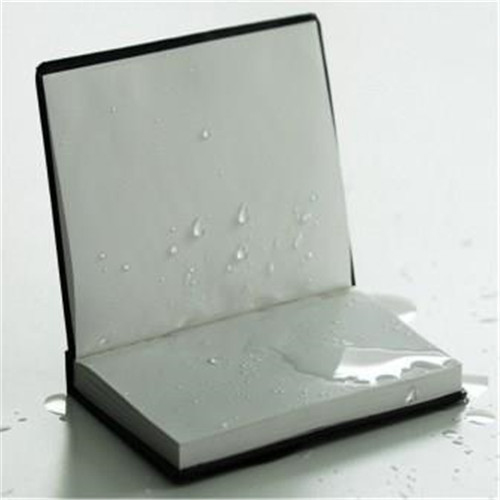

environmental paper synthetic paper stone paper

Your message must be between 20 to 2000 characters

Contact Nowenvironmental paper synthetic paper stone paper

The Features of (RBD) Rich Mineral Board Double Coated Stone PaperFor plastic/ paper board applications

200-400 mircrons thick

60% calcium carbonate + 40%PE

Type

Thickness

Density

Base Weight

Opacity

Applications

um

g/cm3

(g/m2)

(micrometers)

(RBD) Rich Mineral

Board Double Coated

250

1.5

375

>90%

Paper bags,Kid's books,Calendar, leaflets,

brochures, packaging,boxes, gift boxes,

Album of paintings,Displays,

outdoor applications,

300

450

>90%

350

525

>90%

400

600

>90%

1. One ton stone paper can save 20 trees.

2. One ton stone papercan save 280Kw /H electric energy.

3. One ton stone paper can save 7480 gallons clean water.

4. The stone paper production area was only 1/10 of the traditional fiber factory.

5. Stone paper production need only circulating cooling water, the traditional fiber paper produces a large amount of wastewater.

HOW TO OFFSET PRINT RICH MINERAL BOARD

Rich mineral paper/ board can be printed through most printing methods, which include offset, gravure, flexography, screen and rotary. Rich mineral paper/ board has advantages of pulp and synthetic paper. It can be easily printed by using common printing machines and methods. Moreover, it has water resistant properties like the synthetic paper. We recommend the following when printing on rich mineral paper/ board (RPD and RBD). Please note the following is only a guide. Settings can still vary between different printers and operators.

- Regular ink and soy ink are adequate for rich mineral paper/ board print.

- Printing speed is approximately 7500 ~ 8000 sheets per hour for dark / solid color, more than 9000 sheets for lighter colors.

- Water feed is [Set 21 and Ratio 115].

- Ink feed is [Set 40 and Ratio 116].

- Drying powder is level 4~6, depending on the artwork.

- RPD and RBD's surface immediately dries after print. For rich mineral paper/ board (RPD & RBD) to fully dry and ready for further prints or processes please allow approximately 1 hour after light color prints or 6 hours after dark color prints.

- When stacking printed paper, please place separating plates as required.

- To minimize static, please maintain at least 40% relative humidity. Anti-static equipment such as ionizing air units at the feeder and/or delivery is preferred but not essential.

- Please trim 4 sides of the paper where higher printing and conversion precisions are required.

Related Keywords