not used, it will not affect the debugging

Related Keywords