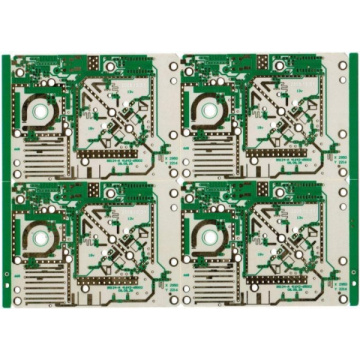

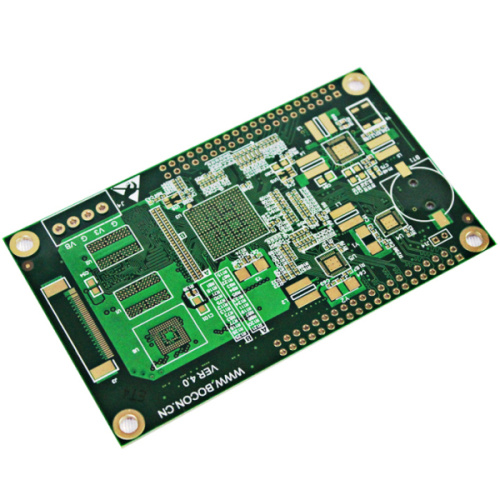

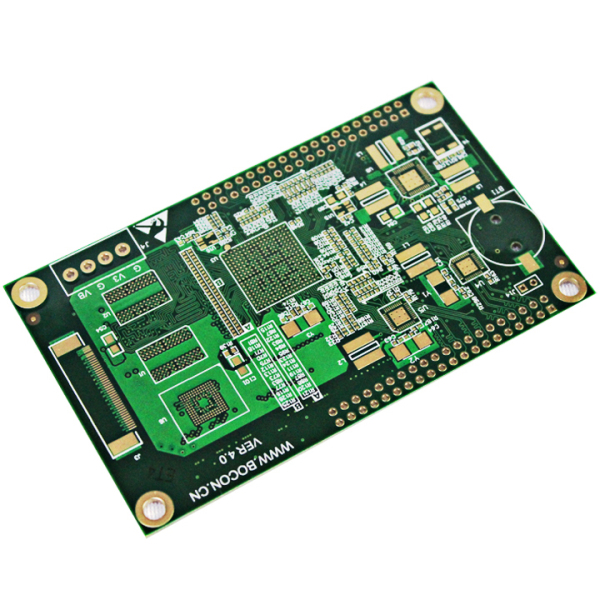

FR4 Double Sided PCB Board 1.6mm Copper

-

$0.10≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowHow to control the cost of PCB assembly?

PCB assembly cost, every electronic engineer or designer wants to know how to get the best PCB assembly quotation and how the price affects the PCB assembly cost. Here are some tips to guide you how to control PCB assembly prices.

First, clearly understand the nature of PCB assembly (PCBA) costs. Some of the biggest cost drivers include:

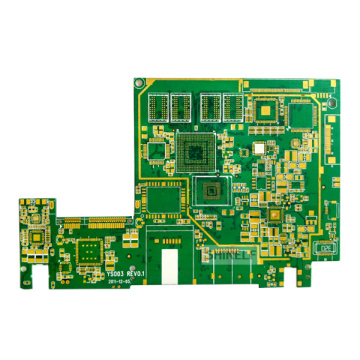

(1) Assembly type surface mount (SMT) (SMD component) through hole (DIP) hybrid (both)

(2) Component placement only requests top-level components to request Doulbe double-sided assembly

(3) Total number of components (SMD + DIP)

(4) Component package size 1206 0804 0603 0402 020101005

(5) Component packaging (reel priority), reel, pipe, pallet, cutting strip with or without tie, loose packaging bag

(6) The required process SMT through-hole is automatically inserted into the through-hole, sliding line, wave soldering automatic optical inspection (AOI) <br> X-ray selective solder manual solder assembly

(7) Quantity and batch size

"Keep Panelize flexible to meet your manufacturer's needs."

You need to ensure that panelization is optimized for the needs of PCBA manufacturers.

(8) Preparation requirements for special parts (ie lead length, minimum/maximum height, spacing)

(9) The total cost of the complete bill of materials (BOM)

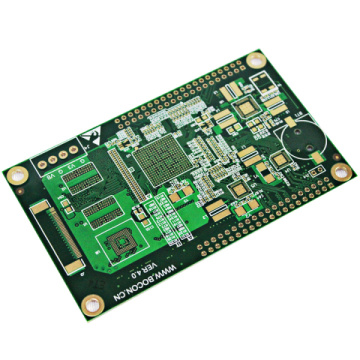

(10) The number of layers of the bare board (PCB) and the materials used

Rigid-Flex Board components cost more than rigid PCB boards

(11) Coating requirements (Medical or military usually requires full coating or selective coating) The number of sprayed or brushed coatings-the coating area specified by the coating tolerance

(12) Potting requirements (if any)

(13) Assembly compliance requirements RoHS (Lead-free) Non-RoHS (Lead-containing) IPC-A-610D Class I, Class II or Class III ITAR

(14) Test requirements (RayMing prefers to test all PCBA boards before shipment, we hope you can tell us how to test) Power-on function circuit test (ICT) cycling without test (visual inspection only)

(15) Transport requirements standard ESD (electrostatic discharge) bag non-standard/special container

(16) Delivery (RayMing provides fast-rotating pcb assembly services)

Standard shift, no rush request to rush fast conversion (labor and material costs are affected)

These 16 tips will affect the PCB assembly price, so you can choose the best one to save costs. When you purchase parts, you can provide multiple component sources for each component. It is easy to control some costs, not only from digikey, Some agents also have a strong price to support a component, reducing cost sources more quickly.

Related Keywords