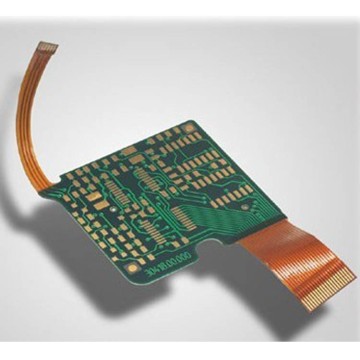

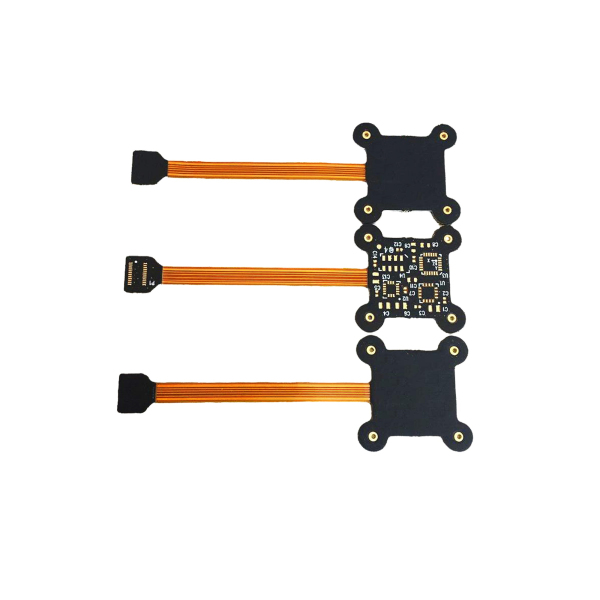

Rigid flex PCB board

-

$0.90≥10000 Piece/Pieces

- Min. Order:

- 10000 Piece/Pieces

- Min. Order:

- 10000 Piece/Pieces

- Transportation:

- Ocean, Land, Express, Air, Others

- Port:

- SZ

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 100000PCS |

|---|---|

| Payment Type: | T/T,Paypal,Others |

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Express,Air,Others |

| Port: | SZ |

Product Description

Product Description

What is the purpose of rigid-flex PCB?

Rigid-Flex Board printed circuit board is a circuit board that combines flexible and rigid board technology in the application. Most rigid flexible boards are composed of multilayer flexible circuit boards that are externally and/or internally connected to one or more rigid boards, depending on the design of the application. The flexible substrate is designed to be in a constant bending state, and usually forms a bending curve during manufacturing or installation.

Rigid-flexible PCB manufacturing applications

Rigid-Flex Board provides a wide range of applications, from military weapons and aerospace systems to mobile phones and digital cameras. More and more rigid flexible board manufacturing has been used in medical devices such as pacemakers because of their space and weight reduction capabilities. The same advantages used by Rigid-Flex PCB can be applied to military weapons and weapon control systems.

Rigid-Flex Board technology and production process.

Whether it is the production of rigid flexible prototypes or the need for large-scale Rigid-Flex PCB manufacturing and

For the mass production of PCB assembly, this technology has been fully verified and reliable. The flexible PCB part is particularly good at overcoming the space and weight problems of space freedom.

Careful consideration of the Rigid-Flex solution and proper evaluation of the available options in the early stages of the rigid flexible PCB design phase will bring significant benefits. It is vital that the Rigid-Flex Board manufacturer is involved in the early stages of the design process to ensure that the design and manufacturing are coordinated and to resolve changes in the final product.

Rigid-Flex manufacturing stage is also more complicated and time-consuming than rigid board manufacturing. All flexible components of Rigid-Flex Board components have completely different processing, etching and welding processes from rigid FR4 boards.

· By eliminating the need for Electronic connectors and Cable Connectors I/O Connectors between various rigid components, the size of the circuit board and the weight of the entire system can be reduced.

· By maximizing space, the number of parts is usually smaller.

· Reduce solder joints to ensure higher connection reliability.

· Compared with the flexible board, the operation in the PCB assembly process is easier.

· Simplified PCB assembly process.

· The integrated ZIF contact provides a simple modular interface for the system environment.

· Simplified test conditions. A complete test before installation becomes possible.

· Using Rigid-Flex Board can significantly reduce logistics and assembly costs.

· The complexity of the mechanical design can be increased, which also increases the freedom of optimizing the housing solution.

Rigid -Flex Des ign and Fabrication Issues

In the Rigid-Flex PCB design process, certain considerations of the final product size change must be considered. In the manufacture of Rigid-Flex boards, once the bonded copper foil is etched away, the flexible polyimide core will shrink. This change must be considered in the design process.

Related Keywords

Related Keywords