Installation method of compressed air filter

-

$182.191-19 Piece/Pieces

-

$173.08≥20 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shenzhen, Guangzhou, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500pcs per day |

| Supply Ability: | 500PCS Per Days |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| HS Code: | 8421399090 |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou,Shanghai |

Installation method of compressed air filter

①Install and use within the specified working pressure and working temperature range, and install all levels of filters in the correct order according to the air inlet and outlet instructions or the direction indicated by the arrow, from coarse to fine installation. Avoid bypass as much as possible during installation. Because the oil in the air is bypassed to the downstream of the filter and then sticks to the inner wall of the pipeline, it is difficult to find effective means to remove it.

②The filter element should be replaced regularly. When replacing the filter element, use an Allen wrench to unscrew the four screws of the lower cover and take out the old filter element from below. Carefully record the replacement time. It is recommended that the working time z should not exceed 8000 hours.

③The discharge time of the auto drain is suitable for draining the liquid water, and the discharge interval is subject to the water content in the pipeline;

④Different grades of compressed air filters can be equipped with electronic drain valves or manual valves according to customer requirements.

| PF | AO | AA | AX | ACS | AR | AAR |

| As a primary filter, particles whose diameter more than 5μm can be remove,the maxi. residual oil content is negligible | High efficiency general protection, dust particles, water mist & oil mist whose diameter more than 1μm can be removed, the residual content of oil mist does not exceed 0.6mg/m³ (21ºC),1ppm(w). | High effiency oil remove filtration, dust particles, water mist and oil mist whose diameter more than 0.01μm can be removed, the residual content of oil mist does not exceed 0.01mg/m³(21ºC),0.01ppm(w) | Ultra-efficient filtration, dust particles, water mist&oil mist whose diameter more than 0.01μm can be removed, the residual content of oil mist does not exceed 0.001mg/m³(21ºC),0.001ppm(w) | Dust particles whose diameter more than 0.01μm, oil vapor &odor can be removed, the maxi. resident content of oil vapor does not exceed 0.003mg/m³(21ºC),0.003ppm(w) | Dust particles whose diameter more than 1μm can be removed | Dust particles whose diameter more than 0.01μm can be removed |

International test and measurement standard ISO12500

>ISO 12500 has made clear a general test and definition method for the compressed air filter manufacturers. The main performance

parameters are the air inlet oil content and particles size distribution of the solid particles.

>ISO12500-1 specifies the test requirements for the filtration performance of oil aerosol in the coalescing filter.

>ISO12500-2 specifies the test requirements of adsorption filters for the removal performance of steam adsorption.

>ISO12500-3 specifies the requirements for removal of particulate matter from solid pullutants.

Product are test with the international advanced testing equipment based on standard ISO12500, Which is equivalent to the standard ISO8573.1-2010 quality standard, and provide filter performance test report.

Filtration Grade

PF

AO

AA

AX

ACS

AR

AAR

Size of solid particles(ISO12500-3)

5μm

1μm

0.01μm

0.01μm

-

1μm

0.01μm

Filtration performance of solid particles(ISO12500-3)

-

99.999+%

99.999+%

99.999+%

99.999+%

99.999+%

99.999+%

Filtration performance of oil(ISO12500-1)

50%

80+%

99.9+%

99.99+%

-

-

-

Residual oil content(ISO12500-1)

