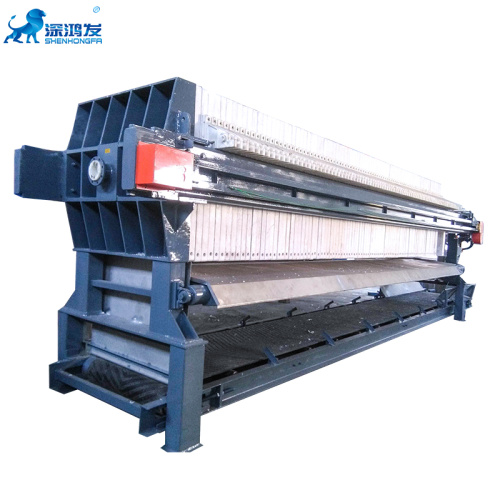

Conveyor Equipped with Programmable Controller PLC

-

$6000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100sets/month |

| Supply Ability: | 100sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,FAS,FCA |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Qingdao,Shanghai |

Application of program - controlled filter press with conveyor:

Filter cake automatic conveying filter press is widely used in small scale sand making mud dehydration, washing sand mud dehydration, mine tailings dehydration, piling mud dehydration pile water separation Ceramic sludge dehydration, paper making sludge dehydration, textile printing and dyeing sludge dehydration, municipal sewage treatment plant sludge dehydration, slaughter meat processing sludge dehydration, kaolin dehydration, alumina sludge dehydration, pile foundation engineering mud dehydration, stone processing sludge dehydration, wood processing sludge dehydration, leather processing sludge dehydration, food processing sludge dehydration, electroplating circuit board sludge dehydration, river sludge removal Application of sludge dewatering in various types of industrial wastewater such as water, coal washing and tail coal dewatering.

Working principle of program - controlled filter press with conveyor:

Under the action of the hydraulic cylinder, the filter plate of the filter press moves along the main beam and press tightly, so that the adjacent filter plate forms a filter chamber and the surrounding seal. Slime water through the human material pump with a certain pressure from the human material hole to the filter chamber, with the help of the feeding pressure of the human material pump on both sides of the filter medium to achieve solid-liquid separation, slime particles remain in the filter chamber, filtrate through the filter medium from the filter plate of the water hole out of the machine. After a period of time, the filtrate no longer flows out and the filtration and dehydration process is complete. Stop feeding, pull the filter plate by the chain, the filter cake falls off, by the filter press under the scraper conveyor or belt machine transport.

Application Case

Related Keywords