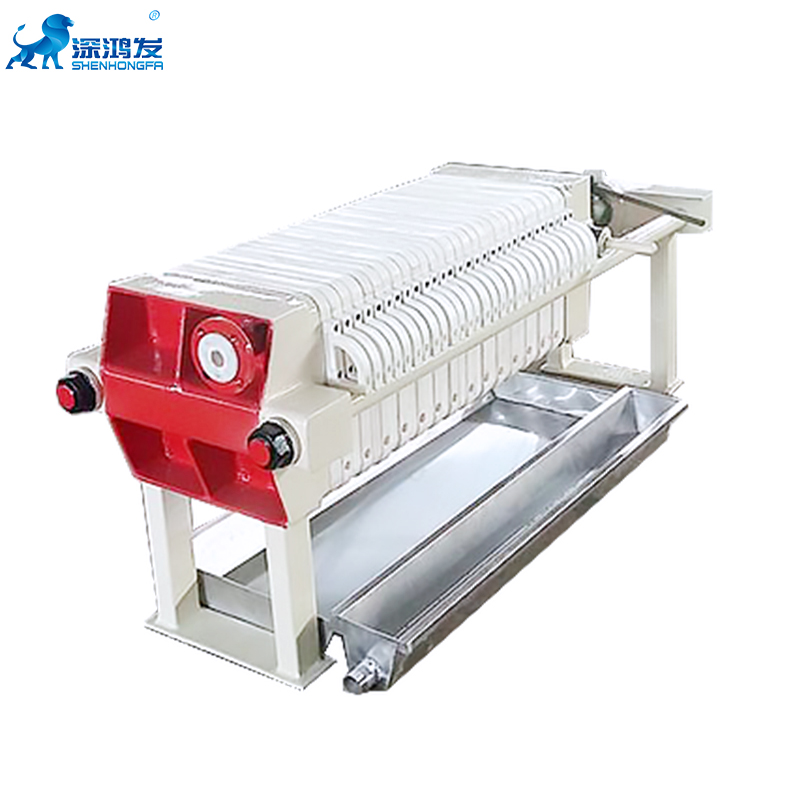

Plate and frame Hydraulic sludge Dewatering Filter Press

-

$3000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Tianjin, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 200sets/month |

| Supply Ability: | 200sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,FAS |

| Certificate: | CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Tianjin,Shanghai |

Plate and frame Hydraulic sludge Dewatering Filter Press

The plate and frame filter press is extruded to make the extruded sludge filter cloth filter cloth discharge the purpose of filter cloth filter cloth discharge. . It consists of a recessed filter plate filter plate, a frame frame filter plate vibration system, an air pressure reduction device, a filter cloth high-pressure flushing device, and a photoelectric protection device on the side of the fuselage.

The plate and frame filter press is composed of plates and frames arranged alternately. Both sides of the filter plate are covered with filter cloth, and the plate and frame are pressed tightly by a pressing device, that is, a filter press chamber is formed between the plates. There are small holes on the same part of the upper end of the board and the frame, and each hole is connected into a channel after being pressed. With a certain pressure, the chemically conditioned sludge is pressed in through this channel, and enters each pressure filter chamber through the branch channel of each filter frame.

Under pressure, the filtrate passes through the filter cloth and is discharged from the filter press through the pores, while the solids are retained and form a filter cake on the surface of the filter cloth. When the filter cake completely fills the filter press chamber, the dehydration process is over, and the sludge should be stopped feeding into the filter press at this time. Then, open the filter press, pull out each filter plate in turn, peel off the filter cake, and clean the filter cloth.

Our Engineering Project

Advantages of Shenzhen HONGFA Filter Press:

1. Low filter cake moisture;

2. Unmanned operation and cost saving;

3. Resist high temperature and corrosion;

4. Good sealing effect can perfectly avoid leskage;

5. Energy saving high performance chamber filter press with long working life

Related Keywords