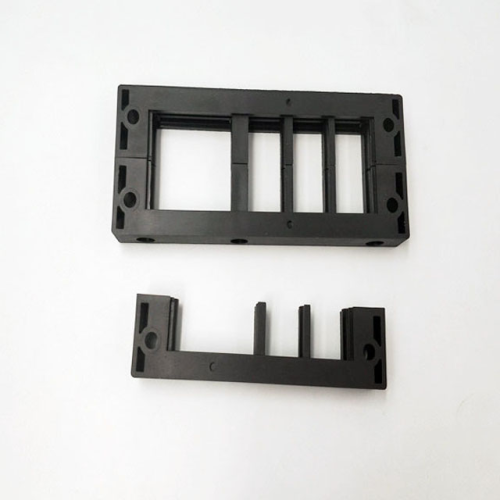

plastic injection molding service

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

After plastic is plasticized in the heating barrel of the injection molding machine, it is injected into the mold cavity of the closed mold by the plunger or reciprocating screw to form the plastic processing method of the product. This method can process products with complex shape, accurate size or with inserts, and has high production efficiency. Most thermoplastics and some thermosetting plastics (such as phenolic plastics) can be processed by this method. The material used for injection molding must have good fluidity before it can fill the mold cavity to obtain the product.

① Gating system refers to the plastic flow channel from the nozzle of the injection machine to the mold cavity

② Formed parts refer to the parts constituting the mold cavity, which are composed of female mold and male film

③ Structural parts, including guiding, film stripping, core pulling, parting and other parts. The mold is divided into fixed mold and moving mold, which are fixed on the fixed plate and moving plate of the mold closing device respectively. The moving mold completes the opening and closing action with the movement of the moving plate. The mold can be heated or cooled as needed.

Our company has more than ten years of manufacturing experience in injection molding products, with a yield of more than 97%, equipped with five full-automatic injection molding machines.

Why us?

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly, and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

click request quotation

Related Keywords