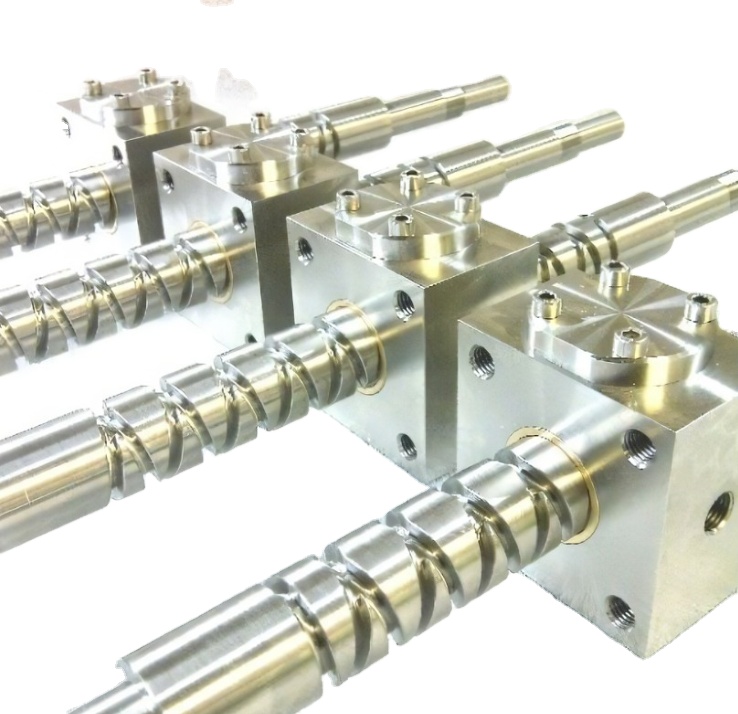

Cnc Machining Rapid Prototyping Machining service Parts

-

$6.50≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 800000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| HS Code: | NON |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Our Service

Materials

aluminum(6061-T6, 6063, 7075-T6, 5052) etc.

Brass / Copper / Bronze etc....

stainless steel(302,303,304,316,420) etc.

steel(Light steel,Q235,20#, 45# ) etc.

plastic(ABS, Delrin, PP, PE, PC,acrylic acid)etc.

Process

CNC machining, CNC turning, CNC milling, CNC lathe processing, CNC Boring, CNC grinding, CNC drilling etc.

Surface treatment

Transparent / color anodized; Hard anodizing; Powder coating;

Sand blasting, Laser carving, Silk screening;

Nickel plated, chrome, Galvanized, Silver / gold plating;

Black oxide coating; polishing;etc....

Manufacturability

Depends on the complexity of different products and quantities

Packaging

Customization

Design packaging according to your products;

Make the packagings according to your requests;

Print your LOGO on the packaging as long as you need;

Other request according to your need.

Our Service

Materials

aluminum(6061-T6, 6063, 7075-T6, 5052) etc.

Brass / Copper / Bronze etc....

stainless steel(302,303,304,316,420) etc.

steel(Light steel,Q235,20#, 45# ) etc.

plastic(ABS, Delrin, PP, PE, PC,acrylic acid)etc.

Process

CNC machining, CNC turning, CNC milling, CNC lathe processing, CNC Boring, CNC grinding, CNC drilling etc.

Surface treatment

Transparent / color anodized; Hard anodizing; Powder coating;

Sand blasting, Laser carving, Silk screening;

Nickel plated, chrome, Galvanized, Silver / gold plating;

Black oxide coating; polishing;etc....

Manufacturability

Depends on the complexity of different products and quantities

Packaging

Customization

Design packaging according to your products;

Make the packagings according to your requests;

Print your LOGO on the packaging as long as you need;

Other request according to your need.

Our Service

|

Materials |

aluminum(6061-T6, 6063, 7075-T6, 5052) etc. Brass / Copper / Bronze etc.... stainless steel(302,303,304,316,420) etc. steel(Light steel,Q235,20#, 45# ) etc. plastic(ABS, Delrin, PP, PE, PC,acrylic acid)etc. |

| Process | CNC machining, CNC turning, CNC milling, CNC lathe processing, CNC Boring, CNC grinding, CNC drilling etc. |

|

Surface treatment |

Transparent / color anodized; Hard anodizing; Powder coating; Sand blasting, Laser carving, Silk screening; Nickel plated, chrome, Galvanized, Silver / gold plating; Black oxide coating; polishing;etc.... |

| Manufacturability | Depends on the complexity of different products and quantities |

|

Packaging Customization |

Design packaging according to your products; Make the packagings according to your requests; Print your LOGO on the packaging as long as you need; Other request according to your need. |

FAQ

Q1:Will we Wo sign Non-Disclosure Agreements(NDA) ?

A:Yes.If it gives you peace-of-mind to sign an NDA,we are more than w ling to do so.But we have the rightkeep your design in confidential no matter NDA is signed or not.All factories are camera monitored.

Q2:How do I get a quote?

A:Please kindly provide us 3D or CAD solid model in Step, IGS,X_T format, normally Two-dimensional(2D)drawings are not adequate for accurate quoting or parts making B.Please tell us your requirement on quantisurface treatment.Color material,application enviranment for accurate pricing.

Q3:How quickly can l get my parts?

A:Quality parts can be made in 3-5 days if you provide us with complete 2Dand3DCAD models.Morecomplex parts requiring or other special features will take longer.As for shipping,most of our shipments arevia DHL, UPS,Fedex,which can take a few days from China to Europe or NorthAmerica.

Q4;How you do the quality control?

A: a.Materials inspection by IQC.

b.The fist sample inspected by QC,QC wild o over check as per the parameters list and critical dimensic requested by customers, to decide if it can go ahead for production.

c.During processing# our IP QC will check the injection molded parts every 2 hours,ensure no any rejects.

d.FQC will check the products before sending to the warehouse.

e.100% inspected by O QC before shipping out.

Related Keywords