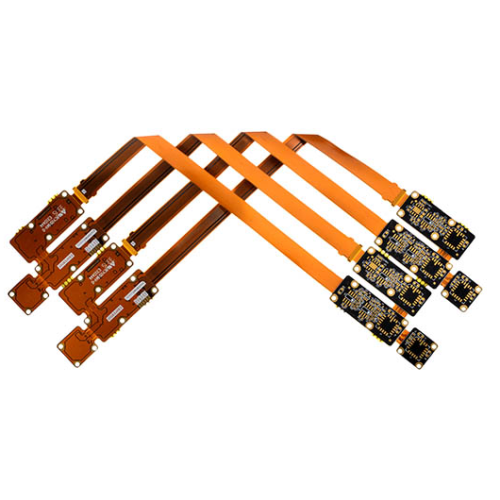

specialize in manufacturing rigid-flex PCB

-

$0.70≥2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Paypal,Others |

|---|---|

| Incoterm: | FOB,FCA,DDP |

| Transportation: | Ocean,Land,Air,Express,Others |

What is the advantage of rigid-flex PCB?

1. It can effectively save the space on the circuit board and eliminate the use of Electronic connectors or HotBar technology

Combined with Rigid-Flex Board, it can save the space needed to use Electronic connectors or HotBar process. For some circuit boards with high density requirements (HDI CB), one less Electronic connectors is needed. Space is like finding a treasure.

In this way, it also saves the cost of parts using Electronic connectors or the cost of HotBar technology. In addition, by eliminating the need for Electronic connectors, the space between the two boards can be made more compact.

2. Shorten the signal transmission distance, increase the speed, and effectively improve the reliability

The traditional signal transmission through Electronic connectors is "circuit board→Electronic connectors→flexible board→Electronic connectors→circuit board", while the signal transmission of the flexible and hard composite board is simplified to "circuit board→flexible board→circuit board", and the signal transmission is shortened The distance between different media also reduces the problem of signal transmission attenuation between different media. Generally, the circuit on the circuit board is made of copper, and the contact terminals of the electronic connectors are gold-plated, and the solder pins are fully tin-plated. Moreover, solder paste is required on the circuit board, and the signal transmission between different media will inevitably be attenuated. If it is replaced with a Rigid-Flex Board, these media will be reduced and the signal transmission capability will be relatively improved. , For some products that require high signal accuracy, it helps to improve their reliability.

3. Simplify product assembly and save assembly man-hours

Using Rigid-Flex Board can reduce the working hours of Surface-Mount (SMT) & BGA Assembly, because the number of Electronic connectors is reduced. It also reduces the working hours of Mixed Assembly, because it eliminates the Box Build Assembly action of inserting the electronic connectors of the soft board, or eliminates the HotBar process. It also reduces the cost of parts management and inventory, because the BOM is reduced, so management becomes less.

Related Keywords