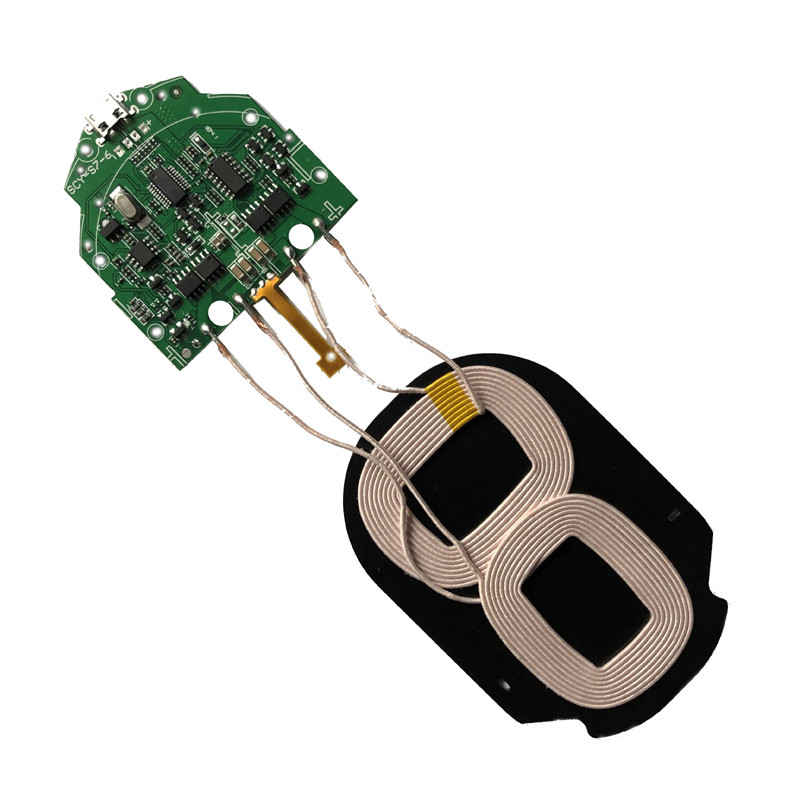

wireless charger PCBA for electronic productions

-

$10.00≥3 Piece/Pieces

- Min. Order:

- 3 Piece/Pieces

- Min. Order:

- 3 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now

How to judge the quality of solder joints on CBA board?

Pcba boards are generally inspected in SMT factories in accordance with ipC-A-610 standards. Since there are many types of solder joints, it is difficult to describe them simply. Therefore, we decompose solder joints into multiple dimensions and evaluate them with a single requirement. It's a way of dealing with complex problems, and it's worth learning.

1. Figure 1-8 shows the qualification requirements for solder joints of inserted components in Smt processing. The pin trace of the plug-in should be obvious and can be identified. This is an important sign to judge whether the short pin is welded falsely. If the spherical appearance is formed, it is generally welded falsely, so that the quality of the solder joint can be judged.High Quality Prototype PCB Fabrication

2. The qualified requirements of solder joints at the bottom welding end in Smt patch processing are shown in Figure 2. cheap custom pcb fabrication At the bottom welding end, custom pcb fabrication Quick-turn PCB fabrication want to control the quality of the solder joint. First, we do not allow the welding end to stretch out. The width of the solder joint is greater than or equal to 50%.

Qualified solder joint quality usually has the following points:

1. Spread symmetrically into skirt shape with welding wire as center.PCBA Online Quote

2. Solder joints, solder joints are concave and natural transition, solder and solder junction smooth, contact Angle as small as possible.

3. The surface is smooth and has a metallic luster.

4. No crack, pinhole, slag inclusion.

5. No defect welding, wrong welding, leakage welding and other phenomena.

Related Keywords