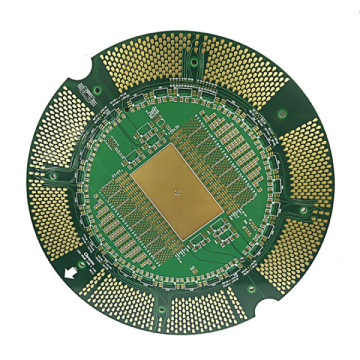

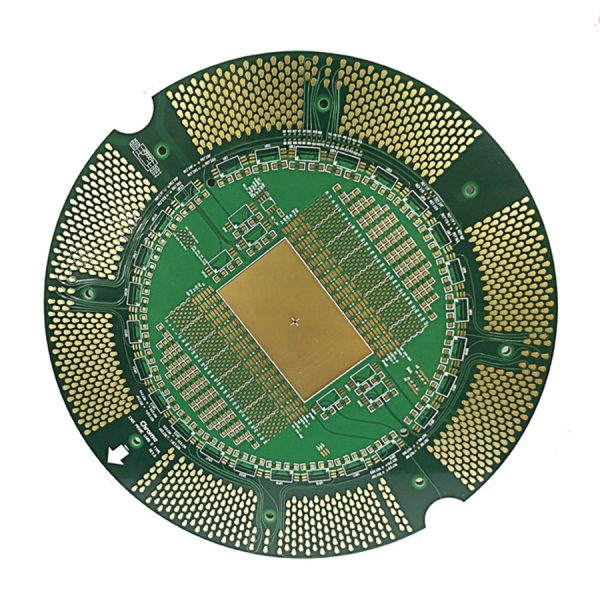

PLATED HALF HOLE CIRCUIT BOARD

-

$9.02≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is the military level PCB?

Military toughness is one size fits all. Not only strong personnel, but also electronic equipment and computers used on site. Of course, this means that printed circuit boards (PCBs) used in the defense sector need to be as hard as nails. Although designing a commercial PCB is not easy, designing and manufacturing military-grade PCBs requires special attention to durability and compliance. All components must be able to withstand harsh environments.

The requirements for military-grade electronic PCBs include:

Compared with 5-10% of commercial grade electronic PCB, the minimum tolerance (between 1-2%).

Expected product life to be extended by 5 – 15 years

Ability to handle extreme conditions

Strict and specific design and layout technology

Higher reliability, stronger, stronger

Achieving each of these conditions requires adequate preparation and consideration from the design stage.

In order to understand the importance of the correct use of military-grade PCBs, here are some applications that rely on military-grade PCBs:

Base and camp protection and security system

Unmanned vehicles, military artillery and mortars

Robot system

Ruggedized computer

Defense Navigation and Communication System

Satellite subsystem using embedded processor

OEM engineers engaged in military-grade electronic design need to fully understand the design considerations that are critical to reliability and high-quality performance.

General design considerations for military-grade electronic products

All PCBs belonging to this category should meet MIL specification level standards and pass the highest performance and functional tests. General considerations for military PCBs include:

Military-grade PCBs should handle the maximum current load.

There should be a clear distinction between low-frequency and high-frequency components. For example, certain high-frequency components may produce waveforms that affect low-frequency components. These waveforms increase noise and reduce signal quality. For the military, this is unacceptable.

All clock signals should be clean and shielded.

In order to make the current transmission smooth, all PCB wiring should maintain a 45° angle or less.

Finally, all military-grade PCBs should be manufactured in strict accordance with MIL-PRF-50884, MIL-PRF-55110 and MIL-PRF-31032 standards.

After you are familiar with the design requirements, you should also consider the best PCB substrate types for designing and manufacturing military-grade electronic PCBs.

Only the best quality and heat-resistant materials can be placed on the table. Military-grade electronics are often used in harsh conditions, including high temperatures. Even under these conditions, the PCB should be able to withstand and have a high level of performance.

If heat dissipation is required, thermal paste should be used. Decoration materials should also be carefully considered. They should support PCB operation in harsh environmental conditions.

High-quality materials that can withstand extreme weather and temperature are a must. At this stage, an in-depth understanding of the different composite materials, substrates and elements used in PCBs is invaluable.

They must meet specific rigidity, flexibility, electrical and thermal requirements to be considered military grade. Some of the best materials for military PCB boards are:

aluminum

copper

High temperature laminate

In some cases, anodized aluminum is also used to minimize the effects of thermally induced oxidation.

