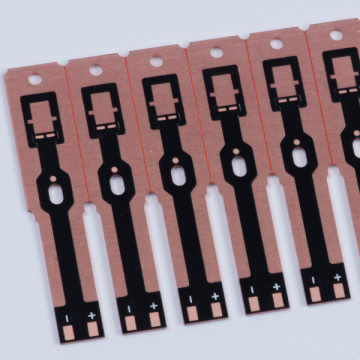

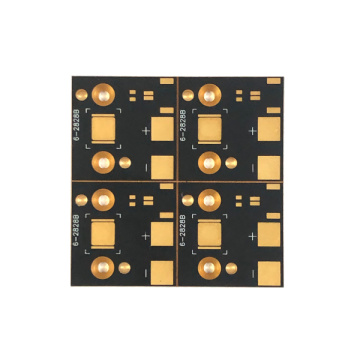

copper base metal core PCB with LED mounted

-

$1.87≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Express, Air

- Port:

- shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10000pcs/day |

|---|---|

| Payment Type: | Paypal,T/T |

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Express,Air |

| Port: | shenzhen |

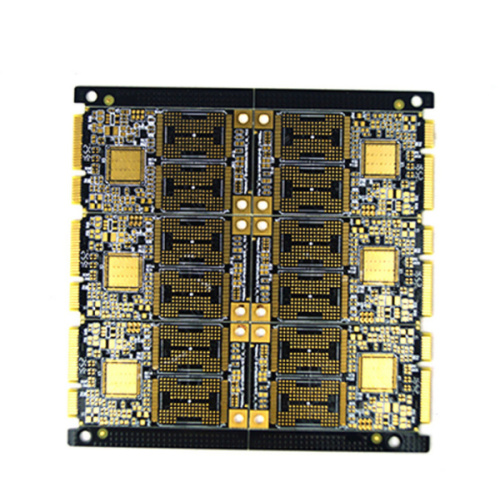

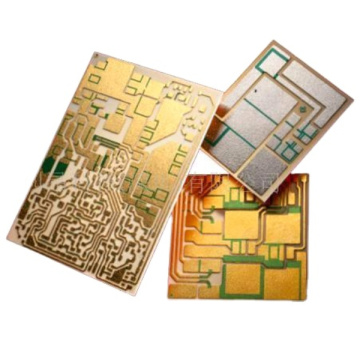

What is metal core PCB?

Metal Core PCB is a thin and flat material used to accommodate various Electronic Components, including origin electronics IC, and used in electronic devices, especially computers. In addition, it also adds a metal layer to provide some Advantages, the most common advantage is that the metal core is more suitable for heat dissipation than other materials, so MCPCB does not need so many fans; Metal Core PCB is also not affected by thermal changes in other PCB dimensions. The disadvantage is that these PCBs are usually thick, so they may not be suitable for every system. Aluminum base board is usually used as a metal core, but copper and alloys are also common.

PCB houses Electronic Components.

When the PCB is running, heat is generated by the power and electrical energy of the system. If the heat is not reduced to a manageable amount, the system can catch fire and reduce the life of the PCB, or the PCB immediately stops working. Fans and heat sinks are usually used to dissipate heat. However, Metal Core PCB uses a metal core inside the PCB, and the metal conducts heat. The performance is good, therefore, the heat is directed to the metal, away from the important area of the PCB.

Thermal expansion is a big problem. Thermal expansion will cause the PCB to expand from exposure to heat. After the PCB expands, it may no longer adapt to the system, or there may be other functional problems. Although Metal Core PCB cannot completely alleviate this problem, it is greatly reduced. This problem is solved. Metal is not susceptible to heat, making PCBA more stable under working conditions.

The main disadvantage of using Metal Core PCB is that the size metal layer is added to the printed circuit board, which will slightly increase the size. Usually the size increases by only about 0.1 inches (2.54 mm), but this is enough to prevent the PCB from being installed in some systems. This means that some compact systems may not be able to use the PCB without certain modifications.

Some metals are stable under the high heat generated by the system. The most commonly used metal for Metal Core PCB is the Aluminum base board, because aluminum is easily copper is the second most common metal, followed by alloys made of other stable metals.

Related Keywords