DIY Mechanical Keyboard Case Custom

-

$10.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Guangdong, Shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 10000 |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,Express Delivery,DAF,DES,EXW,FAS,FCA,CPT,CIP |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Guangdong,Shenzhen |

Product Description

Product Description

The computer keyboard is now an integral part of the daily application on the computer, laptop keyboard, however, feel is often can not meet the requirements of users, choose a suitable external keyboard becomes routine, so various types of keyboard, appeared on the market at present there is a small keyboard is quietly rising, the metal shell is aluminum alloy mechanical keyboard. Mechanical keyboard for consumers is that has higher pursuit to the keyboard, the product of many modern young people to pursue, there are more and more the trend of the fire, if you are ready to enter the market, and have your own design, welcome to discuss with us, we will implement your own idea for you, here are some to share with you about the keyboard.

When you tap your fingers on a mechanical keyboard, you get a quick, direct, hard, clear, unambiguous response, which is the biggest difference from a thin-film keyboard.

The mechanical keyboard is made of high-grade materials and has a long service life.

ABS material is generally used for the conventional thin-film keyboard keycaps. This material is equivalent to our common plastic, after a long time will appear "oil" situation, a long time to use the film keyboard internal film will gradually age, and the feel sluggish. Mechanical keyboard commonly used PBT and POM, these two are high-grade materials, very wear-resistant.

Material: aluminum alloy, copper alloy, stainless steel alloy, steel alloy

Surface treatment: blackening, polishing, anodizing, chrome plating, zinc plating, nickel plating, coloring

3-5 days, 10-15 days for bulk orders, depending on your specific project

We have a professional team to control quality during mass production and check complete goods before shipment.

What are the advantages of a CNC machining DIY Mechanical Keyboard Case Custom?

1. Feel is excellent

When you tap your fingers on a mechanical keyboard, you get a quick, direct, hard, clear, unambiguous response, which is the biggest difference from a thin-film keyboard.

2. extremely long life

The mechanical keyboard is made of high-grade materials and has a long service life.

3. the material is excellent, durable

ABS material is generally used for the conventional thin-film keyboard keycaps. This material is equivalent to our common plastic, after a long time will appear "oil" situation, a long time to use the film keyboard internal film will gradually age, and the feel sluggish. Mechanical keyboard commonly used PBT and POM, these two are high-grade materials, very wear-resistant.

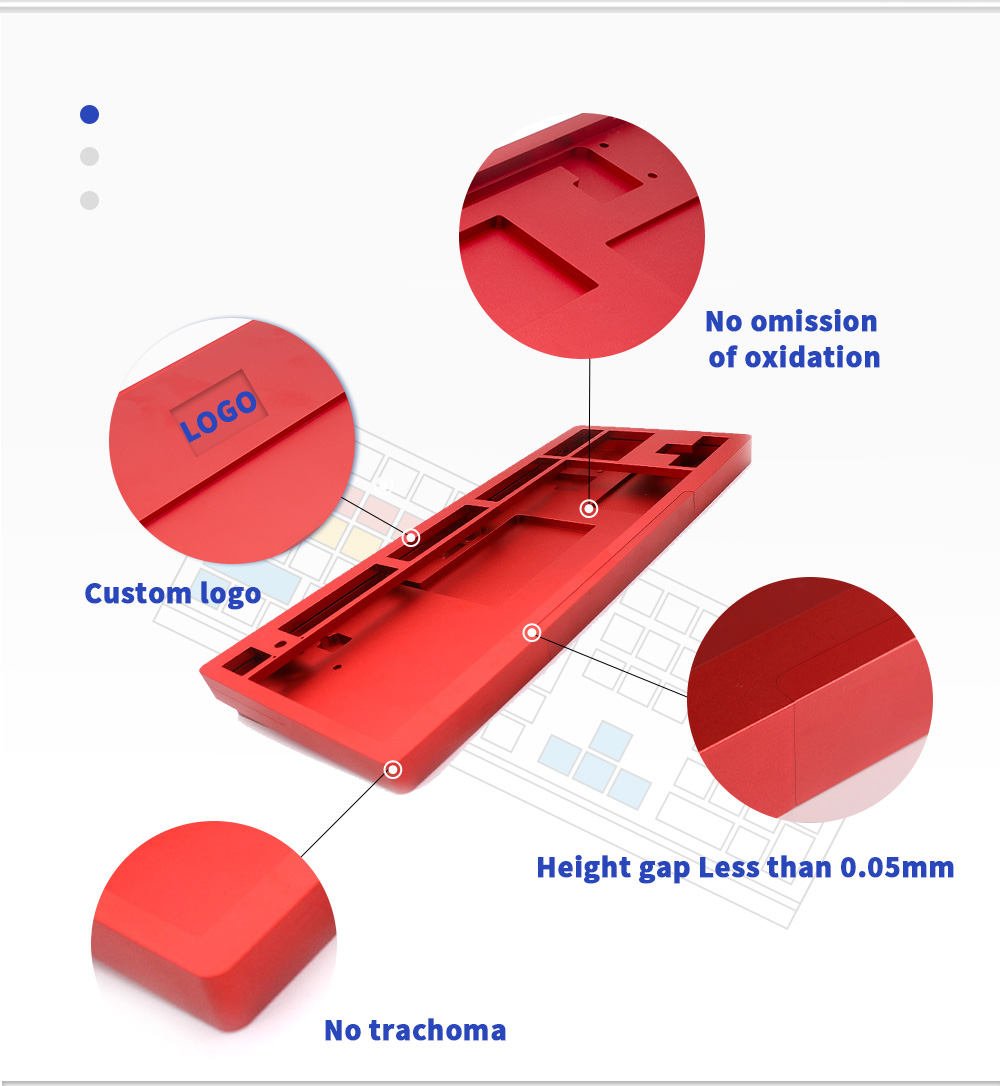

Details of customized products:

Material: aluminum alloy, copper alloy, stainless steel alloy, steel alloy

Surface treatment: blackening, polishing, anodizing, chrome plating, zinc plating, nickel plating, coloring

Production quality: our quality inspection procedures are quite strict, self-inspection is necessary during production, we have process inspectors and professional inspectors

Product case picture:

Often ask questions

Q1: How soon can I get the samples?

3-5 days, 10-15 days for bulk orders, depending on your specific project

Q2: How to control product quality?

We have a professional team to control quality during mass production and check complete goods before shipment.

Q3: What information is required for a quotation?

Please provide product drawings, we will give a specific quotation according to the drawings.

Bergek is a world-class manufacturing service provider in Shenzhen. We got advanced equipment to provide all-around customized products for manufacturers around the world, focusing on CNC machining and sheet metal fabrication.

End: Merchants who need customized products can send drawings to szbergek for quotation

click request quotation

Related Keywords

Related Keywords