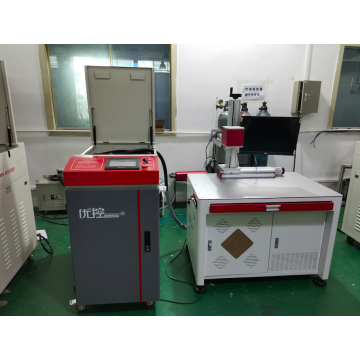

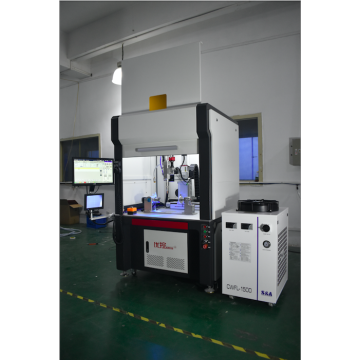

fibre laser welding machine

-

$8000.00≥2400 Set/Sets

- Min. Order:

- 2400 Set/Sets

- Min. Order:

- 2400 Set/Sets

- Transportation:

- Ocean, Land, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP |

| Transportation: | Ocean,Land,Express |

Characteristics of fiber laser marking machine:

1. It can process a variety of metal and non-metal materials, especially for high hardness, high melting point and brittle materials;

2. It belongs to non-contact processing, no damage to products, no tool wear, good marking quality;

3. The laser beam is thin, the material consumption is small, and the heat affected zone is small;

4. The processing efficiency is high, which is 2-3 times of the traditional laser marking machine;

5. Long service life, using laser diode as pump source, the average working time can reach 100000 hours;

6. The cost is low, the electro-optic conversion efficiency is as high as 30%, and the power consumption of the whole machine is less than 500W, which is 1 / 10 of that of the solid-state laser marking machine with equal pump source, greatly saving energy consumption;

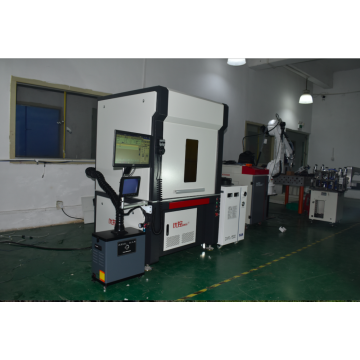

Professional pipe cutting programming software is one of the core technologies of CNC pipe cutting machine to achieve "full-time cutting, efficient cutting", which is the fundamental guarantee to effectively save materials and improve cutting efficiency.

The capacitive fiber laser cutting head has the advantages of high induction precision, sensitive response and the most stable and reliable performance.

The unique trusteeship device keeps contact with the surface of the pipe when the pipe is fed and rotated. The support force is set according to the pipe specification to ensure effective support, prevent the pipe from sagging, reduce the axis swing when the pipe rotates, and improve the processing accuracy.

Automatic whole bundle feeding function (optional), reduce the number of operators and improve the processing efficiency at the same time.

|

model |

UK-HJLX-SC500W |

UK-HJLX-SC1000W |

UK-HJLX-SC1500W |

|

|

500w |

1000w |

1500w |

|

Laser wavelength

|

1070±5 nm |

1070±5 nm |

1070±5 nm |

|

Operation mode

|

Continuous / modulation |

Continuous / modulation |

Continuous / modulation |

|

Output welding joint type |

Hand held swinging head |

Hand held swinging head

|

Hand held swinging head |

|

Output power stability |

<3% |

<3% |

<3% |

|

Power regulation range |

10~100% |

10~100% |

10~100% |

|

Weld penetration

|

0.5~2.0mm |

0.5~2.0mm |

0.5~2.0mm |

|

Spot width

|

0.2-3mm |

0.2-3mm |

0.2-3mm |

|

Cooling mode

|

Built in water cooling |

Built in water cooling |

Built in water cooling |

|

Fiber line length

|

Standard 10 meters, Max15 meters |

Standard 10 meters, Max15 meters |

Standard 10 meters, Max15 meters |

|

Blowing protection |

Argon, nitrogen |

Argon, nitrogen |

Argon, nitrogen

|

|

Electricity demand

|

AC220v/50Hz |

AC220v/380v/50Hz |

AC380v/50Hz |

|

Equipment power

|

3.5 Kw |

4.5 Kw |

5.5 Kw |

|

area covered

|

1*1.6m |

1*1.6m |

1*1.6m |

|

Overall weight |

180 Kg |

200 Kg |

200 Kg |

|

working temperature |

0~40°C |

0~40°C |

0~40°C |

|

Working humidity |

10~75% |

10~75% |

10~75% |

|

Environmental requirements

|

No vibration, no interference source, keep ventilation |

No vibration, no interference source, keep ventilation |

No vibration, no interference source, keep ventilation |

|

Consumables

|

Purified water, argon

|

Purified water, argon

|

Purified water, argon

|

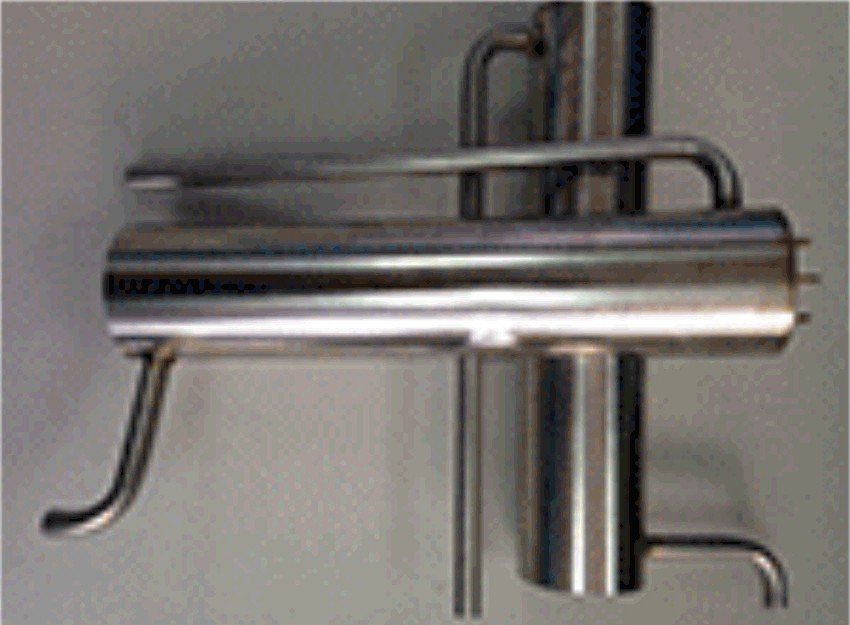

Working drawing

Related Keywords