Compressed Air Filter Working Principle

-

$376.071-19 Piece/Pieces

-

$357.26≥20 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, GUANGZHOU, SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500pcs per day |

| Supply Ability: | 500pcs per day |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW,CFR |

| Certificate: | CE |

| HS Code: | 8421399090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,GUANGZHOU,SHANGHAI |

The working principle of compressed air filter

1. Gravity

In compressed air, oil droplets with particle diameters ranging from 20μm to 50μm will directly gather at the bottom of the filter under the action of gravity. The greater the airflow velocity, the lower the filtration efficiency;

2. Inertial collision

Large-area particles with a diameter greater than 1μm are not consistent with the airflow path. The greater the airflow velocity, the higher the collision rate and the better the effect.

3. Direct intercept

The airflow of particles with a diameter of 1μm to 0.3μm is intercepted and separated by the fiber layer at 1/2 of the filter element. The smaller the particle, the lower the interception efficiency.

4. Diffusion

Particles with a diameter of less than 0.3μm are too small for liquid versatility. The irregular Brownian motion generated at this time is inconsistent with the air flow path. The smaller the particle, the more intense the Brownian motion and the greater the probability of capturing.

Feature & benefit

①Integrated die-casting technology, filter housing with 90 kg.f burst pressure-bearing, enjoy 15 years warranty for filter housing

②High filtration performance. With borosilicate fiber glass material, 96% porosity dirst holding ability. 7 layer design for filter element

③Anti-corrosion treatment for inside and outside, prevent second pollution, decrease maintenance cost for owership

④Low Pressure Drop COntrolled, saving energy and saving money

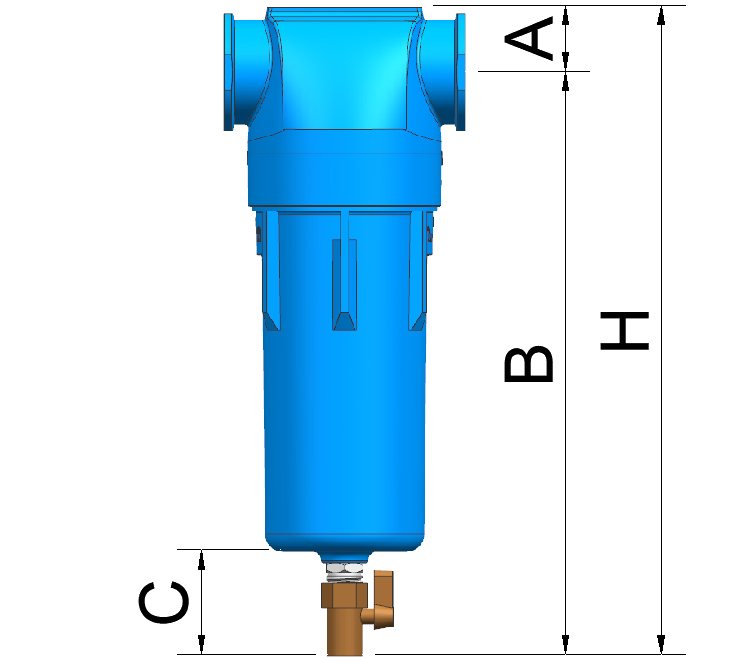

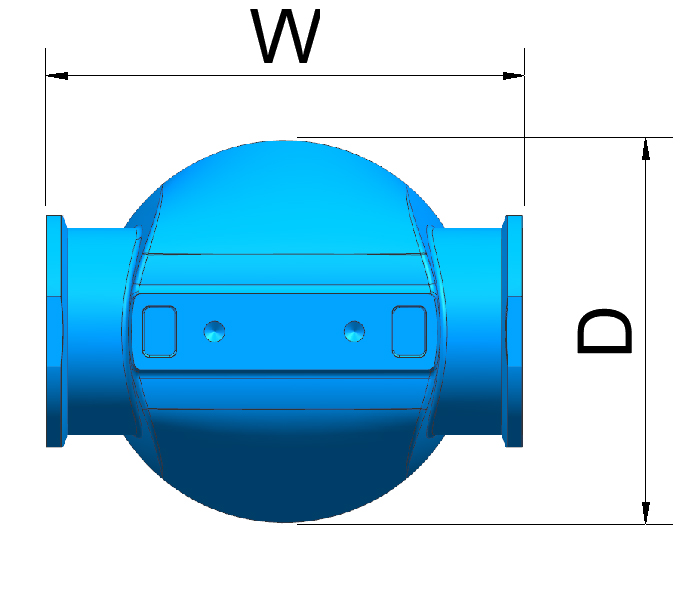

Technical Specification

Model

Pipe size

Flow rates

Dimension (mm)

L/S

m³/min

scfm

W (Width)

D (Depth)

H (Height)

A

B

C(clearance for housing)

YFB010

RC1/2"

16.7

1.0

35.5

96

79

252

29

223

118

YFB020

RC3/4"

25.0

1.5

53.0

96

79

252

29

223

118

YFB030

RC3/4"

30.0

1.8

63.6

96

79

286

29

257

153

YFB040

RC1"

33.3

2.0

71.0

96

79

286

29

257

153

YFB060

RC1"

60.0

3.6

127.0

138

111

357

37

320

208

YFB070

RC1"

83.3

5.0

177.0

138

111

458

37

421

303

YFB080

RC1-1/2"

125.0

7.5

265.0

138

111

458

37

421

303

YFB090

RC2"

166.7

10.0

353.1

174

142

558

58

500

467

YFB100

RC2-1/2"

216.7

13.0

459.0

174

142

558

58

500

467

YFB110

RC2"

283.3

17.0

600.0

174

142

838

58

780

794

YFB120

RC2-1/2"

316.7

19.0

671.0

174

142

838

58

780

794

YFB130

RC3"

416.7

25.0

883.0

220

184

645

74

571

514

YFB140

RC4"

466.7

28.0

989.0

220

184

645

74

571

514

YFB150

RC3"

683.3

41.0

1448.0

220

184

902

74

828

764

YFB160

RC4"

800.0

48.0

1695.0

220

184

902

74

828

764

Technical requirements

Maximum operating pressure: 16 barg Maximum operating temperature: 80°C Minimum operating temperature:1.5°C

Pressure

Barg

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Psig

15

29

44

59

73

87

100

116

131

145

160

174

189

203

219

232

Correction factor

0.38

0.53

0.65

0.76

0.85

0.93

1.00

1.07

1.13

1.19

1.23

1.31

1.36

1.41

1.46

1.51

Success Cases Share

Related Keywords