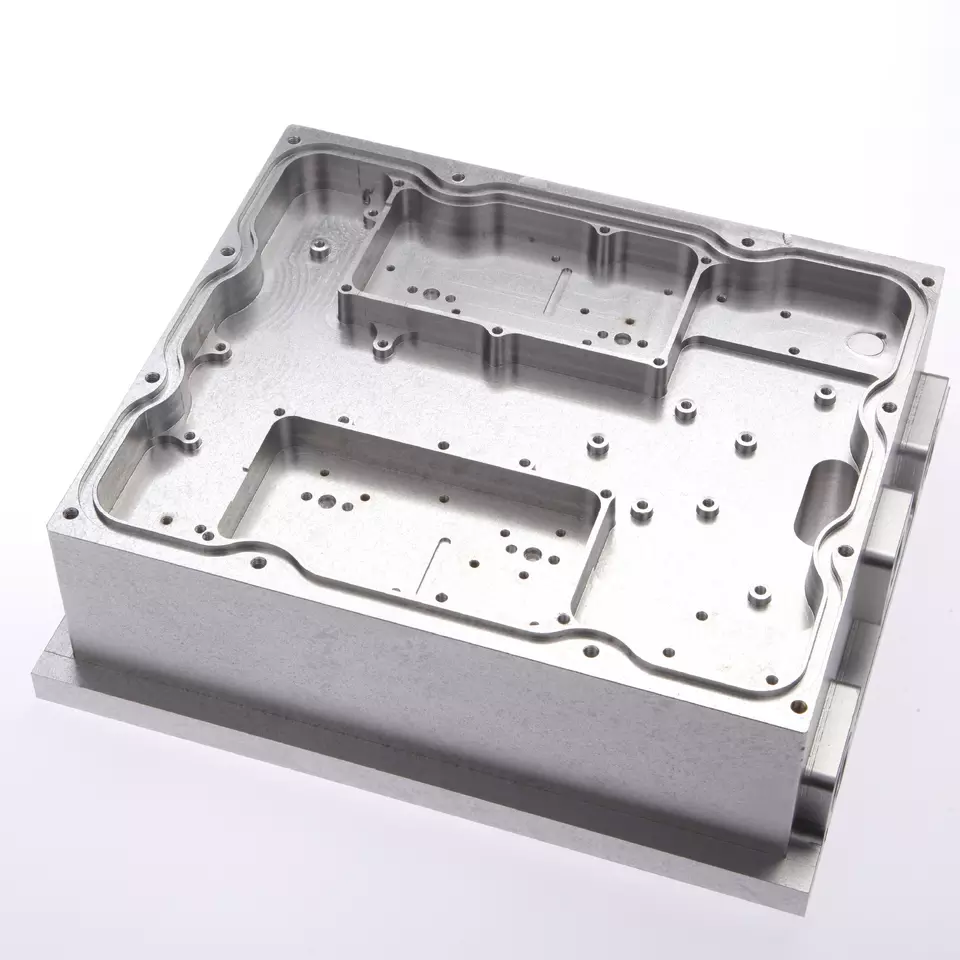

Precision metal CNC milling custom

-

$10.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- guangdong, shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | guangdong |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 1000 |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | CFR,FOB,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | guangdong,shenzhen |

CNC milling processing characteristics

1. Flexible, universal: CNC milling machine, machining center suitable for a variety of different structural shapes of the workpiece processing, can complete drilling, boring, reaming, milling plane, milling the inclined plane, groove milling, surface milling (CAM), tapping and other processing.

2. High machining accuracy: CNC milling machine and machining center has high machining accuracy, under normal circumstances can ensure the accuracy of the workpiece. In addition, CNC machining also avoids operating errors of the operator, and the size of the same batch of machined parts is good, greatly improving the quality of the product.

3. High production efficiency: CNC milling machine and machining center has the function of milling machine, boring machine, and drilling machine, so that the process is highly concentrated, greatly improving production efficiency and reducing the workpiece clamping error. The spindle speed of the CNC milling machine can realize the continuously variable speed, which is conducive to choosing the best cutting parameters. CNC milling machines with fast forward, fast rewind, and fast positioning function, can greatly reduce maneuver time.

4. It can process the shape of the complex: in addition to milling ordinary milling machines can mill various parts of the surface, but also can milling general milling machines can not mill plane curve contour and space surface contour, this is because the CNC machine has a plurality of feed coordinate axis linkage characteristics.

5. Reduce the labor intensity of the operator: CNC milling machine machining parts are automatically completed according to the pre-written processing program, the operator in addition to operating the keyboard, loading and unloading tools, workpiece, and intermediate measurement and observation of machine operation, do not need to carry out the heavy manual operation, greatly reduce the labor intensity.

Suitable for CNC milling processing content

1. Compared with ordinary milling machines, CNC milling machines have the characteristics of high machining accuracy, complex shape of machined parts, and wide processing range. According to the characteristics of a CNC milling machine, CNC milling machine processing mainly has the following types of content: curve contour or curved surface and other complex structures: workpiece curve contour, which refers to the parts have inside and outside contour for complex curve, the machined surface is parallel or perpendicular to the horizontal plane. In CNC milling processing, generally, only with the three-coordinate CNC milling machine, two coordinate linkages can be processed out.

The surface of the workpiece generally refers to the surface of the point on the three-dimensional space coordinate change surface, generally designed by a mathematical model, when machining the milling cutter and the processing surface is always point contact. The surface parts are usually processed by a three-coordinate CNC milling machine, which is often programmed and processed by computer.

2 in the ordinary milling machine processing difficulty of the workpiece structure: on the large size, marking and detection difficulties, the ordinary milling machine processing is difficult to observe and control the parts suitable for CNC milling machine processing, it is appropriate to choose CNC milling machine processing.

3. When it is processed on the ordinary milling machine, it is difficult to ensure the dimensional accuracy, shape accuracy, and surface roughness of the workpiece and other requirements, it is appropriate to choose the CNC milling machine.

4 consistency requirements of good parts: in mass production, due to the CNC milling machine itself positioning accuracy and repeated positioning accuracy are higher, can avoid in the ordinary milling machine processing human factors caused by a variety of errors, so the CNC milling machine is easy to ensure the consistency of batch parts so that its processing accuracy has been improved, the quality is more stable.

Product Pictures:

Related Keywords