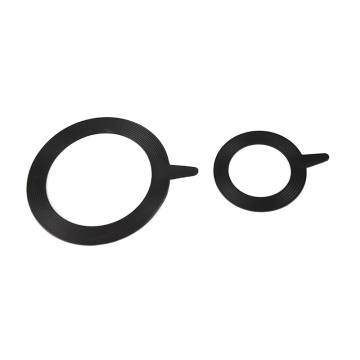

Flame Retardant Peek Gears

-

$6.50≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 800000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| HS Code: | NON |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Advantages of Peek Gear

1. High-temperature resistance

PEEK has a high glass transition temperature and melting point (334℃), which is one of the reasons why it can be used reliably in applications requiring heat resistance. Its load thermal variation temperature is up to 316℃ and its continuous service temperature is 260℃.

2. Wear resistance

PEEK material has excellent wear resistance under harsh environments such as high temperature, high load, and strong corrosion.

3. High strength

PEEK is a plastic with the best balance of mechanical strength, toughness, and rigidity. In particular, its excellent fatigue resistance to alternating stress is the most outstanding of all plastics, comparable to alloy materials.

4. Self-lubrication

PEEK has superior sliding characteristics in all plastics and is suitable for applications requiring a strict low coefficient of friction and wear resistance. In particular, carbon fiber and graphite mixed modified PEEK have better self-lubrication performance.

5. Chemical resistance (corrosion resistance)

PEEK has excellent chemical resistance. Concentrated sulfuric acid is the only chemical that can dissolve or destroy PEEK, and its corrosion resistance is similar to nickel steel.

6. The flame retardant

PEEK is a very stable polymer, 1.45mm thick sample, without any flame retardant can achieve the highest flame retardant standards.

7. Peel resistance

PEEK is good at stripping resistance, so it can be made into thin coated wire or electromagnetic wire and can be used under harsh conditions.

8. Fatigue resistance

PEEK has the best fatigue resistance of all resins.

9. Electrical performance

PEEK provides stable, excellent electrical performance over a wide range of temperatures and frequencies.

10. Radiation resistance

The ability of radiation resistance is very strong, more than the best radiation resistance of polystyrene in the general resin. It can be made into a high-performance wire with good insulation ability when the γ irradiation dose is up to 1100Mrad.

11. Hydrolysis resistance

PEEK and its composite materials are chemically resistant to water and high-pressure water vapor, and products made with this material maintain excellent properties under continuous use in high-temperature and high-pressure water.

Product parameters:

| Name | Peek Gear Peek Processing parts |

| Material | PEEK,PI,PEI,PU,PA,POM,PE,UPE,PTFE,etc. |

| Color | White,black,green,nature,blue,yellow,etc |

| Condition | In stock/ Made to order |

| Shape | As per your drawing |

| Physical Properties | Physical Properties of Advanced Engineering Plastics |

| Other Shape |

Sheet, rod, tube, gear, rack, pulley, guide rail, plastics fittings, and so on |

| Packing | Plastic bags, cartons, wooden case, pallet, container, etc. |

| Other |

Shipping status notification during delivery. Regular notification of new styles & hot selling styles. |

| Application |

Industry |

FAQ:

Q: Are you a trading company or a manufacturer?

A: We are A trading company and A manufacturer.

Q: What is your lead time?

A: Generally 5-10 days if available, 15-20 days if not

It depends on the quantity. In addition, for custom processed products, it is 8-12 days.

Q: Do you provide samples? Is it free or extra?

A: We can provide samples for regular products.

Related Keywords