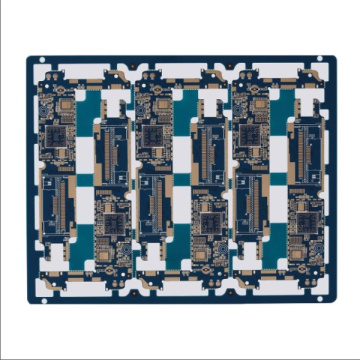

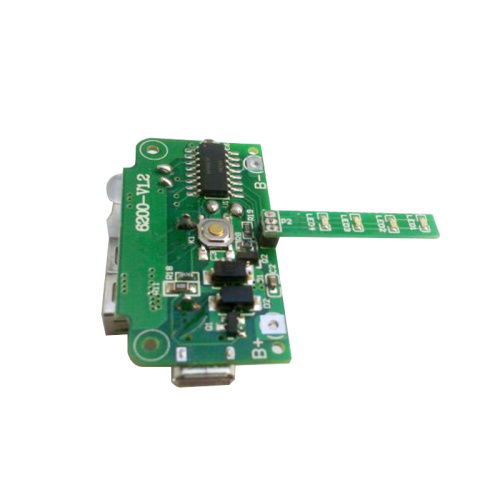

Rechargeable battery board with PCB

-

$0.50≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now

Why is PCB assembly so expensive?

1. Different materials used in PCB cause price diversity

For example, the ordinary double-sided board, the sheet material generally has FR4 (Shengyi, Kingboard, Guoji, three prices from top to bottom), the board thickness ranges from 0.2mm to 3.0mm, and the copper thickness varies from 0.5oz to 3oz. All of these have caused a huge price difference in the sheet material; in terms of solder mask ink, there is also a certain price difference between ordinary thermosetting oil and photosensitive green oil.

2. Different surface treatment processes cause price diversity

Common ones are: OSP (anti-oxidation), lead spray tin, lead-free tin spray (environmental protection), gold plating, immersion gold, and some combination processes, etc. The prices of the above processes become more expensive as they go.

3. The price diversity caused by the difficulty of PCB itself

Two kinds of circuit boards have 1000 holes. One board has a hole diameter greater than 0.2mm and the other board has a hole diameter of less than 0.2mm, which will result in different drilling costs. All types are greater than 4mil, and one type is less than 4mil, which will also cause different production costs; secondly, some designs that do not follow the ordinary board process flow are also extra money, such as half-holes, buried blind holes, holes in the disk, and buttons Board printing carbon oil.

4. The different thickness of copper foil causes price diversity,like Heavy copper board,Microwave radio frequency board,and Etc.

Common copper and platinum thicknesses are: 18um (1/2OZ), 35um (1OZ), 70um (2OZ), 105um (3OZ), 140um (4OZ), etc. The thickness of the above copper foil becomes more expensive as it goes back.

5. Customer's quality acceptance standard

Commonly used are: IPC2, IPC3, enterprise standard, military standard, etc. The higher the standard, the higher the price.

6. Mold fee and test stand

(1) Mold cost. For prototypes and small batches, the general plate factory uses the drilling and milling shape, and there will be no additional milling fees. When making large quantities, mold punching is required, so there is a set of mold costs. The board factory generally quotes above RMB 1,000.

(2) Test fee: The prototype is generally tested by flying probes, and the board factory generally charges 100-400 yuan for the test fee; the test rack is required to test in batches, and the test rack is generally quoted by the board manufacturer between 1,000-1,500 yuan.

Related Keywords