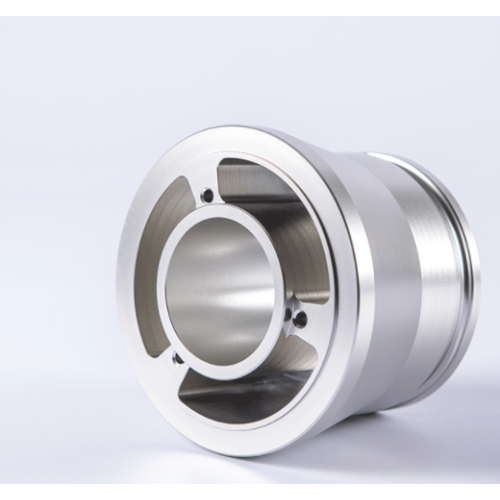

aluminum metal sheet fabrication

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

1, cold

Aluminum granules are used. The use of extrusion machine and mold molding, suitable for cylindrical products or stretching process difficult to achieve product shape, such as ellipse, square, rectangular products.

The tonnage of the machine used is related to the cross-sectional area of the product. The clearance between the upper die punch and the tungsten steel of the lower die is the product's wall thickness. The vertical clearance between the upper die punch and the tungsten steel of the lower die is the top thickness of the product.

Advantages: short mold opening cycle, low development cost relative to tensile mold.

Disadvantages: the production process is longer, the product size fluctuates greatly in the process, and the labor cost is high.

2, tensile

The aluminum skin is used. The use of continuous die machine and die for multiple deformations to achieve the shape of the demand, suitable for non-cylindrical (aluminum products with bending).

Surface treatment of aluminum products

1, sandblasting (shot blasting)

The process of cleaning and coarsening metal surfaces using the impact of high-speed sand flow.

This method of aluminum surface treatment can make the surface of the workpiece obtain a certain cleanliness and different roughness so that the mechanical properties of the workpiece surface is improved, to improve the fatigue resistance of the workpiece, increase the adhesion between it and the coating, prolong the durability of the coating film, but also conducive to the flow and decoration of the coating. This process is often seen in various Apple products.

2, polishing

A process in which the surface roughness of the workpiece is reduced by mechanical, chemical, or electrochemical action to obtain a bright, smooth surface. The polishing process is mainly divided into mechanical polishing, chemical polishing, electrolytic polishing. Aluminum parts using mechanical polishing + electrolytic polishing can be close to the stainless steel mirror effect, this process, give a person with high-grade simple, fashionable future feeling.

3, drawing

Metal wire drawing is a manufacturing process in which aluminum sheets are repeatedly sanded out of the wire. Drawing can be divided into a straight-line drawing, random drawing, spiral drawing, thread drawing. The metal wire drawing process can clearly show each fine silk mark, so that the metal matte out of the fine hair luster, the product has fashion and sense of science and technology.

4, high light cutting

The diamond cutter is reinforced by the fine carving machine in the high-speed rotation (general speed of 20000 RPM) on the spindle of the fine carving machine to cut parts, resulting in a local highlighting area on the surface of the product. The brightness of the cutting highlights is affected by the speed of the milling bit. The higher the speed of the bit, the brighter the highlights will be, and the darker and more likely to produce the cutter grain. High light cutting in the use of mobile phones, such as iphone5, in recent years, some high-end TV metal frame using high light milling process, coupled with anodic oxidation and wire drawing process makes the whole TV is full of fashion sense and sharp sense of science and technology.

5, anodic oxidation

Anodic oxidation refers to the electrochemical oxidation of the metal or alloy, aluminum and its alloy in the corresponding electrolyte and specific process conditions, due to the action of the impressed current, aluminum products (anode) on the formation of a layer of the oxide film process. Anodic oxidation can not only solve the defects of aluminum surface hardness, wear-resistance and other aspects, but also prolong the service life of aluminum and enhance the aesthetic degree, has become an indispensable part of aluminum surface treatment, is currently the most widely used and very successful process.

6. Dual-color anode

Two-color anodizing refers to anodizing a product and giving specific areas different colors. Dual-color anodic oxidation process is seldom used in the TV industry because of its complexity and high cost. But through the contrast between the two colors, more can reflect the high-end, unique appearance of the product.

Why us?

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly, and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

click request quotation