5mg/m³

0.6mg/m³

<0.01mg/m³

<0.001mg/m³

<0.004mg/m³

-

-

Product Picture

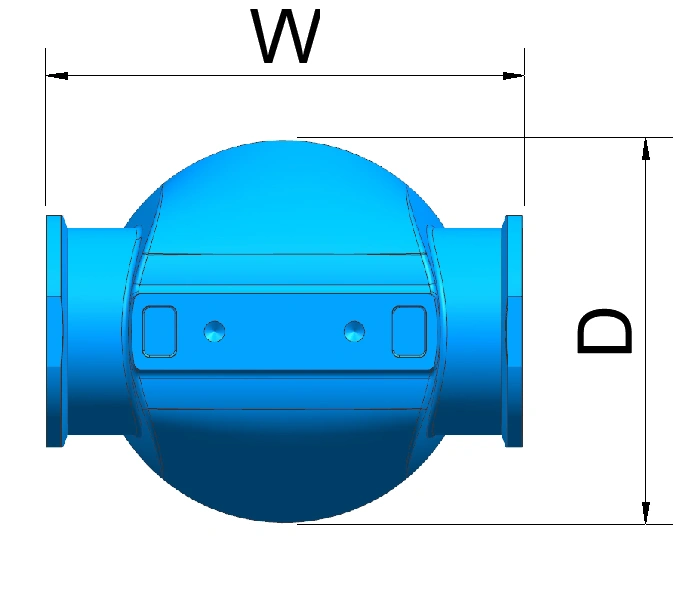

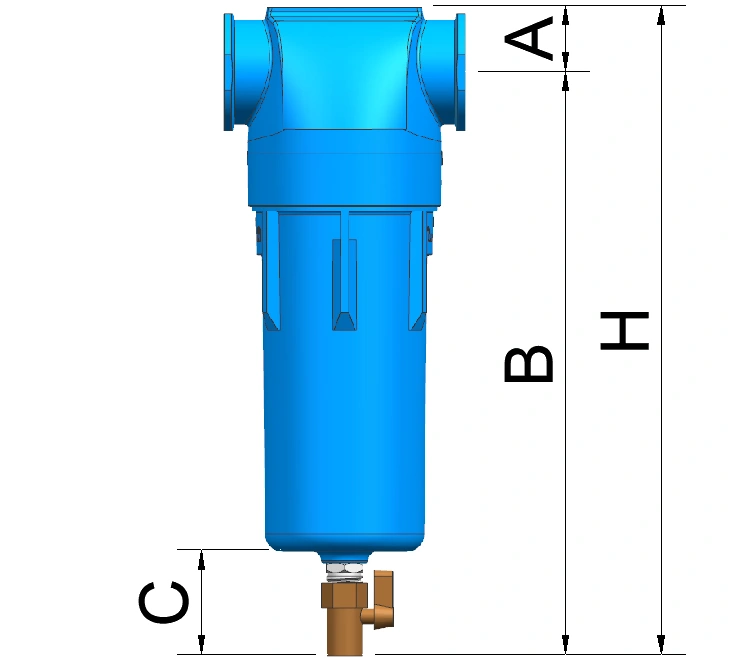

Technical Specification

| Model | Pipe size | Flow rates | Dimension (mm) | |||||||

| L/S | m³/min | scfm | W(Width) | D(Depth) | H (Height) | A | B | C(clearance for housing) | ||

| YFB010 | RC1/2" | 16.7 | 1.0 | 35.5 | 96 | 79 | 252 | 29 | 223 | 118 |

| YFB020 | RC3/4" | 25.0 | 1.5 | 53.0 | 96 | 79 | 252 | 29 | 223 | 118 |

| YFB030 | RC3/4" | 30.0 | 1.8 | 63.6 | 96 | 79 | 286 | 29 | 257 | 153 |

| YFB040 | RC1" | 33.3 | 2.0 | 71.0 | 96 | 79 | 286 | 29 | 257 | 153 |

| YFB060 | RC1" | 60.0 | 3.6 | 127.0 | 138 | 111 | 357 | 37 | 320 | 208 |

| YFB070 | RC1" | 83.3 | 5.0 | 177.0 | 138 | 111 | 458 | 37 | 421 | 303 |

| YFB080 | RC1-1/2" | 125.0 | 7.5 | 265.0 | 138 | 111 | 458 | 37 | 421 | 303 |

| YFB090 | RC2" | 166.7 | 10.0 | 353.1 | 174 | 142 | 558 | 58 | 500 | 467 |

| YFB100 | RC2-1/2" | 216.7 | 13.0 | 459.0 | 174 | 142 | 558 | 58 | 500 | 467 |

| YFB110 | RC2" | 283.3 | 17.0 | 600.0 | 174 | 142 | 838 | 58 | 780 | 794 |

| YFB120 | RC2-1/2" | 316.7 | 19.0 | 671.0 | 174 | 142 | 838 | 58 | 780 | 794 |

| YFB130 | RC3" | 416.7 | 25.0 | 883.0 | 220 | 184 | 645 | 74 | 571 | 514 |

| YFB140 | RC4" | 466.7 | 28.0 | 989.0 | 220 | 184 | 645 | 74 | 571 | 514 |

| YFB150 | RC3" | 683.3 | 41.0 | 1448.0 | 220 | 184 | 902 | 74 | 828 | 764 |

| YFB160 | RC4" | 800.0 | 48.0 | 1695.0 | 220 | 184 | 902 | 74 | 828 | 764 |

| Technical requirements | Maximum operating pressure: 16 barg Maximum operating temperature: 80°C Minimum operating temperature:1.5°C | |||||||||

| Pressure | Barg | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Psig | 15 | 29 | 44 | 59 | 73 | 87 | 100 | 116 | 131 | 145 | 160 | 174 | 189 | 203 | 219 | 232 | |

| Correction factor | 0.38 | 0.53 | 0.65 | 0.76 | 0.85 | 0.93 | 1.00 | 1.07 | 1.13 | 1.19 | 1.23 | 1.31 | 1.36 | 1.41 | 1.46 | 1.51 | |

YUKA Package

YUKA service

a. Providing professional consultation, technical support and special solutions

b. Providing timely feedback on complaints

c. Providing perfect after sales service and warranty

Q:Why choose us?

a. Over 20 years' practical experiences in R&D and manufacturing Compressed air treatment;

b. Founder of Compressed Air Nation Standard GB/T30475.1-2013 and GB/T30475.2-2013;

c. ISO 9001:2015, CE and product follow ISO8573-1;

d. With Germany Imported high efficiency filtration Test Instrument;

e.All goods had been 100% test before dispatched.

FAQ

Q1. What kind of your company is it?

We're the manufacturer integrated with R&D, production and sales.

Q2. How about your technical conditions and production capability?

Complete process documents and equipment, mass production.

Q3. What is the delivery time?

Delivery time depends on the order quantity, normally is 3-5 working days after 30% payment.

Q4. Do you have a warranty?

Yes, for filter, it is 1 year normally.

Q5. Can you supply customized product?

Yes, we have a professional technical team to provide you with the best solution and complete production processes and control to provide you with satisfied product.

Related Keywords