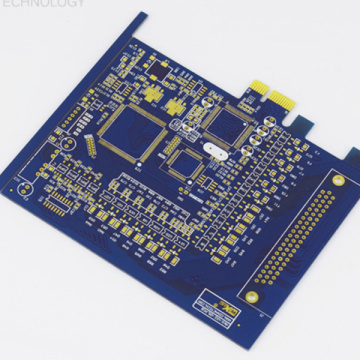

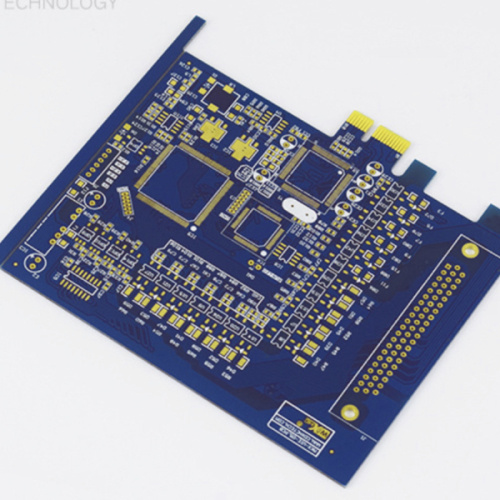

Multi-layered PCB 4Mils Line 0.3mm Minimum Hole Size

-

$32.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now

What are the three types of PCB?

With the development of printed circuit boards in the direction of high-precision, thinning, multilayering, and small holes, the demand for circuit boards is also increasing, but many friends are not very clear about some types of circuit boards. I will talk about it in detail.

type of circuit board

1, single-sided circuit board

Single-sided printed circuit board includes only one layer of substrate. One end of the substrate is coated with a thin layer of metal, usually copper, because it is a good electrical conductor. Generally, a protective solder mask is located on the peak of the copper layer, and a final silk screen coating can be applied to the top to mark the board's components.

The PCB is composed of a single circuit and electronic components. This type of module is most suitable for light-hearted electronic products, and beginners usually design and build this type of circuit board first. Compared with other types of circuit boards, the cost of these circuit boards is lower than mass production. But despite their low cost, they are rarely used due to their own design limitations.

2, double-sided circuit board

This type of PCB is more familiar than single-sided boards. Both sides of the substrate of the pcb board include metal conductive layers, and the components are also attached to both sides. The holes in the PCB connect the circuits on a single circuit to the circuits on the other side.

These circuit boards are used to connect the circuits on each side through one of two technologies: through-hole and surface mount technology. Through-hole technology can call small wires (through holes) as leads, and solder each end to a suitable part.

Surface mount technology is different from through-hole technology and does not use wires. In this place, many small pencils are soldered directly on the board. Surface mount technology allows many circuits to be completed in a smaller space on the circuit board, which means that the circuit board can perform more functions, usually with a smaller weight and faster speed than a through-hole board.

These PCB boards further expand the density and complexity of PCB design by adding additional layers beyond the top and bottom layers seen in the double-sided configuration. With multiple levels of accessibility in multilayer printed circuit board configurations, multilayer PCBs enable designers to produce very thick and highly composite designs.

The extra layer used in this design is the power plane, they all provide power to the circuit and also reduce the level of electromagnetic interference emitted by the design. A lower EMI level is obtained by placing the signal level in the middle of the power plane.

4, rigid circuit board

In addition to having different layers and sides, printed circuit boards may also change inflexibility. Most customers usually consider the inflexible PCB when they image the circuit board. Rigid printed circuit boards use solid rigid substrates, such as fiberglass, to keep the board from twisting. The motherboard in a computer tower is the best example of an inflexible PCB.

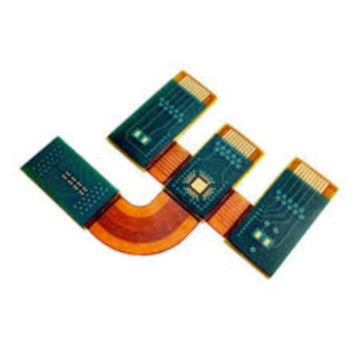

Generally, the substrate in the flexible board is a flexible plastic. This basic material allows the circuit board to be adapted to a form in which the unbent board cannot be rotated or moved during use, without affecting the circuit on the printed circuit board.

Rigid flexible board combines the technology of flexible and rigid circuit boards. A simple rigid flexible board includes a rigid circuit board connected to the flexible circuit board. These boards can be more complex if required by the design requirements.

Related Keywords