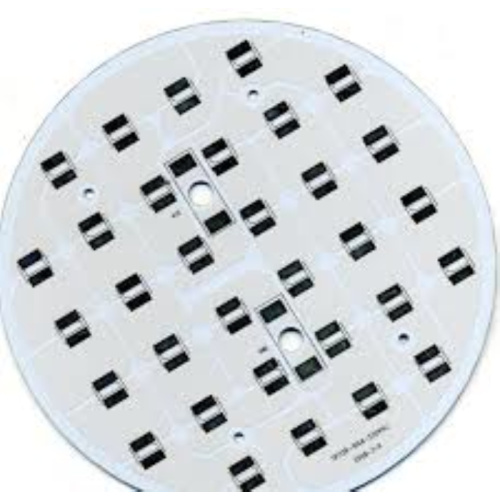

LED light Aluminum Based PCB / Double-Sided pcb

-

$20.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhy is Aluminium used in circuit boards?

Aluminum LED board can actually transfer heat away from vital Electronic Components, thus minimizing the harmful effect it could have on the PCB circuit board. Higher durability: Aluminum provides strength and durability to a product that Roger 4003 printed board or fiberglass bases cannot.

The surface of the power device is Mixed Assembly on the circuit layer, and the heat generated during the operation of the device is quickly transferred to the metal base printed board layer through the insulating layer, and then the heat is transferred from the metal base layer to realize the heat dissipation of the device. Compared with the traditional FR-4, aluminum The substrate can minimize the thermal resistance, so that the aluminum substrate has excellent thermal conductivity; compared with the thick film ceramic circuit, its mechanical properties are extremely good.

In addition,Aluminum LED board have the following unique advantages:

Meet the requirements of RoHs;

More suitable for Surface-Mount (SMT) &BGA Assembly process;

Extremely effective treatment of thermal diffusion in the circuit design scheme, thereby reducing the operating temperature of the module, prolonging the service life, and improving the power density and reliability;

Reduce the PCB Assembly products of heat sinks and other hardware (including thermal interface materials), reduce product volume, and reduce hardware and Turkey PCB Assembly costs; optimize the combination of power circuits and control circuits;

Replace fragile ceramic substrates for better mechanical durability.

Related Keywords