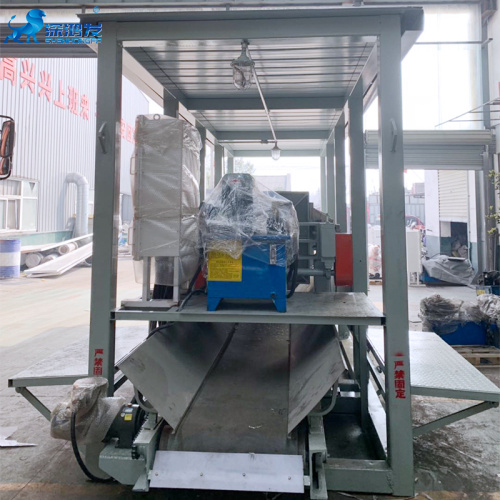

Program Controlled Automatic Filter Press

-

$4000.00≥1000 Set/Sets

- Min. Order:

- 1000 Set/Sets

- Min. Order:

- 1000 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Tianjin, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100sets/month |

| Supply Ability: | 100sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,FAS,FCA |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Tianjin,Shanghai |

Overview

On-board integrated filter press is a kind of solid-liquid separation equipment which is convenient for on-board movement. The equipment has greatly improved the traditional van type filter press, and integrates many advantages such as low investment cost, small footprint, simple operation and maintenance. The equipment is used in sludge treatment fields such as sludge dewatering, river dredging and oilfield drilling, which can effectively reduce the secondary pollution of sludge to the environment and achieve the goal of low-cost resource utilization of sludge.

In the process of sludge treatment, a variety of new technologies have appeared, although there are differences due to the internal characteristics and state of sludge, sludge dewatering is the key of sludge treatment. The next process after sludge concentration is sludge dewatering. The effect of sludge dewatering directly affects the operating cost of subsequent treatment. In general, when it is difficult to dehydrate the sludge, or when the solid content of the dehydrated sludge is required to be relatively high, it is advisable to use the van filter press. The vehicle-mounted integrated filter press is optimized and improved on the basis of the van type filter press with better performance. Therefore, as the key equipment of sludge dehydrating process, the development of the vehicle-mounted integrated filter press is particularly important.

Working principle of vehicle-mounted filter press

The vehicle-mounted integrated filter press uses the variable filter chamber filter unit composed of filter plate and filter cloth to separate solid and liquid materials under the condition that the oil cylinder presses the filter plate and is assisted by the feed pump. The feed pump will send the filtered material to the filter unit of the equipment (filter chamber), through the filter cloth in the filter chamber, the liquid will be seep out of the filter cloth, and the solid will be intercepted in the filter chamber and form the filter cake. After the filtration is completed, the oil cylinder will relieve pressure, and the filter plate will be pulled apart one by one under the action of the pull-plate system. The filter cake in the filter chamber will fall on the filter cake conveying device under the filter plate by its own weight. It can be delivered directly to the transport equipment.

Program-controlled filter press is simple, covers an area of less, less investment, the equipment is especially suitable for sludge treatment and other fields.

Related Keywords