Automatic Tunnel Finisher for Garment

-

$5000.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

QX-1000 Automatic Tunnel Finisher for Garment(Require external boiler)

Lingchuang Tunnel Finisher, it's an automated solution with high efficiency on finishing/ ironing of

textiles. It applies all kinds of garments textiles on the market, including challenging natural fiber.

Machine use for ironing, drying and disinfection of large batch of garments. An hourly efficiency

around 1200 pieces, maximizes your output. Greatly save manpower and cost, improves ironing

efficiency. Apply to all large-scale garment factories.

Applicable OF Steam Ironing Machine

Suitable for most kinds of knitting, woven fabric, leather, cotton, hemp, chemical fiber, silk, chiffon,

blended fabric etc .

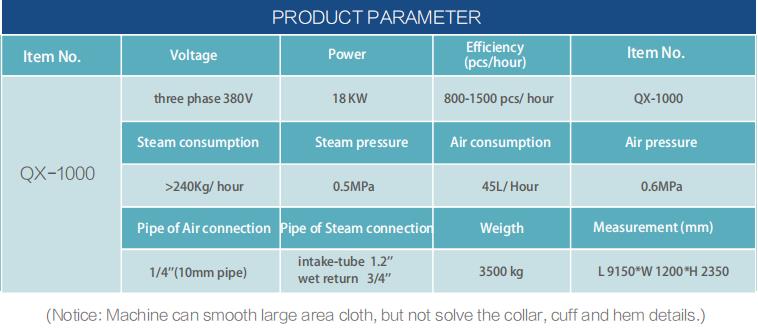

Steam Tunnels Efficiency:

800-1200 pcs per hour, daily output around 12000 pcs, with 1 operator.

Measurement:

L9150mm,W1200mm,H 2350mm. Hoisting is needed if going upstairs.

Tunnel Box Ironing Machine Advantage:

1. High efficiency: Daily output around 12000 pcs, with 1 operator, greatly saves labor cost. Also saves

the ironing table space.

2. Convenient Touch panel: Operator can adjust temperature and steam parameter on machine touch

panel flexibly. The parameter datas for different fabrics can be set and saved for easy to switch. Different

fabrics need to adjust different temperature and steam in order to achieve the best ironing effect.

3. Guidelines for daily use: There are clear parameter adjustment guidelines for different clothing fabrics

(cotton, polyester, spandex, etc.), for a better control on the shrinkage rate.

4. Air water separation technology: Unique air water separation technology, can separate 99.5% water in

steam, makes fabric without water stains after ironing, saves manual drying process and time.

5. Unique ironing technology patenting by Lingchuang, through ironing by the machine, clothing color

molecules can be activated, make fabric more vivid.

6. The extended air module (total 4 air module) increase performance optimized finishing result.

7. Section design of high-speed input device, the capacity can reach to 1200 pieces/hour, not easy drop

clothes, no multiple pieces of input stacking phenomenon.

8. Machine can be set up to connect to hanger system.

Related Keywords

Related Keywords