Stainless Steel Air Compressor Filter With Floating Valve

-

$592.001-19 Piece/Pieces

-

$562.00≥20 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Shanghai , Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500PCS PER DAY |

| Supply Ability: | 500PCS Per Days |

| Payment Type: | L/C,T/T |

| Certificate: | CE |

| HS Code: | 842139 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai ,Guangzhou |

Compressed air contains difffferent types of pollutants. These pollutants must be treated and reduced to acceptable levels to ensure the safe, effiffifficient and economic operation of the compressed air system.

Most industrial compressed air applications operate at 7, 10, or 13 bar pressure, and purifification equipment is usually designed around these working pressures.

However, some application industries require higher working pressure, which will also increase the concentration of pollutants. Stainless Steel Filter, designed to remove liquid aerosols, water, oil and sub-micron particles in the compressed air system, the filtration efficiency can be up to 99.99%, remove 0.01 micron particles and small droplets, improve the product pas rate, reduce maintenance time and cost, improve production effiffifficiency Pass rate, reduce maintenance time and cost, improve production efficiency and ultimately reduce production costs.

Advantages of Stainless Steel Compressed Air Filter

①Stainless steel material, 304, 316, 316L optional, resistant to acid and alkali chemical corrosion environment, the shell warranty period is 15 years; the filter element is 4000-6000 hours;

②Deep-wrap filtration, with a filtration performance of 99.99%, suitable for marine operating platforms;

③The double-layer stainless steel filter element support net makes the filter element stronger and prevents secondary pollution;

④Precise thread processing technology, good sealing performance and easy installation, low pressure drop;