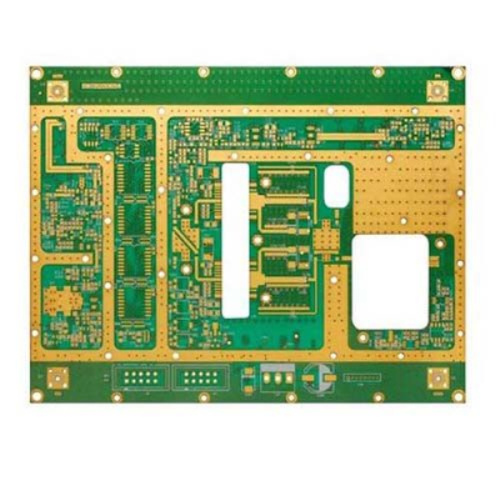

Coating and surface treatment

The military has specific requirements for surface treatment to protect PCBs from harsh environmental conditions, including dust, water, vibration, and extreme temperatures. Therefore, coating and surface treatment are important features of military-grade electronic products. The copper coating protects the PCB from rust.

According to the function of PCB, there are a variety of surface treatment materials to choose from:

Hot Air Solder Leveling (HASL)

Electrolytic wire bond alloy

Shen Yin

Lead-free spray tin

Electrolytic nickel and gold

Electroless nickel plating with immersion gold coating

Acrylic or acid-based sprays can also be used for conformal coatings on PCBs to further protect them from weather and other external factors.

Durability

Durability and reliability are the main concerns of the military. More importantly, these components are used under less than ideal conditions and will be damaged due to damage such as solder cracking.

On average, military electronic equipment has a service life of 5 to 15 years, ensuring durability, reliability, and service life, thereby minimizing vibration of installed components.

For many military PCBs, through-hole mounting is the recommended mounting method during PCB assembly. Circuit boards manufactured using Through-Hole Assembly technology are very durable. In addition, this method uses soldering on the top and bottom of the circuit board to establish a strong physical connection between the component and the circuit board.

Thorough testing is essential to confirm the reliability and durability of the PCB in actual applications. For military PCBs, the MIL-STD-202 standard is the basis of all electronic product testing methods.

After the PCB meets the design of manufacturability considerations, various tests can be carried out, including:

X-ray inspection-also known as AXI, this test checks various defects such as solder connections, barrels, and internal wiring before the PCB enters full manufacturing.

Functional test-The ancient functional test checks whether the PCB will be energized. How to perform functional testing depends on the application.

Military PCBs can also perform various other tests, including:

Solderability test

PCB contamination test

Time domain reflectometer (high frequency board)

Float welding test

MIL-STD/ITAR/NADCAP: Learn about different certifications and their applications

MIL-STD, ITAR, NADCAP...It is easy to get lost in the alphabet soup of military, defense and aerospace certification.

Many original equipment manufacturers often confuse each other, thinking that only one certification is sufficient instead of all three certifications.

Military standards:

The MIL-STD standard covers the final characteristics of the product, as well as the production process, materials and safety standards. MIL-STD includes five types of defense standards:

Interface standard

design standards

Manufacturing process standards

Standard practice

Test method standard

These national defense standards are designed to ensure the proper performance and logistical effectiveness of military equipment.

ITAR:

The ITAR standard focuses on military equipment and sensitive information that may involve military equipment. There are many aspects of product development that are subject to ITAR regulations-some obvious but not so obvious:

Design information

Development information

Production Process

Manufacturing steps

Assembly drawing

Repair process of specific components

Test protocol

Revise

High-quality electronic contract manufacturers should verify in advance whether they must comply with ITAR during the quotation process. In this way, it can ensure that everyone involved in the process complies with the ITAR compliance checklist.

Nadcap:

Nadcap is a certification program for companies in aerospace-related industries. Nadcap certification is issued at the company level for specific processes, such as:

coating

Chemical processing

Heat treatment

Conventional processing

welding

Non-destructive testing

These standards usually work together. Generally, some technologies produced under MIL-STD compliance will be exported under ITAR regulations. Nadcap certification plays a role in the construction process such as heat treatment and coating.

For MIL-STD grade electronic products, ensuring that your electronic contract manufacturer has the latest MIL-STD, ITAR and Nadcap certification will ensure that your PCB is suitable for all military grade applications and sales

Related Keywords