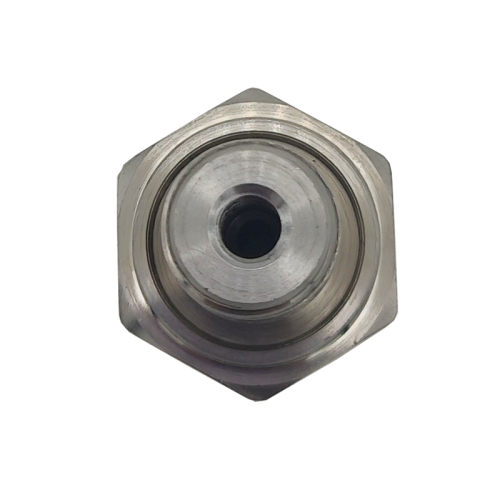

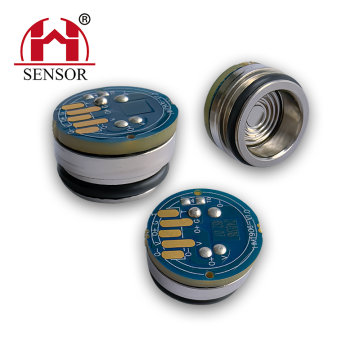

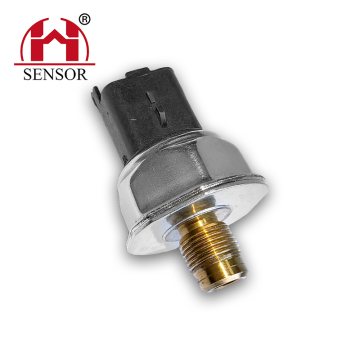

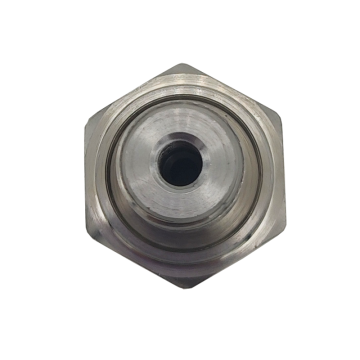

Automatic pressure sensor for injection molding machine

- Min. Order:

- 100 Piece/Pieces

- Min. Order:

- 100 Piece/Pieces

- Transportation:

- Ocean, Air, Land, Express, Others

- Port:

- GuangZhou, JiangMen, ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | GuangDong |

|---|---|

| Productivity: | 100000pieces/Month |

| Supply Ability: | 100000pieces/Month |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Air,Land,Express,Others |

| Port: | GuangZhou,JiangMen,ShenZhen |

Product description

According to the different test pressure type, injection molding machine pressure sensor can be divided into gauge pressure sensor, differential pressure sensor and absolute pressure sensor.Application of injection molding machine pressure sensor in petrochemical industry: Pressure sensor is one of the measuring devices used in petrochemical industry automatic control. In large chemical projects, almost all pressure sensors are used.Differential pressure, absolute pressure, gauge pressure, high pressure, differential pressure, high temperature, low temperature and all kinds of materials and special processing of the remote flange pressure sensor. Almost the petrochemical industry's demand for pressure sensors mainly focuses on three aspects: reliability, stability and high accuracy. Among them, reliability and many additional requirements,such as range ratio, bus type, etc., depend on the structural design of the transmitter, the level of processing technology and structural materials.The stability and high precision of pressure transmitter are mainly guaranteed by the stability and measuring precision of pressure sensor.

Related Keywords