Self Reversing Screw OEM Factory Custom - alibaba

-

$6.50≥99 Piece/Pieces

- Min. Order:

- 99 Piece/Pieces

- Min. Order:

- 99 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IS09001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

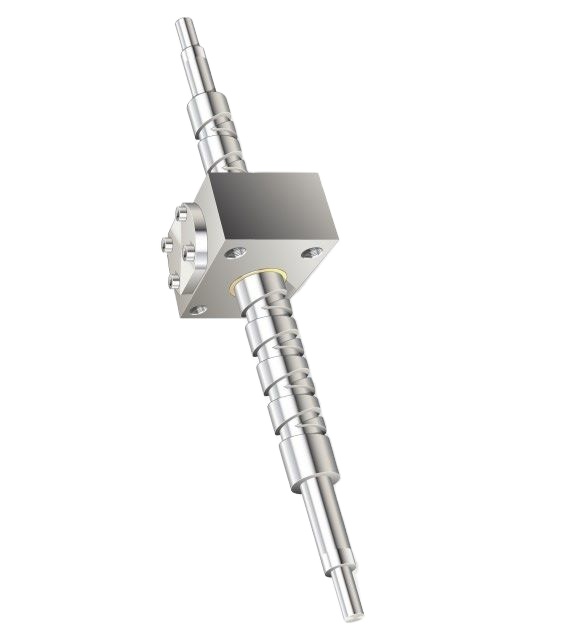

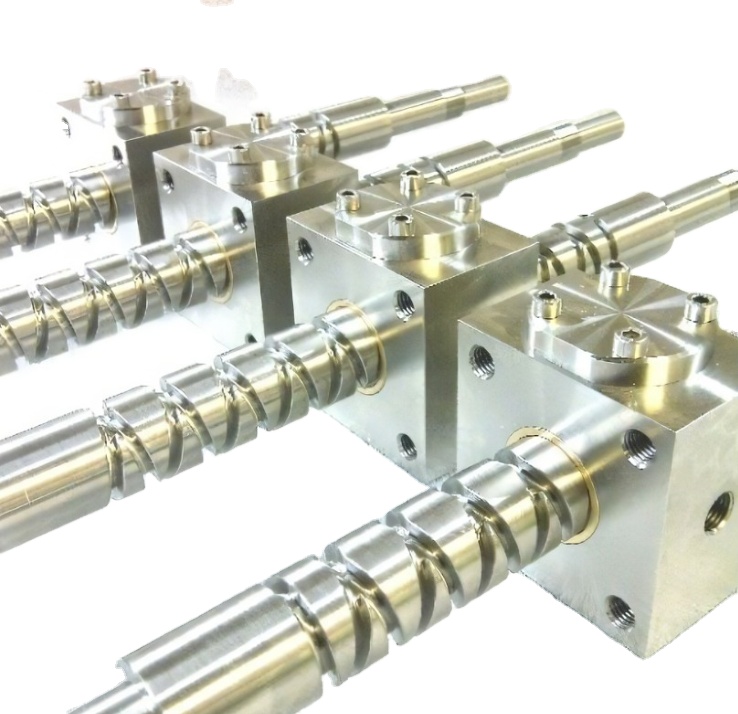

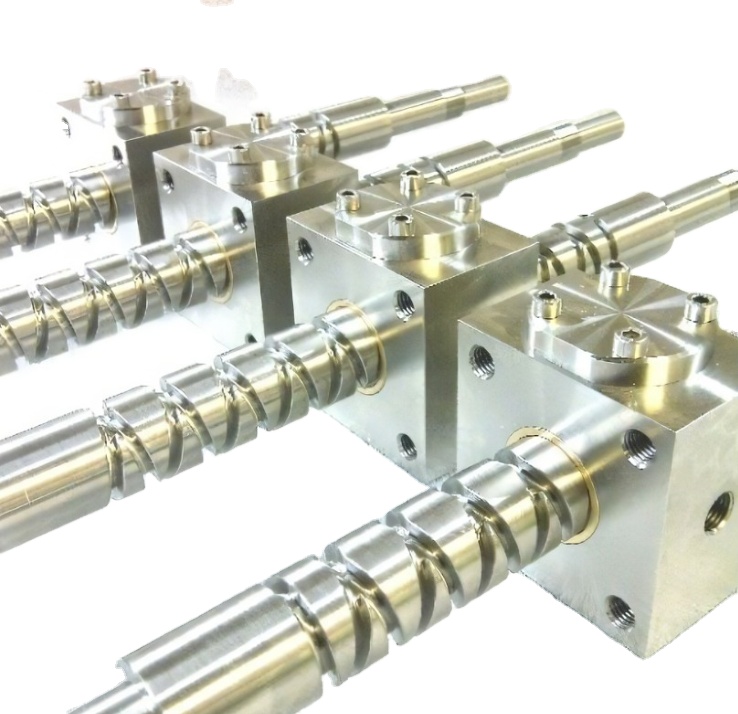

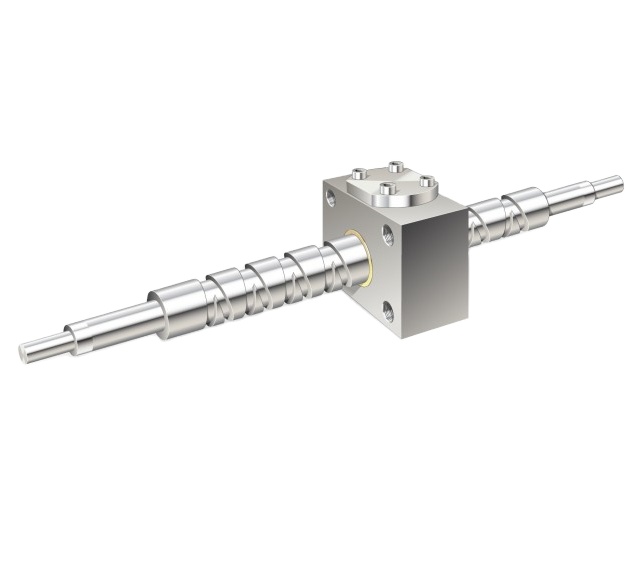

Self Reversing Screw tapping screw material

The material can be divided into steel 1022A, stainless steel 410, stainless steel 304.

1, carbon Self Reversing Screw, 1022A, standard heat treatment steel can be used as drilling screw production materials, after heat treatment, surface hardness HV560-750, core hardness HV240-450. Ordinary surface treatment is easy to rust, has high hardness, low cost;

2, stainless iron drilling screw, 410, heat treatment, rust ability is better than carbon steel. Worse than stainless steel;

3, stainless Self Reversing Screw, 304, can not do heat treatment, rust ability, low hardness, high cost, can only drill aluminum plate, wood, plastic plate;

4, composite drilling screw, the drill is made of carbon steel production, thread, and head combined with 304 stainless steel production process.

The processing method of self - drilling self - tapping screw

Is 1, self-drilling screw with tapping screw, a screw, with a bit through a dedicated electric tool construction, drilling, tapping, fixed, a complete lock, self-drilling screw with tapping screw sheet is mainly used in some parts of connection and fixed, such as Choi steel connection with Choi steel, color steel plate, and purlin, wall beam connections, etc., its penetration is generally not more than 6 mm, not more than 12 mm;

2. Self Reversing Screw and tapping screws are often exposed outdoors and have strong corrosion resistance. The rubber sealing ring can ensure that the screw is impervious to water and has good corrosion resistance;

3. Self Reversing Screw and tapping screws are suitable for the use of wood materials, that is, wood screws we often say, are generally manual operation, because of manpower restrictions, these kinds of screws are generally very small, the scope of use is relatively narrow;

