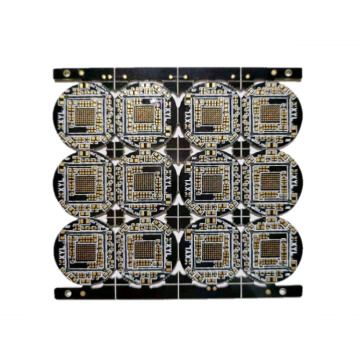

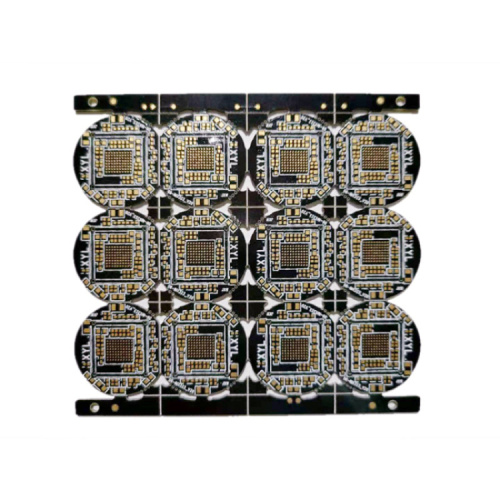

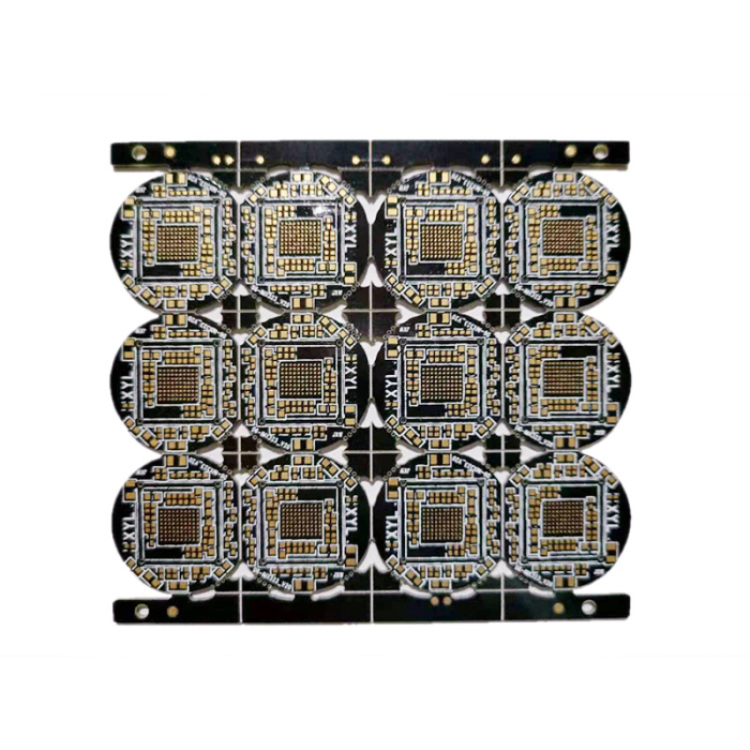

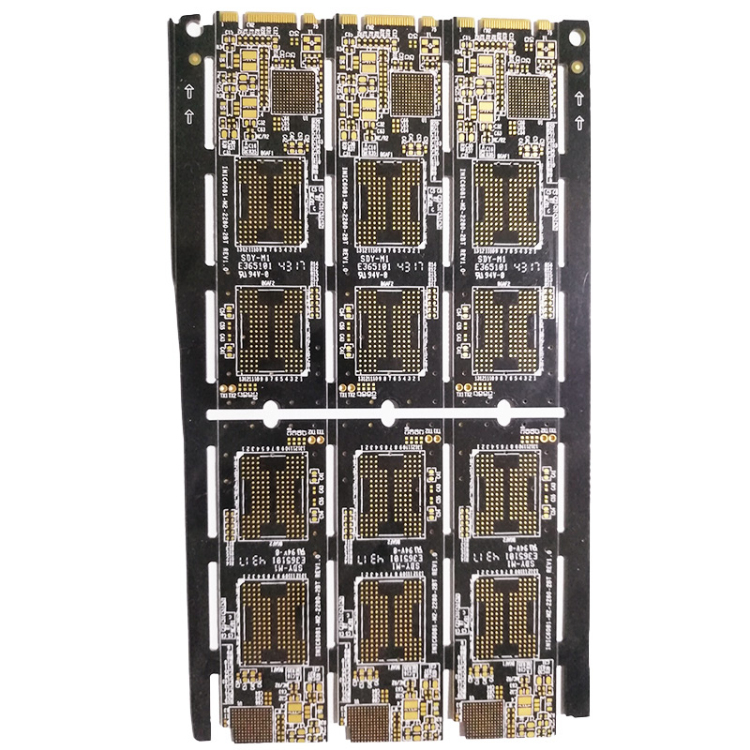

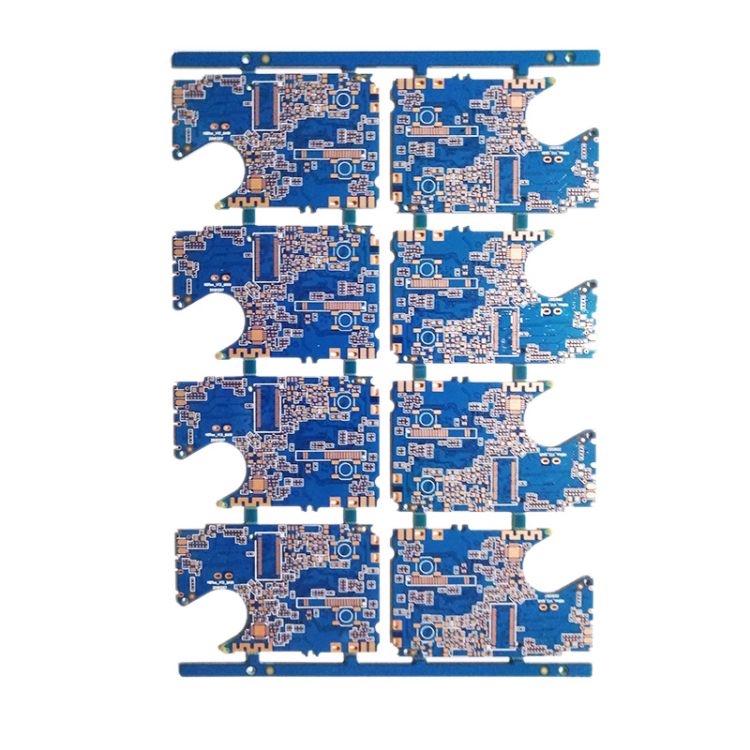

FR-4 Material Quick Turn Double-sided PCB

-

$0.22≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowHow can I make my PCB quality at home?

Electronic enthusiasts, in order to achieve a design goal, to use PCBA to verify its effect, it is necessary to obtain a PCB board, and a PCB board to the factory for production, the cost is too high. You can only make a Low Cost Prototype PCB by yourself at home.

How to make pcb at home:

The schematic diagram is converted into a PCB, and the originals on the customized PCB production are adjusted according to the circuit requirements. After the PCB is made, you need to print out the PCB wiring diagram. The picture is a wiring diagram printed on thermal transfer paper with a laser printer. Then use a thermal transfer machine (electric soldering iron is also possible, but the success rate is relatively low) to transfer to the copper plate. I usually set the temperature to 175 degrees Celsius and go through the transfer machine 3 times.

The copper clad laminate must be cleaned before being transferred, and sanded with 400 or more sandpaper. Today's transfer quality is very good, there are no missing lines. If the lines are missing, you can use "oily marks" to fix them.

The next step is to corrode the copper plate. I generally use ferric chloride to corrode. Ferric trichloride is relatively easy to obtain and can be purchased at any chemical reagent shop in any city. The usual ratio is "ferric chloride: water". The ratio is 1 s2 (by weight).

The corrosion rate is still very fast. It takes about 5 minutes to complete a rope. The only disadvantage of using ferric chloride is that cheap pcb manufacturing solutions must be taken out of the solution to observe corrosion.

Corroded custom PCB manufacturing, as well as cleaning transfer lines and using transfer holes on the PCB, can be cleaned with turpentine and thinner (paint solvent). This is also very easy to buy. It can be sold in any paint shop and the price is very cheap.

In this way, cheap pcb manufacturing can be done at home.

This Quick-turn PCB Prototypes can meet your target requirements.

Related Keywords