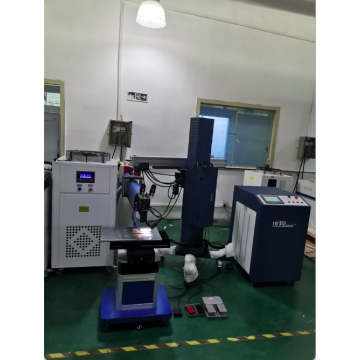

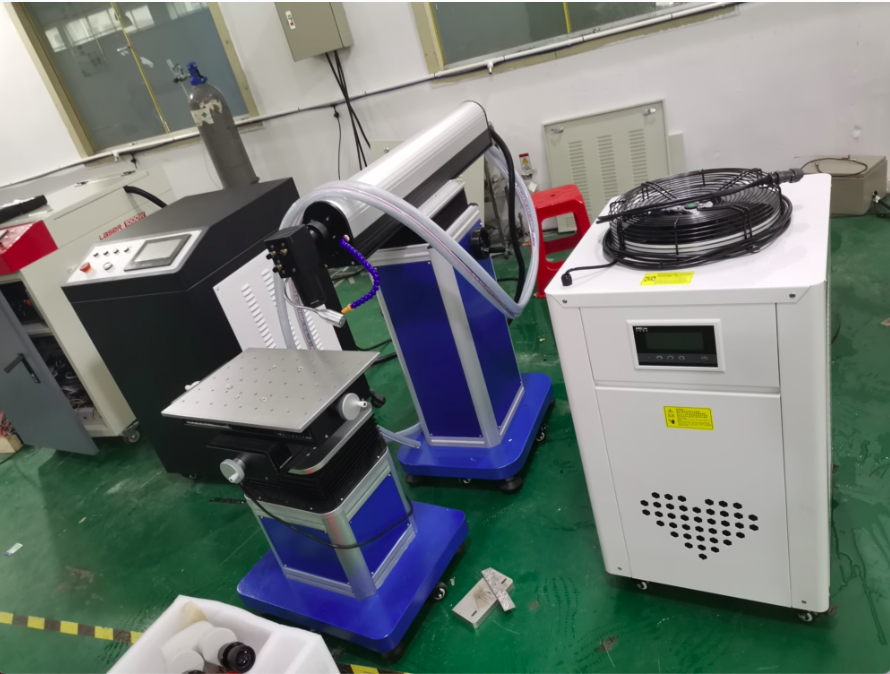

Boom type die laser welding machine

-

$15000.00≥4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Transportation:

- Ocean, Land, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Express |

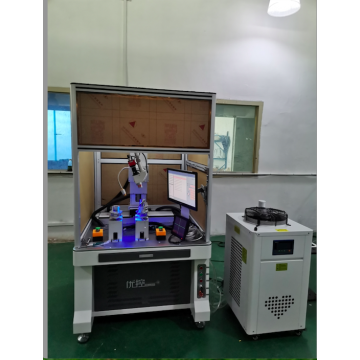

Jewelry laser spot welder (integrated)

Excellent control laser has developed a machine integrating water tank and machine, which saves the utilization position of space. It is mainly used for spot welding sand holes, patching holes, repairing seam lines, spot welding sand holes and claw and foot parts of inlaid parts of gold and silver jewelry. The size of welding spot can be adjusted freely during welding; Small heat affected zone; Fine and beautiful solder joints without excessive post weld treatment; Precise positioning, no damage to the surrounding inlaid jewelry during welding.

Jewelry laser spot welder is a water-cooled integrated laser welding system developed by optimal control laser for the needs of jewelry industry. The system is mainly composed of laser, power supply and control, chiller, light guide and focusing, binocular stereoscopic microscopic observation, compact structure and small volume. The micro coordinate indication coaxial with the laser beam makes it easy to locate the workpiece without special fixture. Laser power, pulse frequency and pulse width can be preset and changed through the control panel. It is equipped with high-speed electronic filter protection device to protect the operator's eyes from laser damage, alleviate the operator's glasses fatigue and improve work efficiency. A high-definition CCD monitoring system can be added according to requirements. It is mainly used for spot welding sand holes, patching holes, repairing seam lines, spot welding sand holes and claw and foot parts of inlaid parts of gold and silver jewelry. The size of welding spot can be adjusted freely during welding; Small heat affected zone; Fine and beautiful solder joints without excessive post weld treatment; Precise positioning, no damage to the surrounding inlaid jewelry during welding

characteristic:

1. The high-performance laser power supply developed by our company makes the single pulse energy high, the power low, the heat effect very low, and the welding is not hot.

2. Automatic shading system is adopted to eliminate the damage to eyes during working hours. Humanized design, in line with ergonomics, long-time work without fatigue.

3. There is no need to fill solder, fast welding speed, high quality, reliable contact, small workpiece deformation, small heat affected zone, beautiful forming, pollution-free solder joint, high efficiency and environmental protection.

4. Ceramic laser cavity and the R & D products of international well-known manufacturers ensure the high reliability and high performance of the equipment. It has 24-hour continuous working capacity, stable working performance and maintenance free within 10000 hours.

5. The unique YAG crystal cooling mode improves the beam quality and the service life of xenon lamp, and reduces the service cost.

6. Energy, pulse width, frequency and spot size can be adjusted in a large range to achieve a variety of welding effects. The parameters are adjusted by the control rod in the closed cavity, which is simple and efficient.

Application fields:

Jewelry laser welding machine can weld various metal materials and their alloys such as K gold, platinum, titanium, silver, copper, stainless steel and aluminum, as well as precision welding of various jewelry and micro parts. It is suitable for many industries and fields such as electronics, communication, hardware, clocks and watches, medical devices, aluminum alloy dentures, instruments, machining, automobile and so on.

Technical parameters:

Model dy-esw200 dy-esw400 dy-esw600

Maximum laser power 200W 400W 600W

Laser wavelength 1064nm 1064nm 1064nm

Welding frequency ≤ 100Hz ≤ 100Hz ≤ 100Hz

Pulse width 0.1-20ms 0.1-20ms 0.1-20ms

Laser welding depth ≤ 2.0mm ≤ 3.0mm ≤ 5.0mm

Spot diameter adjustable 0.1-2.0mm 0.1-2.0mm 0.1-3.0mm

Power demand AC220V / 50Hz single-phase AC380V / 50Hz three-phase AC380V / 50Hz three-phase

Power consumption of the whole machine ≤ 7KW ≤ 13kw ≤ 18kw

Control system microcomputer program control

Cooling system external / internal water cooling optional

Related Keywords