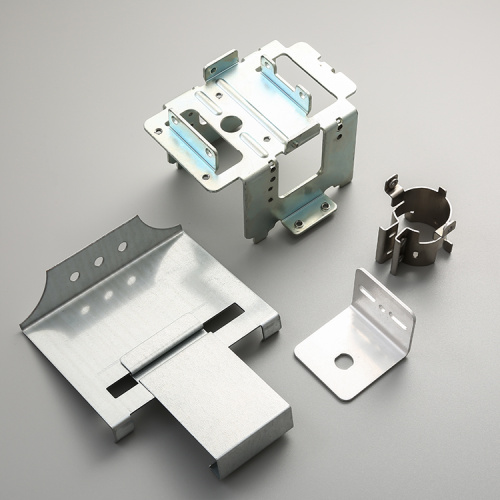

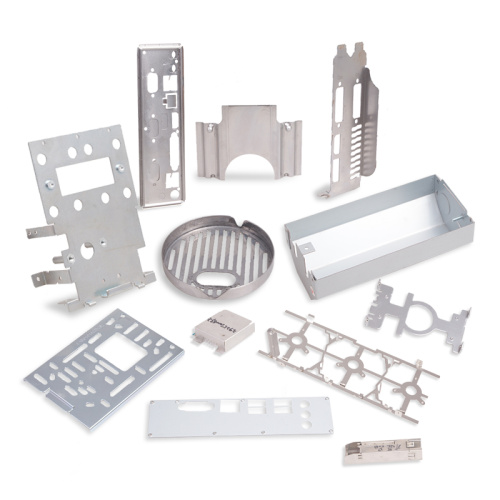

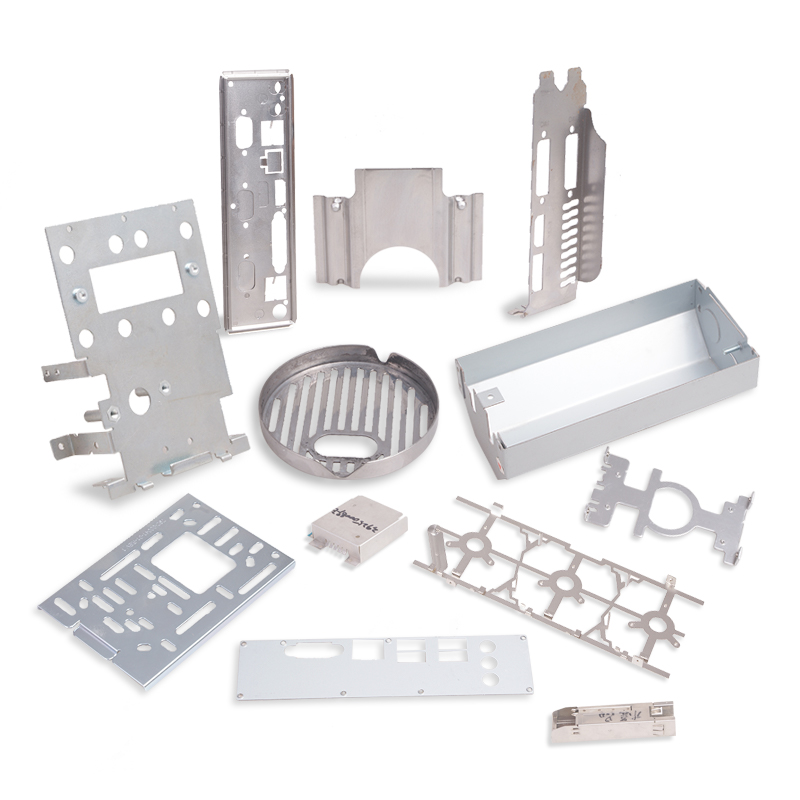

Custom Sheet Metal Fabrication Product

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Many industrial fabrication processes on metallic structures generate a great deal of work place noise. For example, riveting and chiseling on light-weight, stiff aerospace structures such as fusalage components and flight surfaces subject the workpiece to repeated impacts and consequent noise generation. Many such structures may be lightly damped. Many damping treatments are targeted toward permanent installation on a structure, but if the treatments are considered to be removable, one has design freedoms including placement on a structure, as well as mass and damping means, that might not otherwise exist if the treatment had to remain in place. A shot-mass or particle-impact damper configured in an elastic, cellular array is shown to provide high loss factors and mass loading, which, along with ease of placement and removal, may provide significant reduction in component vibration during fabrication and consequent reduction in noise in the work place. The concept applied to an example aircraft panel when subjected to riveting operations yields more than 10 dB of noise reduction.

Sheet metal fabricators first convert CAD and drawing data into machine code. A laser cutting, waterjet, or plasma cutting machine will then precisely remove sheet metal material. The raw material is formed into angular bends and features using brakes, punches, and dies. If any assembly or post-processing is required, our sheet metal manufacturers will weld, add inserts, or finish the part.

The efficiency and high precision of metal fabrication, coupled with Bergek’s variety of materials, range of sheet metal fabricators, and post-processing options means you can get parts for any application. Sheet metal applications include aerospace, defense, automotive, energy, industrial, medical, dental, and consumer products.

Product Details:

According to your drawings (size, material, thickness, processing content, required technology, etc.)

Material: carbon steel, SPCC, SGCC, stainless steel, aluminum, brass, copper, etc

Processing: Laser cutting, precision stamping, bending, CNC punching, grinding, riveting, drilling, welding, and so on

Surface treatment: drawing, polishing, anodizing, powder coating, electroplating, screen printing, sandblasting, etc

Tolerance: ±0.1mm, 100%QC before delivery, can provide quality control table

Size: Accept custom size.

Colors: white, blank, silver, red, gray, Pantone, RAL, etc

Drawing format: DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, draft.

Price terms: EXW, FOB, CIF, DDP, etc

Payment term: Sample: 100% payment before production

Mass production :(50% in advance as deposit, balance before delivery)

Certificate: ISO9001:2015 / SGS

FAQ:

Q1: Are you a factory or a trading company?

A: We are a factory, so we can offer you competitive prices.

Q2: What kind of services do you offer?

A: OEM sheet metal processing, CNC processing, stamping tool manufacturing, etc.

Q3: What information is required for a quotation?

A: In order to quote for you earlier, please provide us with the following information at the time of inquiry.

1. Detailed drawings (STEP,CAD,SOLID Works,DXF,PDF)

2. Material requirements (SUS,SPCC,AL,SECC,SGCC)

3.Surface treatment(powder coating,planting,sand blasting,polishing,oxidization,brushing,etc)

4. Quantity (per order/month/year)

5. Any special requirements or requirements, such as packaging, delivery, labeling, etc.

Q4: What if there are no drawings?

A: Please send your sample to our factory, then we can copy or provide you with a better solution, please send us pictures or sketches with dimensions (thickness, length, height, width), if the order is placed, CAD or 3D files will be made for you.

Why us?

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

click request quotation

Related Keywords