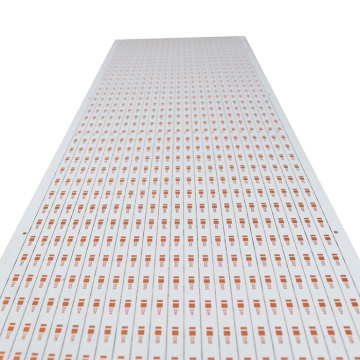

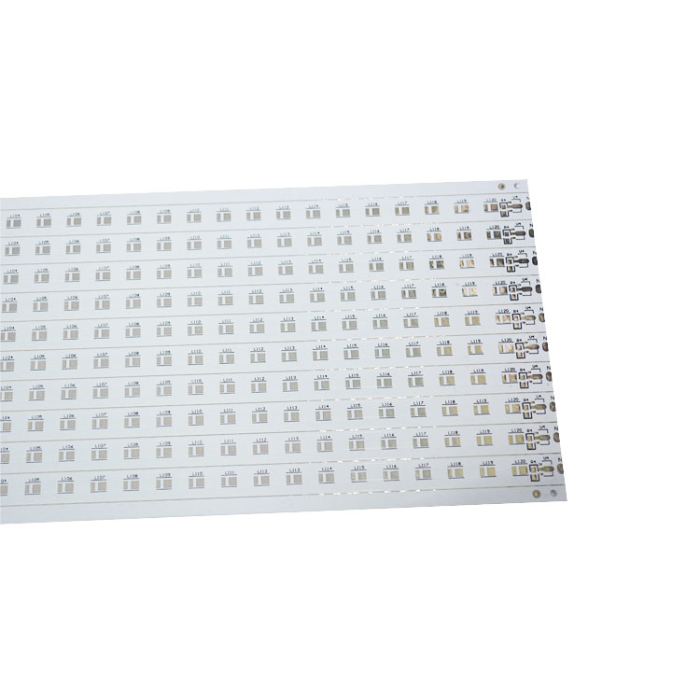

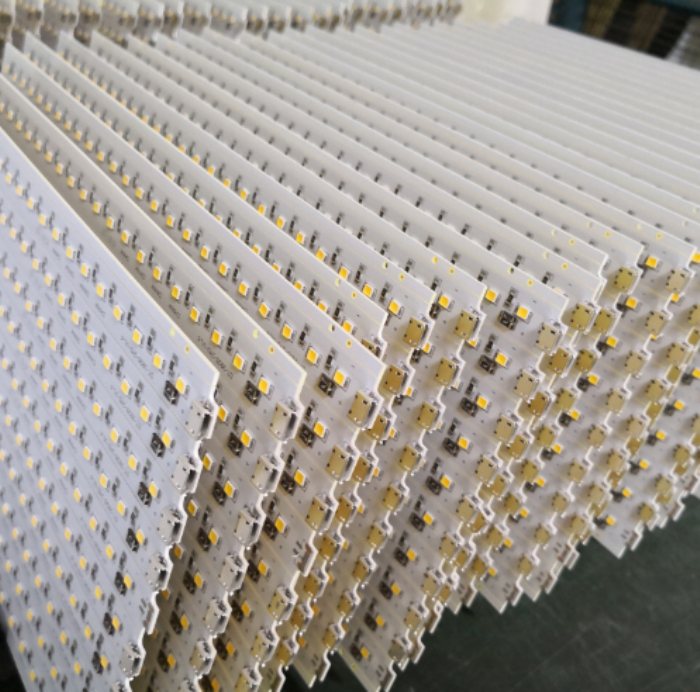

Aluminum t8 led tube lights pcba

-

$1.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now

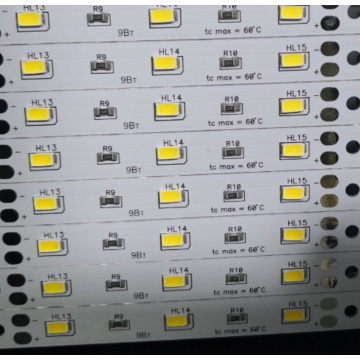

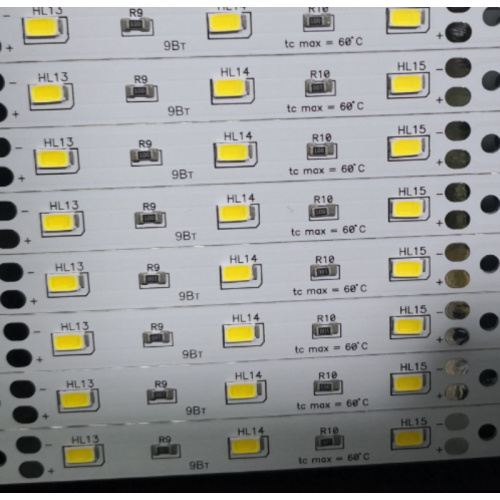

The improvement of PCB is becoming a reliable electronic solution for LED lighting of many OEM, EMS and other manufacturing units for adjusting their products through high-end customization. It has universal applications, whether it is for home, corporate use, aerospace, urban street lighting, projection systems, hotels, infrared heating, industrial use, automobiles, medical operations, hotels and other markets for lightning systems. The biggest challenge facing LED lamp manufacturers is to integrate the correct type of metal base printed board into the product.

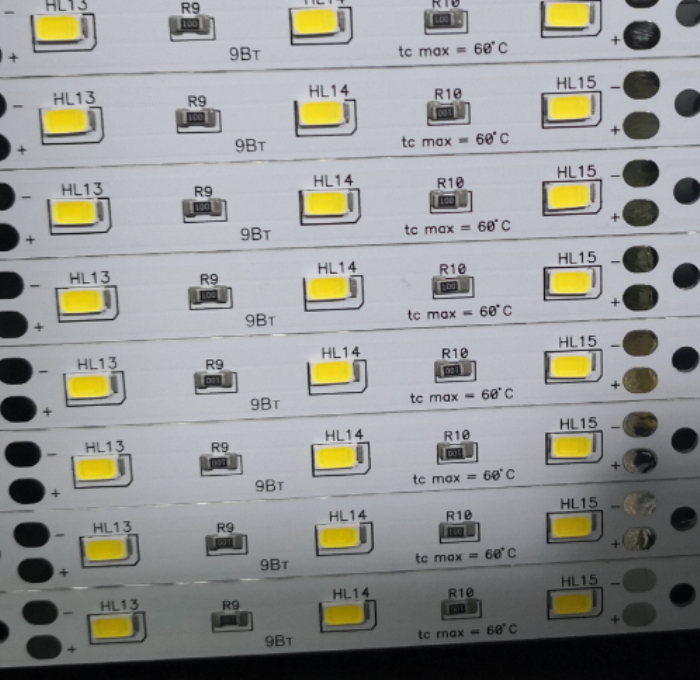

In order to obtain accurate and optimal electronic solutions, certain aspects are critical to design considerations for the proven LED circuit board layout. This includes the heat, the size of the components, where the energy loss should be dissipated, the proper location of the heat source, the equilibrium temperature, the cooling system and the proper heat sink. Provides a perfect electronic solution for the system behavior of LED lights. The printed circuit board is manufactured with the most advanced technology and technology, including FR4 epoxy resin and glass fiber PCB, which allows heat dissipation on a large surface and improves heat dissipation. FR4 PCB with heat flux Hole array, in which PTH (Plated Through Hole) technology is used together with the configuration of thermal vias to vertically enhance thermal resistance, and thick copper plates using "iceberg technology" are used in high-power LEDs and effective cooling systems in the case of PCBs The FR4 technology requires proper heat distribution and heat dissipation, IMS (insulated metal substrate) is used for higher thermal conductivity, thick film or thin film technology, etc. e are implemented in PCB components to meet the exact requirements of LED lighting.

Related Keywords