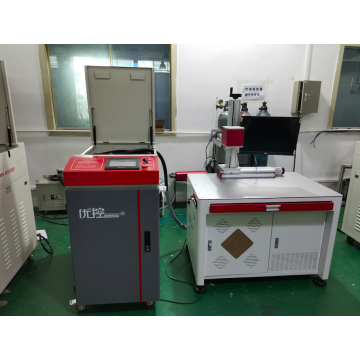

Hand held stainless steel laser welding machine

-

$8800.00≥4800 Set/Sets

- Min. Order:

- 4800 Set/Sets

- Min. Order:

- 4800 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Air,Express |

The laser welding machine for stainless steel uses the 1064nm pulse laser generated by the laser to radiate the surface of the workpiece after beam expansion, reflection and focusing. The surface heat is guided to the internal diffusion through heat transfer. The parameters such as laser pulse width, energy, peak power and repetition frequency are precisely controlled by digitization to make the workpiece melt and form a specific molten pool, So as to realize the laser welding of the processed parts and complete the precision welding which can not be realized by traditional technology.

The laser welding machine for stainless steel Product introduction:

1. High speed, large depth and small deformation.

2. It can be welded at room temperature or under special conditions, and the laser welding equipment is simple. For example, when a laser passes through an electromagnetic field, the beam will not shift; Laser welding can be carried out in vacuum, air and some kind of gas environment, and can be carried out through glass or materials transparent to the beam.

3. It can weld refractory materials, such as titanium, and can weld dissimilar materials with good effect.

4. After laser focusing, the power density is high. When high power devices are welded, the aspect ratio can reach 5:1, and the maximum can reach 10:1.

5. Micro welding. It can be used in the assembly and welding of micro and small workpieces in mass automatic production.

6. It can be used to weld inaccessible parts. It has great flexibility to carry out non-contact long-distance welding. Especially in recent years, optical fiber transmission technology has been used in YAG laser processing technology, which makes laser welding more widely promoted and applied.

7. Laser beam is easy to realize beam splitting according to time and space. It can process multiple beams at the same time and in multiple positions, which provides conditions for more precise welding

The laser welding machine for stainless steel Scope of application:

Suitable for stainless steel, aluminum, copper, gold, silver, chromium, nickel, titanium and other metals or alloys, can also be used for a variety of dissimilar materials welding. Such as copper brass, titanium gold, titanium molybdenum, nickel copper and so on.

Related Keywords