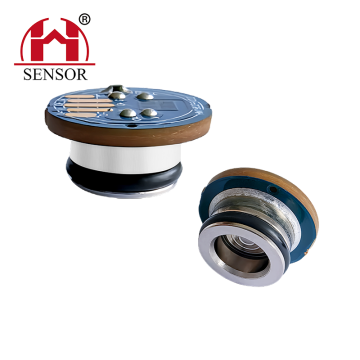

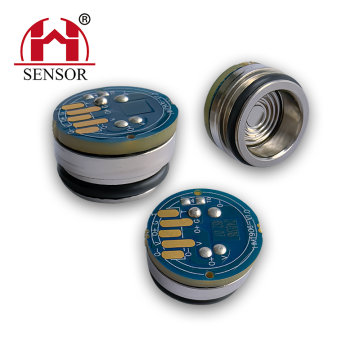

Pressure sensors for medical devices

-

$25.00≥100 Piece/Pieces

- Min. Order:

- 100 Piece/Pieces

- Min. Order:

- 100 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Jiangmen, Guangzhou, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong |

|---|---|

| Productivity: | 100000pcs/month |

| Supply Ability: | 100000pcs/montjh |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Land,Air |

| Port: | Jiangmen,Guangzhou,Shenzhen |

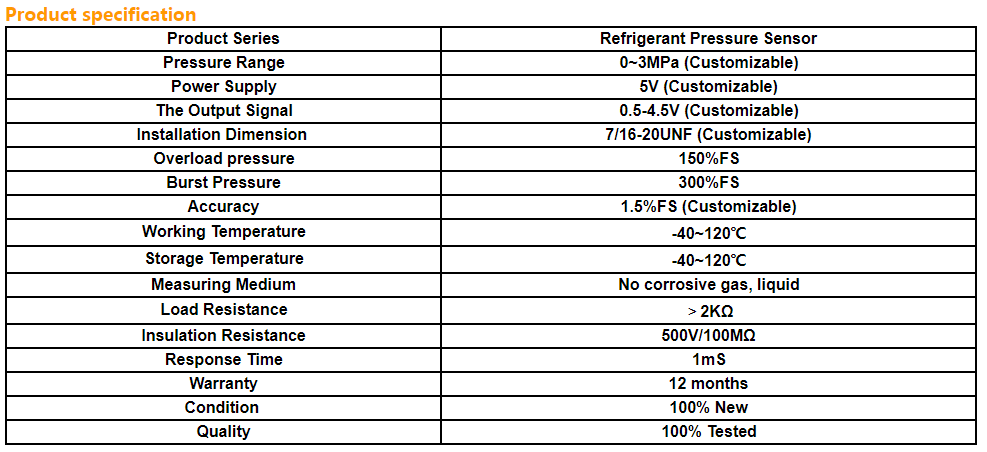

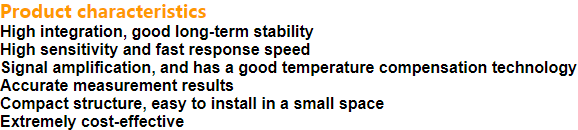

Product description

Refrigerant pressure sensor fault judgment method: power separately, see whether the zero output is accurate; If you apply pressure precisely, see if the output changes. If there is any change, the sensor is fine. Sensor is a kind of detection device, it can perceive the measured information, and the measured information according to certain rules into electrical signals or other required information output form, so as to meet the requirements of information transmission, processing, storage, display, record and control. Troubleshooting steps of high pressure sensor: if there is dust on the fin, clean it with water; If there is a lot of floss (especially floss floating around May), clean the fins and keep the condenser fins clean. Check the empty stroke of the machine distribution box. If the trip indicates too high or too low current. Use a screwdriver to close the fan blade. If it is too wrinkled, it indicates that the fan bearing is damaged or the fan is burned, and the bearing or fan needs to be replaced. If no, the high voltage switch is faulty and needs to be replaced. After checking and troubleshooting, disconnect the QS gas of the machine, disconnect the power again, the machine can operate normally. Specializing in the manufacture of urea pressure sensor, common rail pressure transmitter, engineering hydraulic sensor, injection molding machine special pressure sensor.

Related Keywords