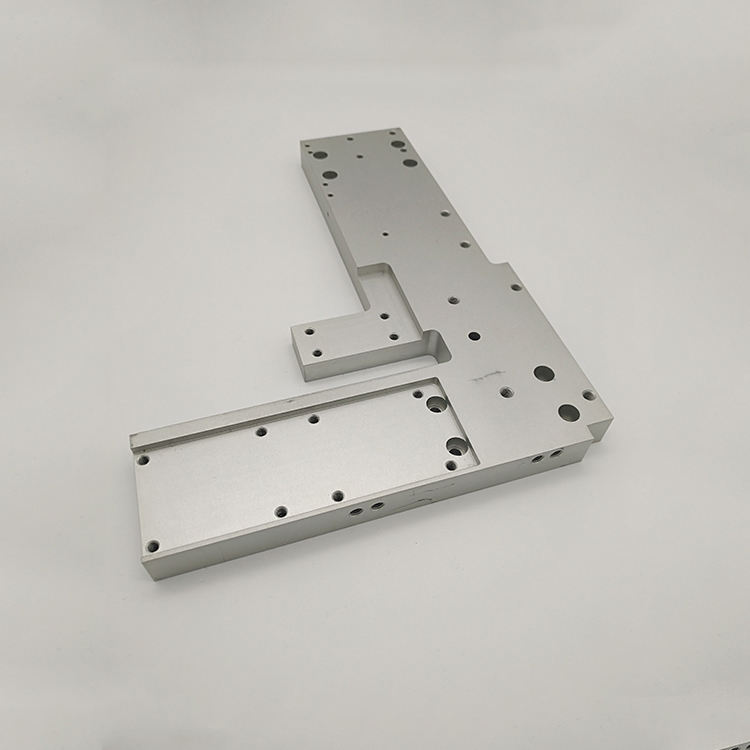

Customized CNC Milling Aluminum Parts

-

$5.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Express, Air

- Port:

- Guangdong, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 1000 |

| Payment Type: | T/T,Paypal |

| Incoterm: | CFR,FOB,CIF,EXW,FCA,DDP,DDU,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Express,Air |

| Port: | Guangdong,Shenzhen |

In specific applications, precision parts need to have higher precision, and precision can be more able to highlight the level of technology and product quality. Moreover, this kind of new product is more popular with customers. In general, CNC machining has a decisive competitive advantage and advantages in the field of production and processing. Their products are usually of high quality, so what are the advantages of CNC machining precision parts?

1. On the first hand, the working efficiency of CNC machining precision parts is higher. CNC machining parts processing can and production processing a number of processing surfaces. Compared with the ordinary machining center, it can save more production processes and improve efficiency, and the product quality of the CNC machining workpiece is better than that of the ordinary lathe. More reliability.

2, CNC machining precision parts processing in the new product research and development has an irreplaceable use. Generally speaking, the different structures of the complex parts can be programmed by the code to produce and process, and the design and production correction and content update only need to adjust the processing center program code, which can greatly shorten the development of new products.

3. The mechanical automation level of CNC machining precision parts processing is very high, which greatly reduces the manual work intensity of operators. The operator does not need to control the whole process like an ordinary lathe in the production and processing process, mainly to carefully observe and supervise the processing center. However, the technical difficulty of CNC machining is better than that of ordinary lathes, so it needs higher technical workers than ordinary lathes

product description

|

Material

|

1) Aluminum: AL 6061-T6, 6063, 7075-T etc.

|

|

2) Stainless steel: 303,304,316L, 17-4(SUS630) etc.

|

|

|

3) Steel: 4140, Q235, Q345B,20#,45# etc.

|

|

|

4) Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc.

|

|

|

5) Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc.

|

|

|

6) Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc.

|

|

|

Finish

|

Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish.

|

|

Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing.

|

|

|

Electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench).

|

|

|

Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc.

|

|

|

Main Equipment

|

CNC Machining center(Milling), CNC Lathe, Grinding machine.

|

|

Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc.

|

|

|

Drawing format

|

STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples.

|

|

Tolerance

|

+/-0.01mm ~ +/-0.05mm

|

|

Surface roughness

|

Ra 0.1~3.2

|

|

Inspection

|

Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM.

|

|

Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge.

|

|

|

Capacity

|

CNC turning work range: φ0.5mm-φ150mm*300mm.

|

|

CNC milling work range: 510mm*1020mm*500mm.

|

Picture case

FAQ

Q1:Are you a trading company or factory?

A1: We are direct factory with 15 experienced engineers and more than 150 employees as well approximate 10000 square meters workshop area.

Q2: Where can I get your product&price information?

A2: Send us inquiry through e-mail , we will contact you as we receive your mail.

Q3: What's kinds of information you need for quote?

A3: Kindly please provide the product drawing in PDF,and will be better you can provide in STEP or IGS

Q4: What shall we do if we do not have drawings?

A4: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q5: Will my drawings be safe after sending to you?

A9: Yes, we will keep them well and not release to third party without your permission.

Q6: Is it possible to know how are my products going on without visiting your company?

A10: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Related Keywords