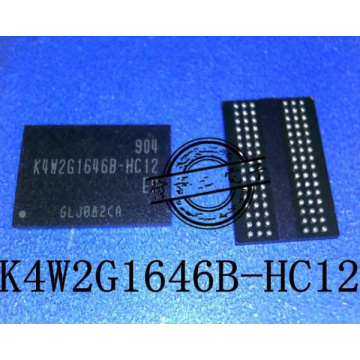

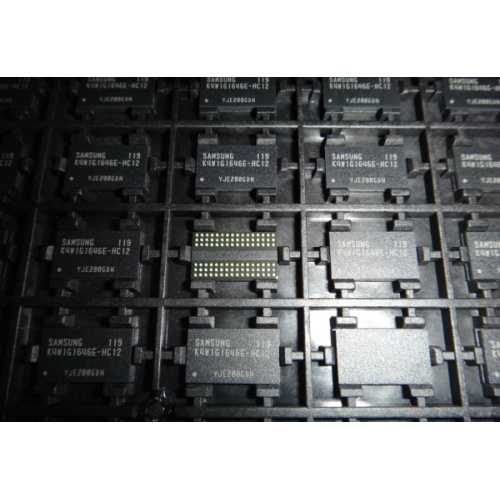

Samsung Original K4W2G1646P-HC12 Spot supply

-

$23.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is BGA soldering?

PCBA Manufacturing, BGA welding generally refers to circuit board welding. Circuit boards, circuit boards, PCB boards, and pcb soldering technologies have developed in the electronics industry in recent years. An obvious trend can be noted is reflow soldering technology. In principle, traditional plug-in parts can also be reflow soldered, which is commonly referred to as through-hole reflow soldering. The advantage is that it is possible to complete all solder joints at the same time, minimizing production costs. However, temperature-sensitive Electronic Components limits the application of reflow soldering, whether it is plug-in parts or SMD. Then people turn their attention to soldering. In most applications, selective soldering can be used after reflow soldering. This will become an economical and effective way to complete the soldering of the remaining plug-in parts, and it is fully compatible with future lead-free soldering.

Tools/Materials:

PCBA

BGA chip

BGA rework station

solder paste

brush

Tin wire

1. Set and adjust the temperature and curve of the BGA rework station to determine the appropriate temperature setting

2. After dragging the PCB pad with tin wire, place the PCBA on the track of the BGA rework station

3. Use a brush to apply paste flux on the PCB pads

4, absorb BGA

5. Optical alignment to prevent deviation of BGA mounting

6. Paste the BGA on the PCBA

7. Soldering for a few minutes, so that the BGA solder ball can be fused with the flux paste and soldered together with the PCB pad

8. Function test to confirm BGA welding quality

Related Keywords