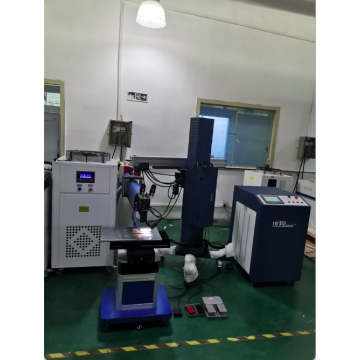

Laser automatic laser welding machine

-

$18000.00≥4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Air,Express |

Product Description

Product Description

Characteristics and advantages of automatic laser welding machine

The full-automatic laser welding machine irradiates the laser beam with high energy density on two parts of materials to make the local heat melt, and then cool and solidify into one. Compared with the traditional welding process, laser welding has the following advantages:

A. No contact processing, no external force on welded parts.

B. The laser energy is highly concentrated, the thermal effect is small, and the thermal deformation is small.

C. It can weld metals with high melting point, difficult to melt and difficult to weld, such as titanium alloy, aluminum alloy, etc. Welding between some dissimilar materials can be realized.

D. The welding process has no pollution to the environment. It can be welded directly in the air, and the process is simple.

E. Small welding spot, narrow weld, neat and beautiful, no treatment or simple treatment process after welding. The weld has uniform structure, few pores and few defects, which can reduce and optimize the miscellaneous welding of parent material

The mechanical strength of the joint is often higher than that of the base metal. The mechanical properties, corrosion resistance and electromagnetic properties of laser welding are better than those of conventional welding methods.

F. The laser can be accurately controlled, the focusing light spot is small, the positioning can be high-precision, and the precision machining can be realized.

G. It is easy to cooperate with computer numerical control system or manipulator and robot to realize automatic welding and improve production efficiency.

The full-automatic laser welding machine irradiates the laser beam with high energy density on two parts of materials to make the local heat melt, and then cool and solidify into one. Compared with the traditional welding process, laser welding has the following advantages:

A. No contact processing, no external force on welded parts.

B. The laser energy is highly concentrated, the thermal effect is small, and the thermal deformation is small.

C. It can weld metals with high melting point, difficult to melt and difficult to weld, such as titanium alloy, aluminum alloy, etc. Welding between some dissimilar materials can be realized.

D. The welding process has no pollution to the environment. It can be welded directly in the air, and the process is simple.

E. Small welding spot, narrow weld, neat and beautiful, no treatment or simple treatment process after welding. The weld has uniform structure, few pores and few defects, which can reduce and optimize the miscellaneous welding of parent material

The mechanical strength of the joint is often higher than that of the base metal. The mechanical properties, corrosion resistance and electromagnetic properties of laser welding are better than those of conventional welding methods.

F. The laser can be accurately controlled, the focusing light spot is small, the positioning can be high-precision, and the precision machining can be realized.

G. It is easy to cooperate with computer numerical control system or manipulator and robot to realize automatic welding and improve production efficiency.

Related Keywords

Related Keywords