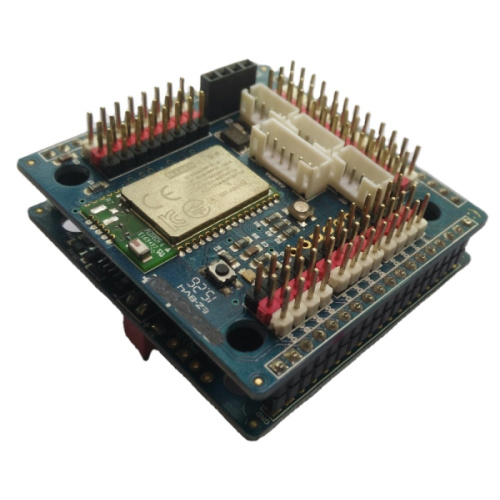

Control Board PCBA, PCB Assembly with BGA

-

$12.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is PCB board assembly?

Circuit board components participate in various steps. This is a non-linear process, indicating that factors need to be considered, and the process can be changed and adjusted based on these factors. The expected result and the use of PCBA are one of the main considerations in determining components and the general PCB assembly process.

The following are some parts and components PCB component that need to be carried out:

1. Basic printed circuit board or substrate

2. Electronic Components to be installed on the circuit board. This depends on the use of the circuit board and the complexity of the equipment. For example, PCBA for radios is relatively simpler than PCBA for computers. In fact, some computers can have up to 12 different circuit layers on the PCB.

3. Soldering materials, solder wire, solder paste, preforms and other welding materials. The preform depends on the type of welding to be carried out.

4. Flux

5. Other welding equipment such as soldering station, wave soldering machine, inspection, test equipment and SMT equipment. The use of equipment depends on the expected results, cost and time resources. For example, the reflow soldering process used in electronics is mainly gas phase and infrared. Based on the above factors, choose one of the processes.

When all the necessary components are ready, you can start the quick turn pcb assembly process. But before we get into the assembly process (it is a different type), let us know more about the circuit board itself.

Surface-Mount (SMT) &BGA Assembly

Surface mount components (or surface mount technology, also known as SMT) is a method in which electronic components standing upright on the PCB are directly connected to the surface of the circuit board. The final circuit board is called a surface mount device (SMD). This technology was originally called "flat mounting".

Through-Hole Assembly

Through-hole technology (also called "through-hole") is a mounting technology in which electronic components are inserted through holes built into the circuit board and then soldered to the pads. Welding can be done manually or using a plug-in installation machine.

Through hole technology replaces the traditional point-to-point structure. As double-sided and multi-layer boards become more and more popular, through holes are becoming popular. It is used to connect the component and the conductive layer to ensure the normal operation of the circuit board. These components are equipped with leads to connect to the other side of the through-hole board.

In contrast to the SMT method, the through-hole technology provides greater cohesion for the circuit board assembly because the unit is placed through the circuit board itself.

Electro-Mechanical components use electrical and mechanical units to cover a wide range of functions such as generating electricity, controlling switches and other mechanical tasks. Since electromechanical components are often used in applications with complex wiring and components, the components need to be put together manually.

Therefore, it can usually be time-time consuming. However, major manufacturers like RayPCB like us, use this technology and break down the process into individual market segments and use experts in each segment. Therefore, we can shorten the lead time.

Common uses of each type of PCB assembly

Surface mount technology is most commonly used in personal computers and is still in use. It is one of the most widely used technologies in the electronics field and is widely used in consumer electronic products, including smart phones, computers, TVs, microwave ovens, etc. But before SMT was introduced, it was a through-hole technology that dominated the personal computer market.

In fact, IBM was the pioneer of this process and pushed it to the mainstream. At present, through-hole technology is more used for larger components, such as Electronic Resistor and Capacitor, because it can hold components better than SMT.

Electromechanical components are due to their versatility in power-enhancing mechanical functions, and are usually used for AC and DC power distribution, computer interfaces and control systems.

in conclusion

PCB is a very close and dear part of our contemporary life, although we still haven't noticed it. Over the past few decades, the technology for effectively assembling and installing components has rapidly developed into a quick-to-point structure from through-hole to SMT. In addition, each has its own advantages and disadvantages, making them very suitable for certain tasks rather than others.

Related Keywords