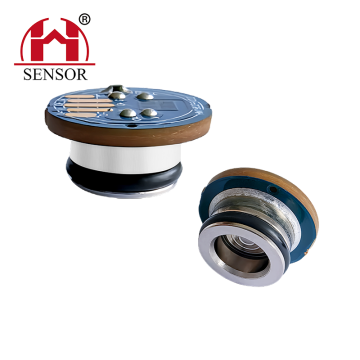

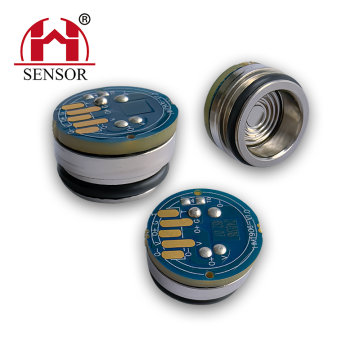

Manufactures of sensors for injection molding machines

- Min. Order:

- 100 Piece/Pieces

- Min. Order:

- 100 Piece/Pieces

- Transportation:

- Ocean, Air, Land, Express, Others

- Port:

- GuangZhou, JiangMen, ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100000pieces/Month |

|---|---|

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES |

| Transportation: | Ocean,Air,Land,Express,Others |

| Port: | GuangZhou,JiangMen,ShenZhen |

Product description

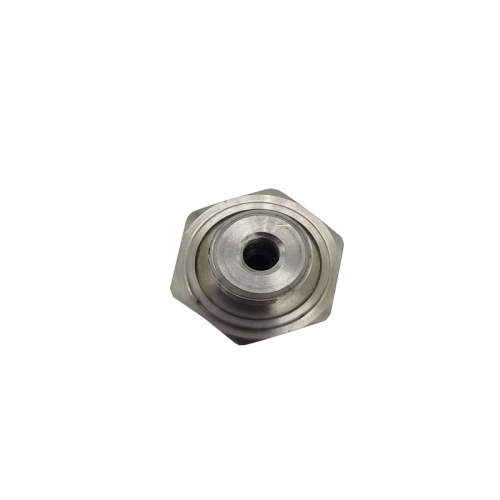

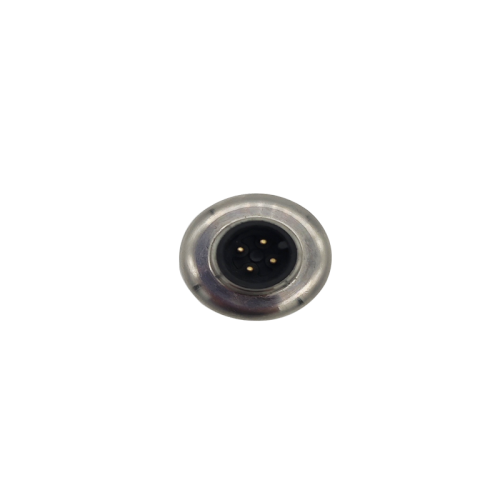

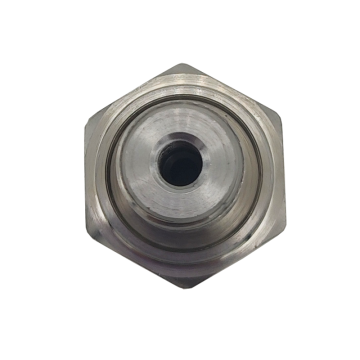

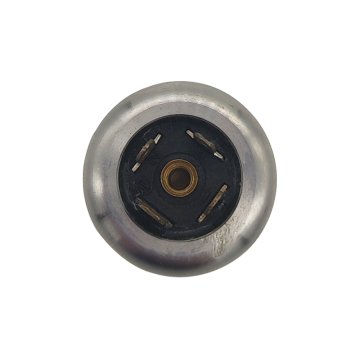

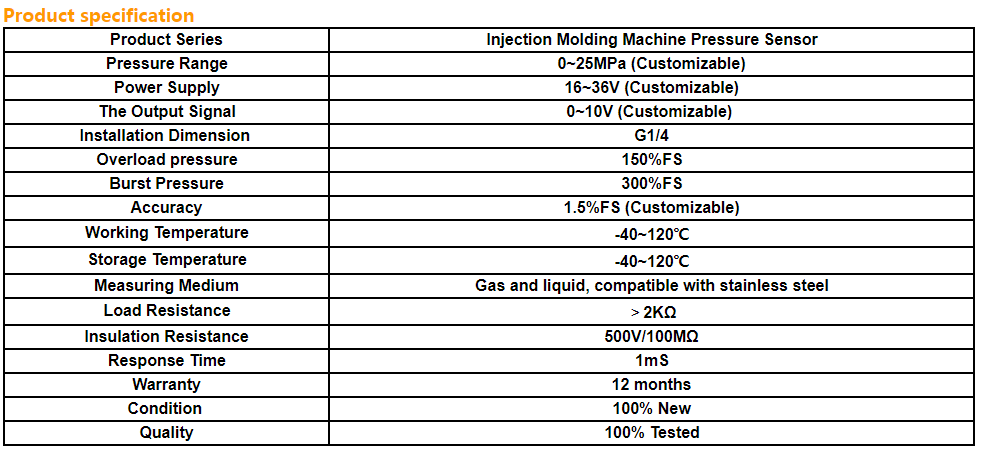

Injection Molding Industry 4.0 means thorough process control. Today, a suite of automated and digital technologies is developed to perform all levels of process control. These technologies include on-machine and in-model sensors, artificial intelligence approaches such as machine learning, big data, neural networks, and more. In order to meet the requirements of industry 4.0, a large amount of manufacturing process control data is needed. While online data from the machine is valuable for process monitoring and control, the most accurate processing data comes from the molds that form the plastic parts. Therefore, in-module process control is very important. The process parameters in the mold are detected by the sensor. Different kinds of sensors can be used for different purposes and sensing methods. However, for mode process control, two types of sensors dominate - pressure and temperature sensors. Specializing in the manufacture of intake manifold absolute pressure sensor, common rail pressure transmitter, engineering hydraulic sensor, injection molding machine special pressure sensor, urea pressure sensor, air compressor pressure transmitter, etc.

Related Keywords