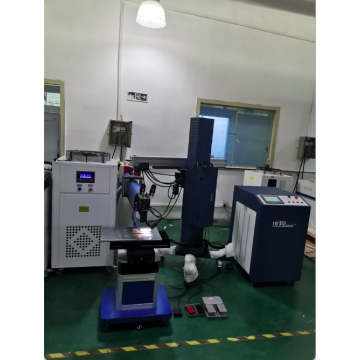

Robot laser welding machine:

-

$25000.00≥10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Transportation:

- Ocean, Land, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Express |

Robot laser welding machine:

Product Description:

It has high aspect ratio, small weld width, small heat affected zone and fast welding speed.

The welding seam is smooth and beautiful, and there is no need for treatment or simple treatment process after welding

The welding seam has high quality and no blowhole, which can reduce and optimize the impurities in the base metal. The microstructure can be refined after welding. The strength and toughness of the weld seam are at least equal to or even higher than that of the base metal

Robot arm generally refers to all kinds of electronic control machines and tools with elastic programming movement, which can replace human work. In industry, the most common multi degree of freedom arm is connected by multiple joints. The arm is commonly used for picking, assembling and classifying. Its advantages are fast speed and light weight. High degree of freedom, it can be widely used in spraying, welding, taking and placing, grinding and other applications, and the cost is relatively expensive.

In the trend of automation, machine replacement has become an irresistible trend, and the robot industry is facing unprecedented development opportunities.

What matters is the "end point", so the coordinate value of XYZ changes. When the end of the arm moves in a certain direction in a straight line, the joints of each axis will calculate the angle of rotation to match.

Bearing, when the starting point moves to the end point, it can be seen that the rotation relationship between the joints will change, which is to protect the end point from going straight in the XYZ direction.

When operating the arm, the running speed of the arm is affected by "motion parameters", "speed command" and "magnification".

The speed of arm movement depends on the mode

In the "automatic" mode, the arm moves according to the program command, and the running speed of the motion command is adjusted through the "speed command".

Applicable materials:

It is mainly used for welding stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, aluminum zinc plate and other metal welding.

Application range

The manipulator usually needs a tray as the place to pick up the material or place the finished product when taking and placing the material

The tray may be fixed, movable or manually placed, so the movement of the robot arm is usually more complex, and each time it reaches the position of the tray

Different settings may also be required. In this function, the user only needs to understand the point teaching of the material tray (like the concept of reference point setting)

The parameter setting and action editing (M code and subroutine call) of the material tray, and the change of the material tray when the material tray is empty or full

In order to achieve the purpose of easy operation, it is unnecessary to know the details of the movement

Processed products:

Technical parameters:

model

UK-HJLX-SC1000W

Laser wavelength

1064nm

Maximum laser output power

1000W

Maximum laser pulse energy

100J/20ms

Maximum welding depth

≤3mm

pulse width

01-20ms

Pulse frequency

0-200Hz

Repeat positioning accuracy

±0.02mm

spot size

0.2mm-2.0mm

Aiming and positioning mode

Red light indication (CCD optional)

Electricity demand

Three phase 380V ± 15% 50 Hz 25A

Main engine power

16KW

Control system

PFCs laser power real time feedback system

Cooling mode

Internal circulating water

Manipulator stroke

1.5 m

Related Keywords