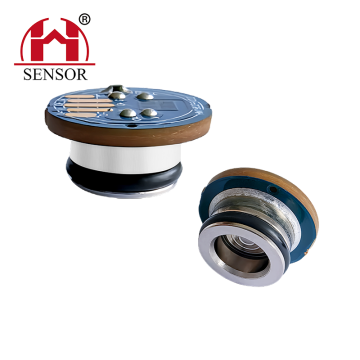

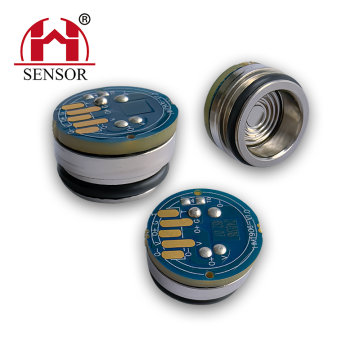

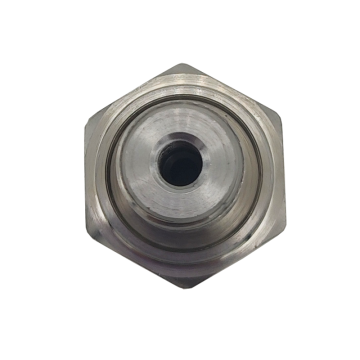

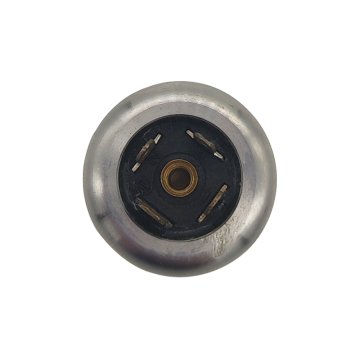

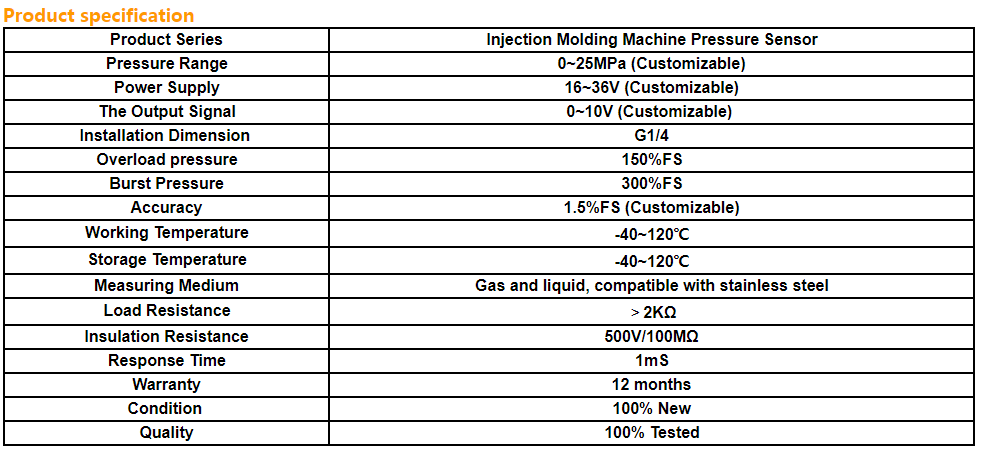

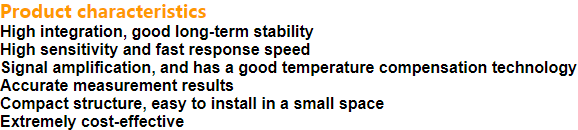

High quality injection molding machine sensor HM5607B

- Min. Order:

- 100 Piece/Pieces

- Min. Order:

- 100 Piece/Pieces

- Transportation:

- Ocean, Air, Land, Express, Others

- Port:

- GuangZhou, JiangMen, ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100000pieces/Month |

|---|---|

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DDP,DEQ,DDU,DAF,DES,Express Delivery |

| Transportation: | Ocean,Air,Land,Express,Others |

| Port: | GuangZhou,JiangMen,ShenZhen |

Product description

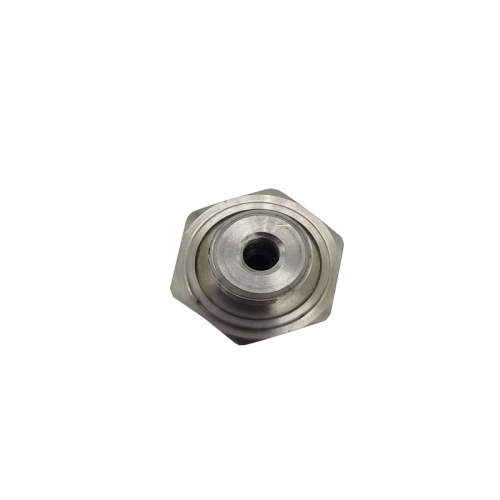

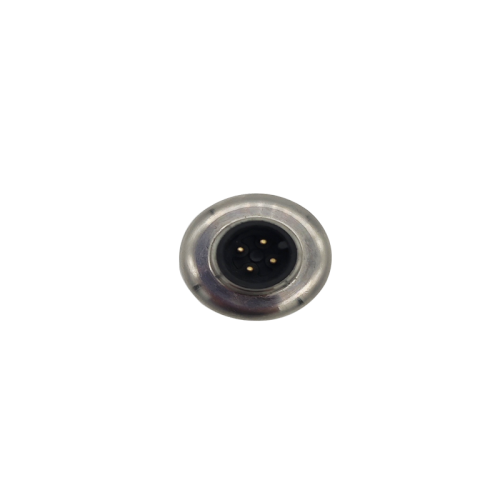

Mold designers and manufacturers also need to determine the position of the groove of the injection molding machine pressure sensor in the mold cavity and the position of the wire or cable outlet. The design principle is that the wire or cable can not move freely after screwing out the mold. It is common practice to attach a connector to the base of the mold, and then use another cable to connect the mold to the injection molding machine and auxiliary equipment. There are two types of pressure sensors used between injection molding machines, namely flush type and indirect type. The flush sensor is inserted between the cavities by drilling a splice hole in the back of the cavity. Its top is flush with the surface of the cavity. The cable passes through the block and is connected to the monitoring system interface located on the outer surface of the block. The advantage of this injection molding machine pressure sensor is that it will not be disturbed by the downward force during the demoulding process, but it is easy to damage under high temperature conditions, resulting in joint difficulties. Specializing in the manufacture of urea pressure sensor, common rail pressure transmitter, engineering hydraulic sensor, injection molding machine special pressure sensor, water purifier pressure transmitter, etc.

Related Keywords