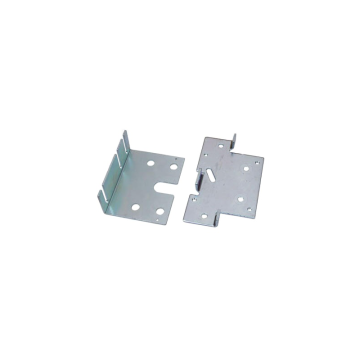

Steel panel Bending Fabrication

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Sheet metal processing technology - surface treatment

Sheet metal surface treatment can play an anti-corrosion protection and decoration. Common surface treatment of sheet metal are: powder spraying, electrogalvanizing, hot dip zinc, surface oxidation, surface drawing, screen printing and so on.

Remove oil, rust, and welding slag from the sheet metal before surface treatment.

Powder spraying:

Sheet metal surface spray has two kinds of liquid and powder paint, we commonly use powder paint. By spraying powder, electrostatic adsorption, high-temperature baking and other ways, spray a layer of various colors on the surface of the sheet metal to beautify the appearance and increase the corrosion resistance of the material. It is a common surface treatment.

2. Electric galvanizing, hot dipping zinc

Galvanized sheet metal surface is a common surface anti-corrosion treatment method, and can play a certain role in beautifying the appearance. Galvanizing can be divided into electric galvanizing and hot dip zinc.

Electric galvanized appearance is bright and smooth, galvanized layer is thin, more commonly used.

Hot dip zinc galvanized layer is thicker, and can produce iron zinc alloy layer, corrosion resistance is stronger than electric galvanized.

3. Surface oxidation:

Here mainly introduces the surface anodizing of aluminum and aluminum alloy.

The surface of aluminum and aluminum alloy can be oxidized into various colors by anodic oxidation, which plays a protective role as well as a good decorative role. At the same time, anodic oxide film can be produced on the surface of the material, anodic oxide film has high hardness and wear resistance, and has good electrical insulation and insulation.

4. Surface drawing:

The material is placed between the upper and lower roller wheels of the wire drawing machine, the roller is attached with sand belt, driven by the motor, so that the material passes through the upper and lower sand belt, and pulls out traces on the surface of the material. According to the different sand belt, the trace thickness is not the same, the main function is to beautify the appearance. It is generally aluminum material to consider the surface treatment with wire.

5. Screen printing

The process of screen printing on the surface of materials, generally there are two ways of screen printing and pad printing, screen printing plate is mainly used in the general plane, but if there is a deep pit, you need to use pad printing.

Screen printing must have a screen printing mold.

Why us?

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

click request quotation

Related Keywords