⑤Working pressure can be customized

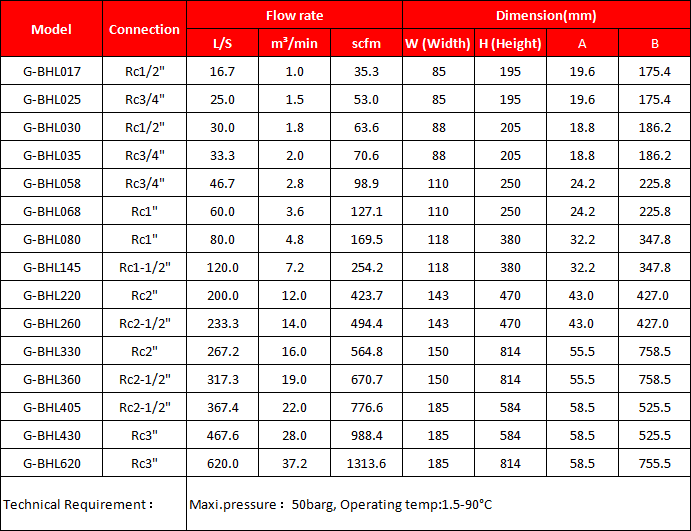

Technical Specification

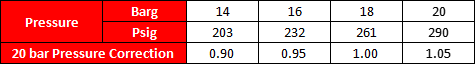

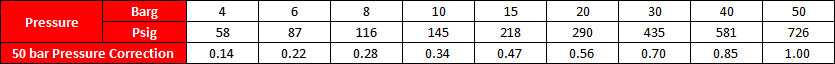

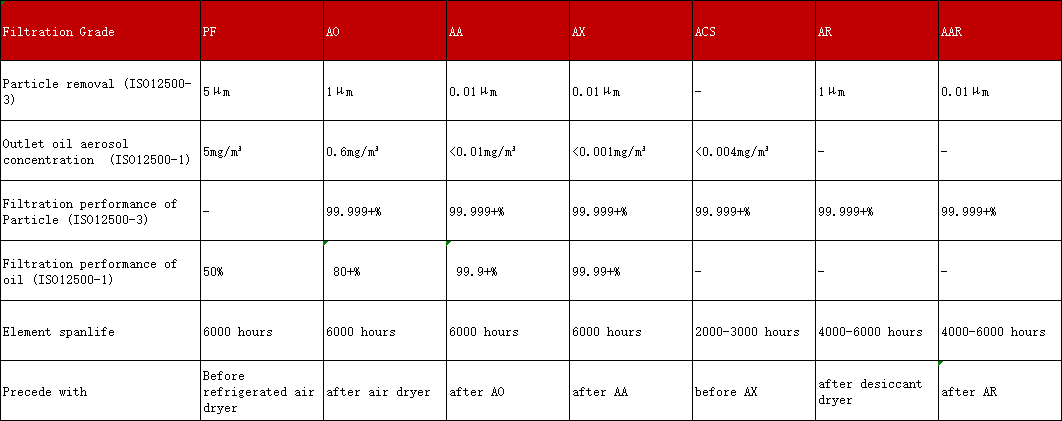

The flow rate below is the treatment capacity of compressed air under rated working pressure 7 barg (100psi g). For the application in other working pressure, please refer to the correction factors.

Element Performance

|

|

|

|

|

|

|

| PF | AO | AA | AX | ACS | AR | AAR |

| As a primary filter, particles whose diameter more than 5μm can be removed, the maximum residual oil contect is negligible. | High efficiency general protection, dust particles, water mist and oil mist whose diameter more than 1μm can be removed, the residual content of oil mist does not exceed 0.6mg/m³(21ºC), 1ppm(w). | High efficiency oil removal filtration, dust particles, water mist and oil mist whose diameter more than 0.01μm can be removed, the residual content of oil mist does not exceed 0.01mg/m³(21ºC), 0.01ppm(w). | Ultra-efficient filtration, dust particles, water mist and oil mist whose diameter more than 0.01μm can be removed, the residual content of oil mist does not exceed 0.001mg/m³(21ºC), 0.001ppm(w). | Dust particles whose diameter more than 0.01μm, oil vapor and odor can be removed, the maximum residual residual content of oil vapor does not exceed 0.003mg/m³(21ºC), 0.003ppm(w). | Dust particles whose diameter more than 1μm can be removed. | Dust particles whose diameter more than 0.01μm can be removed. |

International test and measurement standard ISO12500

>ISO 12500 has made clear a general test and definition method for the compressed air filter manufacturers. The main performance parameters

are the air inlet oil content and particles size distribution of the solid particles.

>ISO12500-1 specifies the test requirements for the filtration performance of oil aerosol in the coalescing filter.

>ISO12500-2 specifies the test requirements of adsorption filters for the removal performance of steam adsorption.

>ISO12500-3 specifies the requirements for removal of particulate matter from solid pullutants.

Products are tested with the international advanced testing equipment based on standard ISO12500,

which is equivalent to the standard ISO8573.

Why choose YUKA as your long term business partner?

Stainless Steel Compressed Air Filter are ideal solutions for removing pollutants in compressed air systems and saving energy. Use imported quality filter materials and design technology to ensure high-quality compressed air quality and lower operating costs.

We have a full set of testing equipment imported from Europe. Filters and gas-water separators can be tested and rated according to ISO 8573.1: 2009

air quality standards, and provide performance test reports.

Packing & Shipping

Packing: Good packing will protect the goods from damage during transport. We use strong, durable packing material to pack the goods.

Shipping: By air,by sea ,by express

Related Keywords

-

15 Years Lifespan Air Filter Housing Compressed Air Line Filter 1.0mpa for Heavy Duty Applications

1/2 Inch NPT Inlet/Outlet Connection Aluminum Compressed Air Filter Unique Lock Design Pressure Loss About 0.25 Bar

Cyclinder Stainless Steel And Doule Support Aluminum Compressed Air Filter 1/2 Inch NPT Inlet/Outlet Connection Industrial

Extended Service Life Air Compressor Oil Filter with Unique Lock Design and Bleed Valve

Modular series filters for large flow