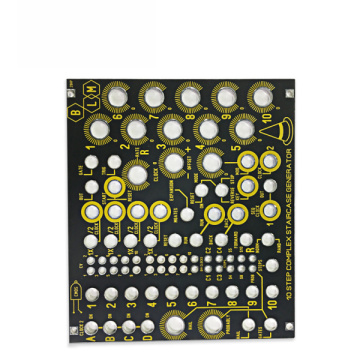

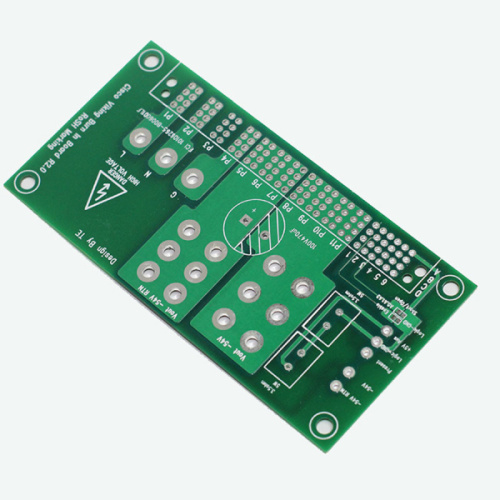

Double-sided PCB with 0.51mm Board Thickness

-

$1.02≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air, Land, Express, Others

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Paypal |

|---|---|

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Air,Land,Express,Others |

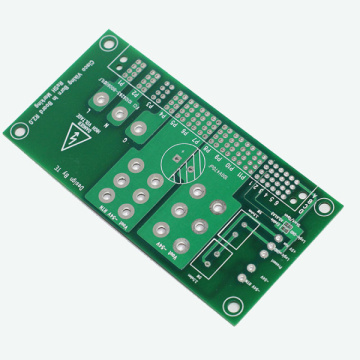

What is the difference between FR4 and FR5?

fr4 board, friends who first heard of this professional name may not have any impression of it. In fact, it is a grade number of flame-resistant material, which means that the resin material must be able to extinguish itself after being burned. It can be seen that the flame resistant performance of the product is relatively good. If there is an emergency fire or other problems, we do not have to worry about the spread of the fire. On the contrary, Flame resistant PCB can also effectively inhibit the loss of property and personnel. It is based on The color of the material can be classified, and it can also be classified according to the performance characteristics. You can refer to the following to understand the various information and performance of the fr4 board.

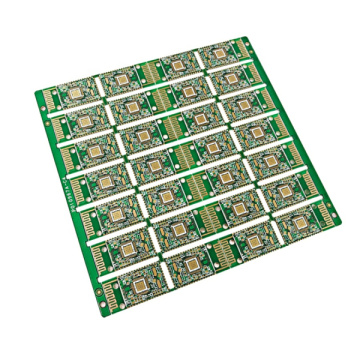

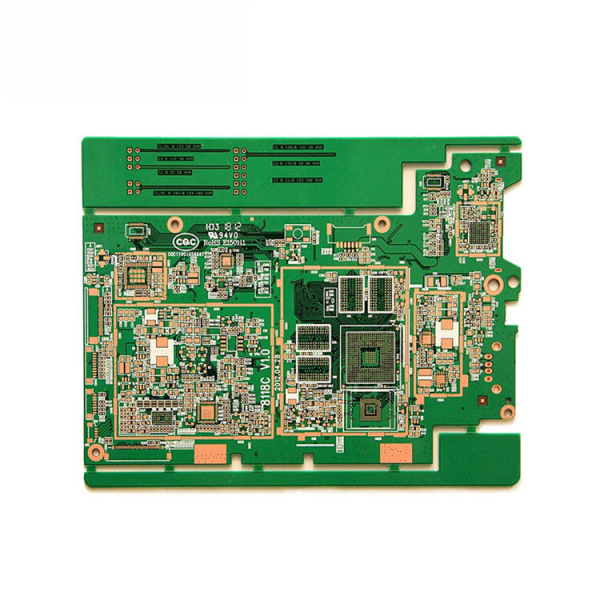

FR-4 is glass fiber epoxy copper clad laminate, a kind of substrate in circuit boards. In fact, you should have seen it. For example, when the small game console is taken apart, the green board inside is made by FR-4. circuit board.

