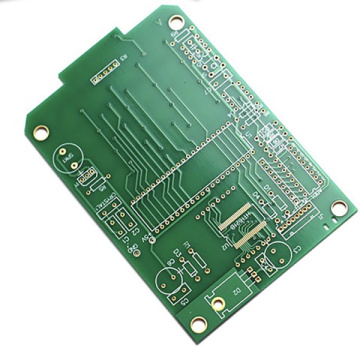

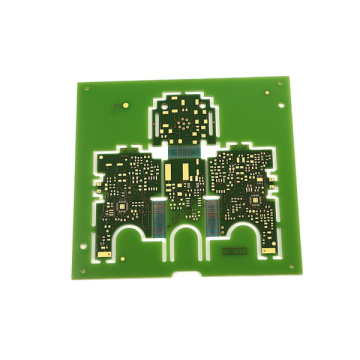

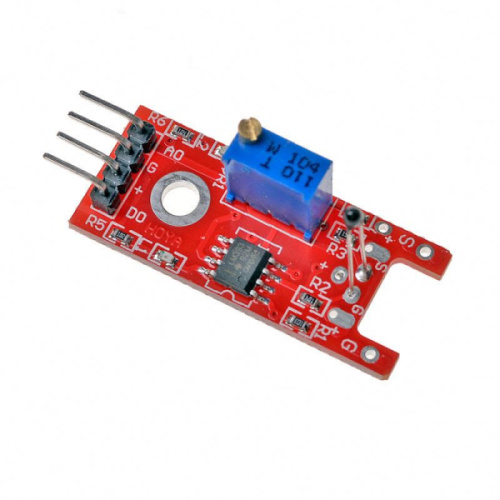

IR Infrared Flame Sensor Flame resistant PCB

-

$10.82≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now

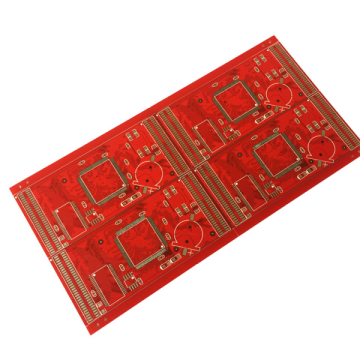

How do you choose a PCB material?

For general electronic products, FR4 epoxy fiberglass substrate is used, for high ambient temperature or for flexible circuit boards, polyimide fiberglass substrate is used, and for High frequency board, Double-sided F4BM350 high frequency board is required; Electronic products with high heat dissipation requirements should use metal base printed boards.

Factors to consider when choosing PCB materials:

(1) A substrate with a higher glass transition temperature (Tg) should be selected appropriately, and the Tg should be higher than the operating temperature of the circuit.

(2) The coefficient of thermal expansion (CTE) is required to be low. Due to the inconsistency of the thermal expansion coefficients in the X, Y, and thickness directions, it is easy to cause PCB deformation, and in severe cases, the metallized hole will break and the components will be damaged.

(3) High heat resistance is required. Generally, PCBs are required to have a heat resistance of 250°C/50S.

(4) Good flatness is required. Surface-Mount (SMT) & BGA Assembly's PCB warpage requirements are <0.0075mm/mm.

(5) In terms of electrical performance, the high frequency board requires materials with high dielectric constant and low dielectric loss. Insulation resistance, withstand voltage strength, and arc resistance must meet product requirements.

Related Keywords