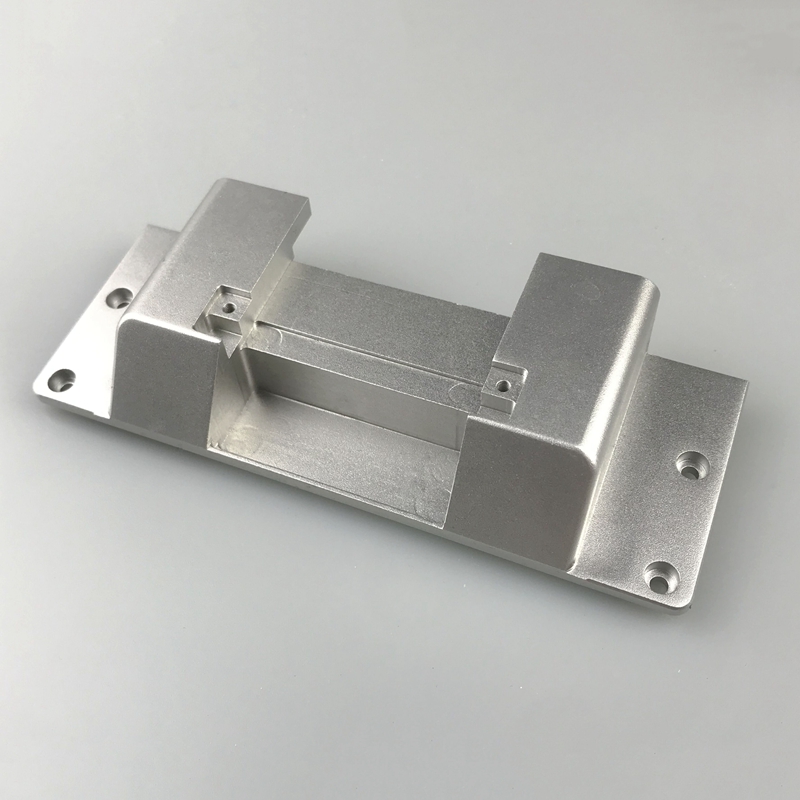

Small Batches Complex CNC Machining Service

-

$6.50≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 800000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| HS Code: | NON |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Product Introduction

The Complex CNC Machining is equipped with a tool holder and a tool magazine that can automatically change the tool, and the tool change process is automatically carried out under the control of the program. When the automatic CNC machine tool is processed, there is no need to manually control the tool, and the degree of automation is high. The benefits are obvious.

Product Features

Complex CNC Machining is an effective way to solve the problems of variable parts, small batches, complex shapes, and high precision, and to achieve high-efficiency and automated processing. lowers the requirements for operators; the product quality is stable and the flexibility is high. The automatic tool change of CNC machine tools makes the machining process compact and improves labor productivity. The machine tool can accurately process various contours, and some contours cannot be machined on ordinary machine tools.

CNC Machining for High-Tech Industry

Are you looking for economic milled parts of good quality? BERGEK is a professional CNC company in China, with advanced multi-axis machining centers and testing equipment, we provide customers with complex CNC machining service. Our experienced technicians are always looking for the best way to produce the highest quality CNC milled parts for clients.

With strong production capacity and rich experience, we can provide superior-precision but cost-effective custom CNC milling services for rapid prototyping and precision CNC milling and turning

Product Introduction

The Complex CNC Machining is equipped with a tool holder and a tool magazine that can automatically change the tool, and the tool change process is automatically carried out under the control of the program. When the automatic CNC machine tool is processed, there is no need to manually control the tool, and the degree of automation is high. The benefits are obvious.

Product Features

Complex CNC Machining is an effective way to solve the problems of variable parts, small batches, complex shapes, and high precision, and to achieve high-efficiency and automated processing. lowers the requirements for operators; the product quality is stable and the flexibility is high. The automatic tool change of CNC machine tools makes the machining process compact and improves labor productivity. The machine tool can accurately process various contours, and some contours cannot be machined on ordinary machine tools.

CNC Machining for High-Tech Industry

Are you looking for economic milled parts of good quality? BERGEK is a professional CNC company in China, with advanced multi-axis machining centers and testing equipment, we provide customers with complex CNC machining service. Our experienced technicians are always looking for the best way to produce the highest quality CNC milled parts for clients.

With strong production capacity and rich experience, we can provide superior-precision but cost-effective custom CNC milling services for rapid prototyping and precision CNC milling and turning

Product Introduction

The Complex CNC Machining is equipped with a tool holder and a tool magazine that can automatically change the tool, and the tool change process is automatically carried out under the control of the program. When the automatic CNC machine tool is processed, there is no need to manually control the tool, and the degree of automation is high. The benefits are obvious.

Product Features

Complex CNC Machining is an effective way to solve the problems of variable parts, small batches, complex shapes, and high precision, and to achieve high-efficiency and automated processing. lowers the requirements for operators; the product quality is stable and the flexibility is high. The automatic tool change of CNC machine tools makes the machining process compact and improves labor productivity. The machine tool can accurately process various contours, and some contours cannot be machined on ordinary machine tools.

CNC Machining for High-Tech Industry

Are you looking for economic milled parts of good quality? BERGEK is a professional CNC company in China, with advanced multi-axis machining centers and testing equipment, we provide customers with complex CNC machining service. Our experienced technicians are always looking for the best way to produce the highest quality CNC milled parts for clients.

With strong production capacity and rich experience, we can provide superior-precision but cost-effective custom CNC milling services for rapid prototyping and precision CNC milling and turning

FAQ

Q1:Will we Wo sign Non-Disclosure Agreements(NDA) ?

A:Yes.If it gives you peace-of-mind to sign an NDA,we are more than w ling to do so.But we have the rightkeep your design in confidential no matter NDA is signed or not.All factories are camera monitored.

Q2:How do I get a quote?

A:Please kindly provide us 3D or CAD solid model in Step, IGS,X_T format, normally Two-dimensional(2D)drawings are not adequate for accurate quoting or parts making B.Please tell us your requirement on quantisurface treatment.Color material,application enviranment for accurate pricing.

Q3:How quickly can l get my parts?

A:Quality parts can be made in 3-5 days if you provide us with complete 2Dand3DCAD models.Morecomplex parts requiring or other special features will take longer.As for shipping,most of our shipments arevia DHL, UPS,Fedex,which can take a few days from China to Europe or NorthAmerica.

Q4;How you do the quality control?

A: a.Materials inspection by IQC.

b.The fist sample inspected by QC,QC wild o over check as per the parameters list and critical dimensic requested by customers, to decide if it can go ahead for production.

c.During processing# our IP QC will check the injection molded parts every 2 hours,ensure no any rejects.

d.FQC will check the products before sending to the warehouse.

e.100% inspected by O QC before shipping out.

Related Keywords