FR4 and FR5 epoxy boards are laminated products made of special electronic cloth impregnated with epoxy phenolic resin and hot pressed at high temperature and high pressure. It has high mechanical properties and dielectric properties, good insulation properties, heat resistance and moisture resistance, as well as good machinability. Application: used as insulating structural parts in motors and electrical equipment, and also widely used For PCB testing; and can be used in humid environment conditions and transformer oil.

FR-4 is the code name of a flame-resistant material grade. It represents a material specification that the resin material must be able to extinguish by itself after burning. It is not a material name, but a material grade. Therefore, the current general circuit There are many types of FR-4 grade materials used in the board, but most of them are composite materials made of so-called Tera-Function epoxy resin, Filler and glass fiber.

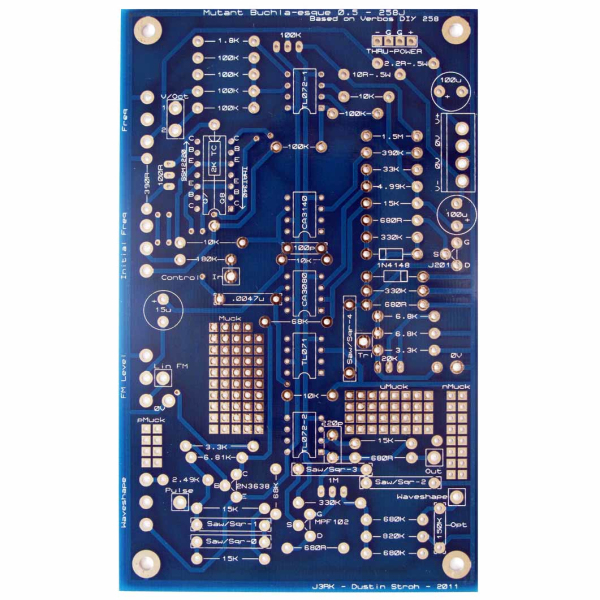

FR-4 epoxy glass cloth laminate, according to different uses, the industry is generally called: FR-4 Epoxy Glass Cloth, insulating board, epoxy board, epoxy resin board, brominated epoxy resin board, FR-4 , Fiberglass board, fiberglass board, FR-4 reinforcement board, FPC reinforcement board, flexible circuit board reinforcement board, FR-4 epoxy resin board, flame-retardant insulation board, FR-4 laminated board, epoxy board , FR-4 light board, FR-4 fiberglass board, epoxy glass cloth board, epoxy glass cloth laminate, circuit board drilling pad.

Main technical features and applications: electrical insulation, stability, good flatness, smooth surface, no pits, thickness tolerance standard, suitable for products with high-performance electronic insulation requirements, such as FPC reinforcement boards, PCB drilling pads , Glass fiber meson, potentiometer carbon film printed glass fiber board, precision star gear (wafer grinding), precision test plate, electrical (electrical) equipment insulation support spacer, insulation backing plate, transformer insulation plate, motor insulation, grinding Gears, electronic switch insulation boards, etc.

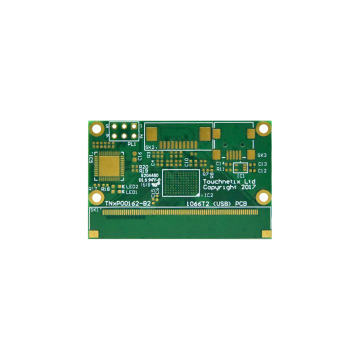

FR-5 has better advantages over FR-4:

1, TG, TD are higher;

2, better heat resistance, about twice that of ordinary FR-4;

3, Z-CTE is smaller, suitable for high multi-layer boards;

4, T288 is better.

FR4 and FR5 epoxy plates are laminated products (such as high frequency mixing pressure plate) made of special electronic cloth impregnated with epoxy phenolic resin and hot pressed at high temperature and high pressure. It has high mechanical properties and dielectric properties, good insulation properties, heat resistance and moisture resistance, as well as good machinability. Application: used as insulating structural parts in motors and electrical equipment, and also widely used For PCB testing; and can be used in humid environmental conditions and transformer oil.

Related Keywords