4, Self Reversing Screw with tapping screw is combined tap and bolts, the front is a tap, followed by a thread, in generally softer material, drilling and well can be directly turned into an empty, by tap-tapping screw, followed by a bolt thread for the matter, if the screw diameter is small, the material is soft, not even use a first punch, such as screws into the wood;

5. Self Reversing Screw and tapping screws are usually described by screw diameter series, screw number per inch length, and screw length. There are 10 and 12 screw diameter series, the corresponding screw diameter is 4.87mm and 5.43mm respectively; There are 14, 16, and 24 threads per inch. The more threads per inch, the better the self-drilling capability.

|

Product Name

|

Self Reversing Screw

|

|||

|

Material of screw

|

steel , stainless steel , aluminium alloy or customer-specified

|

|||

|

Manufacturing process

|

Milled Thread

|

|||

|

Drawing format

|

JPEG,PDF,STEP

|

|||

|

Length

|

customer-specified

|

|||

FAQ

1.What parts can you buy from Bergek?

CNC machining milling parts / turning parts, stamping parts, sheet metal fabrication parts, bending parts

2.Why should you buy from Bergek not from other suppliers?

Focused on CNC machining and sheet metal fabrication, Provide one-stop solution for CNC turning, CNC milling, stamping bending, and sheet metal manufacturing.

3.Can Bergek make design drawings for me?

We do not provide design services. You are responsible for submitting 2D and 3D CAD drawings, and we can then provide a Design for Manufacturing review upon receiving your order.

4.What if I am not completely satisfied with the parts I receive?

We guarantee our materials and workmanship based on the terms of the initial order and the information provided by you. Any disputes based on a subjective determination shall be brought to the attention of management who will act in good faith to provide you with complete satisfaction. Our continuing business relies on earning your confidence in our ability to meet and exceed any reasonable expectations.

Our advantages:

Our advantages:

1. Years of manufacturing and export experience.

2. Products are supplied to many countries.

3. One-stop service from rubber molding parts to rubber extruded parts. Can save you time and money.

4. Internal mold design and manufacturing capability

click request quotation

Related Keywords