OEM Quick Turnaround CNC Machining Service

-

$6.50≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 800000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| HS Code: | NON |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

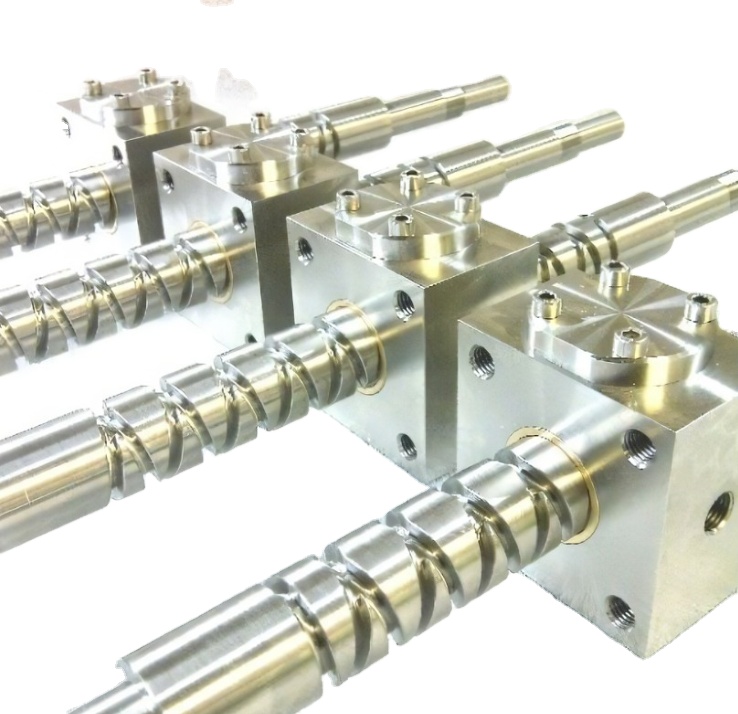

Quick Turnaround CNC Machining

As mechanical products become more sophisticated and complex, and frequent modifications are required. Especially the mechanical parts required in the fields of aerospace, shipbuilding, military, etc., require high precision, complex shapes, and small batches. Quick Turnaround CNC Machining processing has the advantages of strong adaptability, high processing accuracy, stable processing quality and high production efficiency, which can meet the customized needs of non-standard parts

Our Service

Materials

aluminum(6061-T6, 6063, 7075-T6, 5052) etc.

Brass / Copper / Bronze etc....

stainless steel(302,303,304,316,420) etc.

steel(Light steel,Q235,20#, 45# ) etc.

plastic(ABS, Delrin, PP, PE, PC,acrylic acid)etc.

Process

CNC machining, CNC turning, CNC milling, CNC lathe processing, CNC Boring, CNC grinding, CNC drilling etc.

Surface treatment

Transparent / color anodized; Hard anodizing; Powder coating;

Sand blasting, Laser carving, Silk screening;

Nickel plated, chrome, Galvanized, Silver / gold plating;

Black oxide coating; polishing;etc....

Manufacturability

Depends on the complexity of different products and quantities

Packaging

Customization

Design packaging according to your products;

Make the packagings according to your requests;

Print your LOGO on the packaging as long as you need;

Other request according to your need.

Quick Turnaround CNC Machining

As mechanical products become more sophisticated and complex, and frequent modifications are required. Especially the mechanical parts required in the fields of aerospace, shipbuilding, military, etc., require high precision, complex shapes, and small batches. Quick Turnaround CNC Machining processing has the advantages of strong adaptability, high processing accuracy, stable processing quality and high production efficiency, which can meet the customized needs of non-standard parts

Our Service

Materials

aluminum(6061-T6, 6063, 7075-T6, 5052) etc.

Brass / Copper / Bronze etc....

stainless steel(302,303,304,316,420) etc.

steel(Light steel,Q235,20#, 45# ) etc.

plastic(ABS, Delrin, PP, PE, PC,acrylic acid)etc.

Process

CNC machining, CNC turning, CNC milling, CNC lathe processing, CNC Boring, CNC grinding, CNC drilling etc.

Surface treatment

Transparent / color anodized; Hard anodizing; Powder coating;

Sand blasting, Laser carving, Silk screening;

Nickel plated, chrome, Galvanized, Silver / gold plating;

Black oxide coating; polishing;etc....

Manufacturability

Depends on the complexity of different products and quantities

Packaging

Customization

Design packaging according to your products;

Make the packagings according to your requests;

Print your LOGO on the packaging as long as you need;

Other request according to your need.

Quick Turnaround CNC Machining

As mechanical products become more sophisticated and complex, and frequent modifications are required. Especially the mechanical parts required in the fields of aerospace, shipbuilding, military, etc., require high precision, complex shapes, and small batches. Quick Turnaround CNC Machining processing has the advantages of strong adaptability, high processing accuracy, stable processing quality and high production efficiency, which can meet the customized needs of non-standard parts

Our Service

Quick Turnaround CNC Machining

As mechanical products become more sophisticated and complex, and frequent modifications are required. Especially the mechanical parts required in the fields of aerospace, shipbuilding, military, etc., require high precision, complex shapes, and small batches. Quick Turnaround CNC Machining processing has the advantages of strong adaptability, high processing accuracy, stable processing quality and high production efficiency, which can meet the customized needs of non-standard parts

|

Materials |

aluminum(6061-T6, 6063, 7075-T6, 5052) etc. Brass / Copper / Bronze etc.... stainless steel(302,303,304,316,420) etc. steel(Light steel,Q235,20#, 45# ) etc. plastic(ABS, Delrin, PP, PE, PC,acrylic acid)etc. |

| Process | CNC machining, CNC turning, CNC milling, CNC lathe processing, CNC Boring, CNC grinding, CNC drilling etc. |

|

Surface treatment |

Transparent / color anodized; Hard anodizing; Powder coating; Sand blasting, Laser carving, Silk screening; Nickel plated, chrome, Galvanized, Silver / gold plating; Black oxide coating; polishing;etc.... |

| Manufacturability | Depends on the complexity of different products and quantities |

|

Packaging Customization |

Design packaging according to your products; Make the packagings according to your requests; Print your LOGO on the packaging as long as you need; Other request according to your need. |

Q1:Will we Wo sign Non-Disclosure Agreements(NDA) ?

A:Yes.If it gives you peace-of-mind to sign an NDA,we are more than w ling to do so.But we have the rightkeep your design in confidential no matter NDA is signed or not.All factories are camera monitored.

Q2:How do I get a quote?

A:Please kindly provide us 3D or CAD solid model in Step, IGS,X_T format, normally Two-dimensional(2D)drawings are not adequate for accurate quoting or parts making B.Please tell us your requirement on quantisurface treatment.Color material,application enviranment for accurate pricing.

Q3:How quickly can l get my parts?

A:Quality parts can be made in 3-5 days if you provide us with complete 2Dand3DCAD models.Morecomplex parts requiring or other special features will take longer.As for shipping,most of our shipments arevia DHL, UPS,Fedex,which can take a few days from China to Europe or NorthAmerica.

Q4;How you do the quality control?

A: a.Materials inspection by IQC.

b.The fist sample inspected by QC,QC wild o over check as per the parameters list and critical dimensic requested by customers, to decide if it can go ahead for production.

c.During processing# our IP QC will check the injection molded parts every 2 hours,ensure no any rejects.

d.FQC will check the products before sending to the warehouse.

e.100% inspected by O QC before shipping out.

Related Keywords