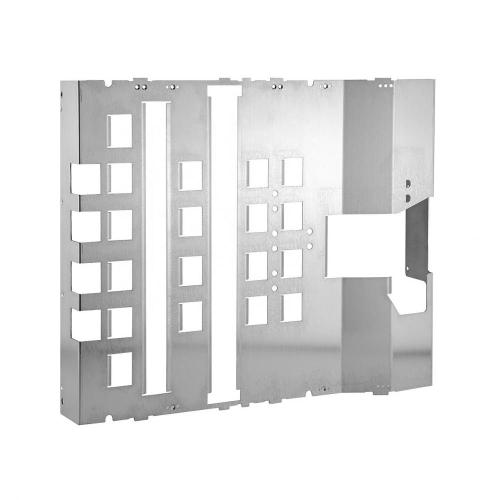

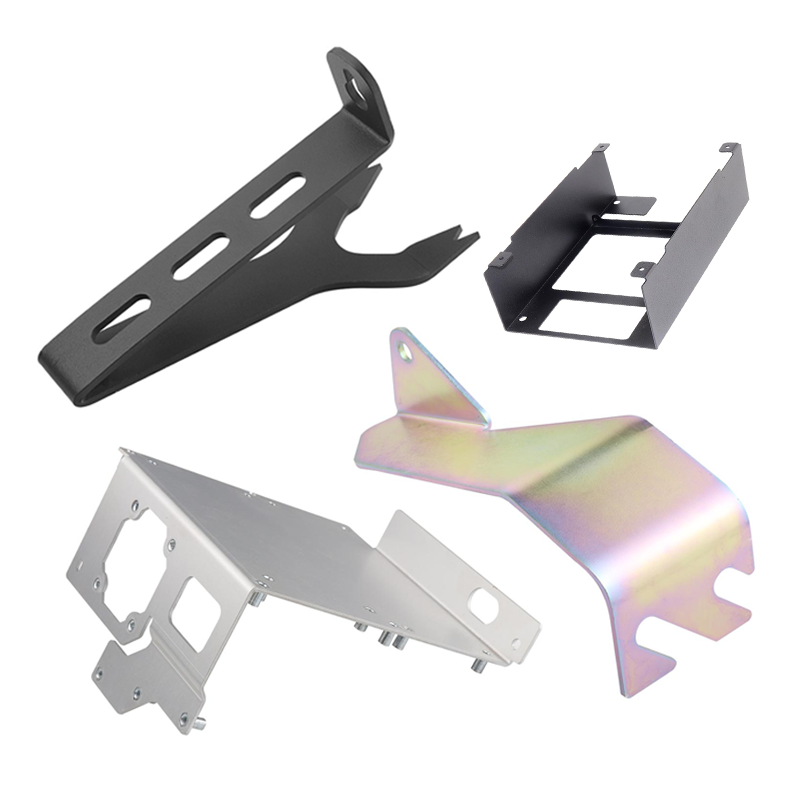

Hot selling sheet metal fabrication custom prototype service

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high precision and durability, especially for end-use applications like chassis, enclosures, and brackets.

Bergek’s sheet metal forming services provide a fast and cost-effective solution for any parts that need to be made from 3D CAD files or engineering drawings. Bergek offers a range of sheet metal materials, including aluminum, copper, steel, and stainless steel, as well as assembly services like installing PEM inserts, welding, and finishing services. With a network of domestic and overseas fabricators, Bergek can supply any quantity of parts from low-volume, high-mix prototypes to high-volume production runs. Bergek offers competitive sheet metal prices for low volume prototypes and cost savings for high volume production runs.

Sheet stock is procured in a flat state and cut then formed into its final state through a series of progressive steps. For a typical sheet metal project, the first step is equivalent to sheet cutting, where a shear, laser, waterjet, plasma, or punch press is used to create the internal holes and edge features of the part. This process is also known as blanking.

Once the blank is produced, the next step is forming using various tools, but most commonly some sort of brake. A brake press can be manual or automated and uses die inserts to create a desired angular bend, forming the two-dimensional sheet into a three-dimensional object. Sheet metal forming can bend the part in multiple directions, creating simple parts such as brackets up to highly complex geometries which may require custom die tools. Once the tools are in place, making subsequent sheet parts in production is very cost-effective. This makes sheet metal forming and fabricating ideal for low to high volume production.

Product Details:

According to your drawings (size, material, thickness, processing content, required technology, etc.)

Material: carbon steel, SPCC, SGCC, stainless steel, aluminum, brass, copper, etc

Processing: Laser cutting, precision stamping, bending, CNC punching, grinding, riveting, drilling, welding, and so on

Surface treatment: drawing, polishing, anodizing, powder coating, electroplating, screen printing, sandblasting, etc

Tolerance: ±0.1mm, 100%QC before delivery, can provide quality control table

Size: Accept custom size.

Colors: white, blank, silver, red, gray, Pantone, RAL, etc

Drawing format: DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, draft.

Price terms: EXW, FOB, CIF, DDP, etc

Payment term: Sample: 100% payment before production

Mass production :(50% in advance as deposit, balance before delivery)

Certificate: ISO9001:2015 / SGS

FAQ:

Q1: Are you a factory or a trading company?

A: We are a factory, so we can offer you competitive prices.

Q2: What kind of services do you offer?

A: OEM sheet metal processing, CNC processing, stamping tool manufacturing, etc.

Q3: What information is required for a quotation?

A: In order to quote for you earlier, please provide us with the following information at the time of inquiry.

1. Detailed drawings (STEP,CAD,SOLID Works,DXF,PDF)

2. Material requirements (SUS,SPCC,AL,SECC,SGCC)

3.Surface treatment(powder coating,planting,sand blasting,polishing,oxidization,brushing,etc)

4. Quantity (per order/month/year)

5. Any special requirements or requirements, such as packaging, delivery, labeling, etc.

Q4: What if there are no drawings?

A: Please send your sample to our factory, then we can copy or provide you with a better solution, please send us pictures or sketches with dimensions (thickness, length, height, width), if the order is placed, CAD or 3D files will be made for you.

Why us?

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

click request quotation

Related Keywords