Laser welding machine in instrument industry

-

$8000.00≥4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Min. Order:

- 4000 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Air,Express |

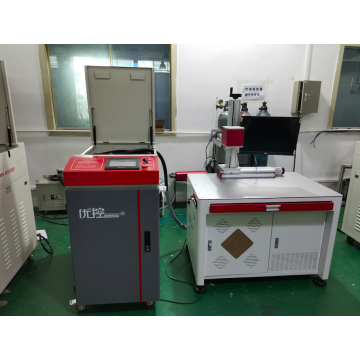

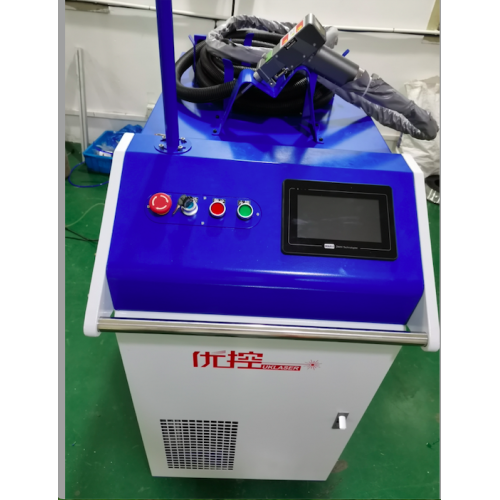

Precision instrument optical fiber laser welding machine is a high-end and new welding method, which is generally composed of "welding host" and "welding workbench". The laser beam is coupled to the optical fiber. After long-distance transmission, it is processed into parallel light to focus on the workpiece for continuous welding. Due to the continuity of light output, the welding effect is firmer and the weld is more fine and beautiful.

Optical fiber laser welding machine for precision instruments and meters has the common welding function. Besides the effects of fast welding speed, small deformation and no bubbles, the minimum spot of the focused optical fiber laser beam can reach 10 microns, so the welding spot is very small. And because it is a continuous wave laser, it can meet the high power density of batch and continuous welding. Galvanometer + coaxial vision positioning + three-axis electric platform, integrating large format and high precision. The electro-optic conversion rate is as high as 30%, and the power consumption of the whole machine is low. Module design, easy to integrate into the automatic production line.

Low maintenance cost

Optical fiber laser welding machine for precision instruments and meters has large weld depth ratio, small specific energy, small heat affected zone and small deformation of weldment. It is especially suitable for the welding of precision and heat sensitive parts, and can often avoid post welding correction and processing technology. The maintenance cost is low, and there are few failures after purchase, which can greatly improve the production efficiency. Energy saving and environmental protection, the smoke generated in the welding process is very little, basically will not affect people's health.

High efficiency

The optical fiber laser welding machine for precision instruments has high degree of automation and simple welding process. The non-contact operation method can meet the requirements of cleaning and environmental protection. Using fiber laser welding machine to process workpiece can improve work efficiency. The finished workpiece has beautiful appearance, small weld, large welding depth and high welding quality.

Related Keywords