The difference between ENIG and gold plating

-

$7.00≥2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Transportation:

- Ocean, Air, Express, Land, Others

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Paypal,Others |

|---|---|

| Incoterm: | FOB,CIF,EXW |

| Transportation: | Ocean,Air,Express,Land,Others |

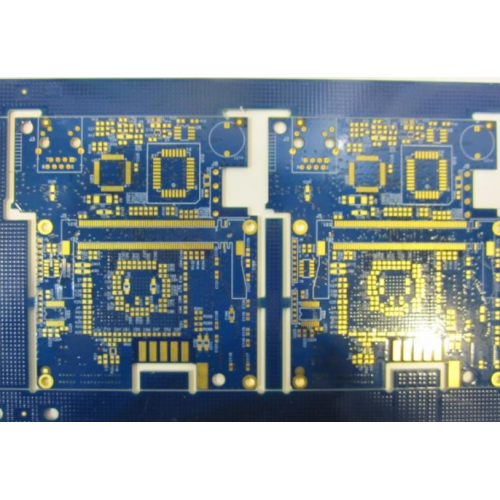

What's the difference between ENIG and gold plating?

Immersion Gold (ENIG, Electroless Nickel Immersion Gold)

Advantages: It is not easy to oxidize, can be stored for a long time, and the surface is flat, suitable for welding small gap pins and components with small solder joints. The first choice for PCB boards with buttons (such as mobile phone boards). Reflow soldering can be repeated many times without reducing its solderability. It can be used as a substrate for COB (Chip On Board) wire bonding.

Disadvantages: high cost, poor welding strength, because the electroless nickel plating process is used, it is easy to have the problem of black disk. The nickel layer will oxidize over time, and long-term reliability is a problem.

Applicable scenarios: Immersion gold process is different from OSP process. It is mainly used on boards with functional connection requirements and a long storage period on the surface, such as the keypad of a mobile phone, the edge connection area of the router housing and the elastic connection of the chip processor Electrical contact area. Due to the flatness problem of the tin spray process and the removal of the flux of the OSP process, immersion gold was widely used in the 1990s; later, due to the appearance of black disks and brittle nickel-phosphorus alloys, the application of immersion gold was reduced. , But at present almost every high-tech PCB factory has sinking gold wire. Considering that the solder joint will become brittle when removing the copper-tin intermetallic compound, there will be many problems in the relatively brittle nickel-tin intermetallic compound. Therefore, portable electronic products (such as mobile phones) almost all use copper-tin intermetallic compound solder joints formed by OSP, immersion silver or immersion tin, and immersion gold is used to form the key area, contact area and EMI shielding area, which is the so-called selective Immersion gold craft. It is estimated that about 10%-20% of PCBs currently use electroless nickel/immersion gold processes.

The difference between Immersion Gold and Gold Plated:

Immersion gold uses a chemical deposition method, which generates a layer of plating through a chemical oxidation-reduction reaction method, which is generally thicker. It is a kind of chemical nickel-gold layer deposition method, which can reach a thicker gold layer. Gold plating uses the principle of electrolysis, also called electroplating. The surface treatment of other metals is mostly electroplating.

Immersion gold is different from the crystal structure formed by gold plating. Immersion gold boards are easier to weld than gold-plated boards and will not cause poor welding;

The immersion gold board only has nickel and gold on the pad, and the signal transmission in the skin effect is on the copper layer without affecting the signal;

Immersion gold is denser than gold-plated crystal structure, and it is not easy to oxidize;

The immersion gold board only has nickel and gold on the pads, and will not produce gold wires that cause shortness;

The immersion gold board only has nickel and gold on the pad, and the solder mask and the copper layer on the circuit are more firmly combined;

Immersion gold is golden yellow, more yellow and better-looking than gold plating;

Immersion gold is softer than gold plating, so it is not as good as gold plating in terms of wear resistance. For gold finger plates, the effect of gold plating will be better.

Related Keywords