Plate and frame diatomite filter machine

-

$2000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Tianjin, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 100set/month |

| Supply Ability: | 100sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR |

| Certificate: | CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Tianjin,Shanghai |

Plate and Frame Filter Press for Diatomaceous Earth

Diatomaceous earth filter, including the filter tank, its characteristics lie in the filter tank, diatomaceous earth filter plate is provided with an inlet and outlet, the inlet and outlet are provided with a liquid pouring sleeve.The each filter plate is provided with a negative pressure groove, the negative pressure groove is covered with a press cloth, the inlet is connected with the cavity above the press cloth, the outlet is connected with the negative pressure groove under the filter cloth, The use of this technology to coat diatomite fast, stable coating does not fall off, does not crack, filter area is large, filter quality is good, because of energy saving, labor saving, time saving, and improve the production efficiency.

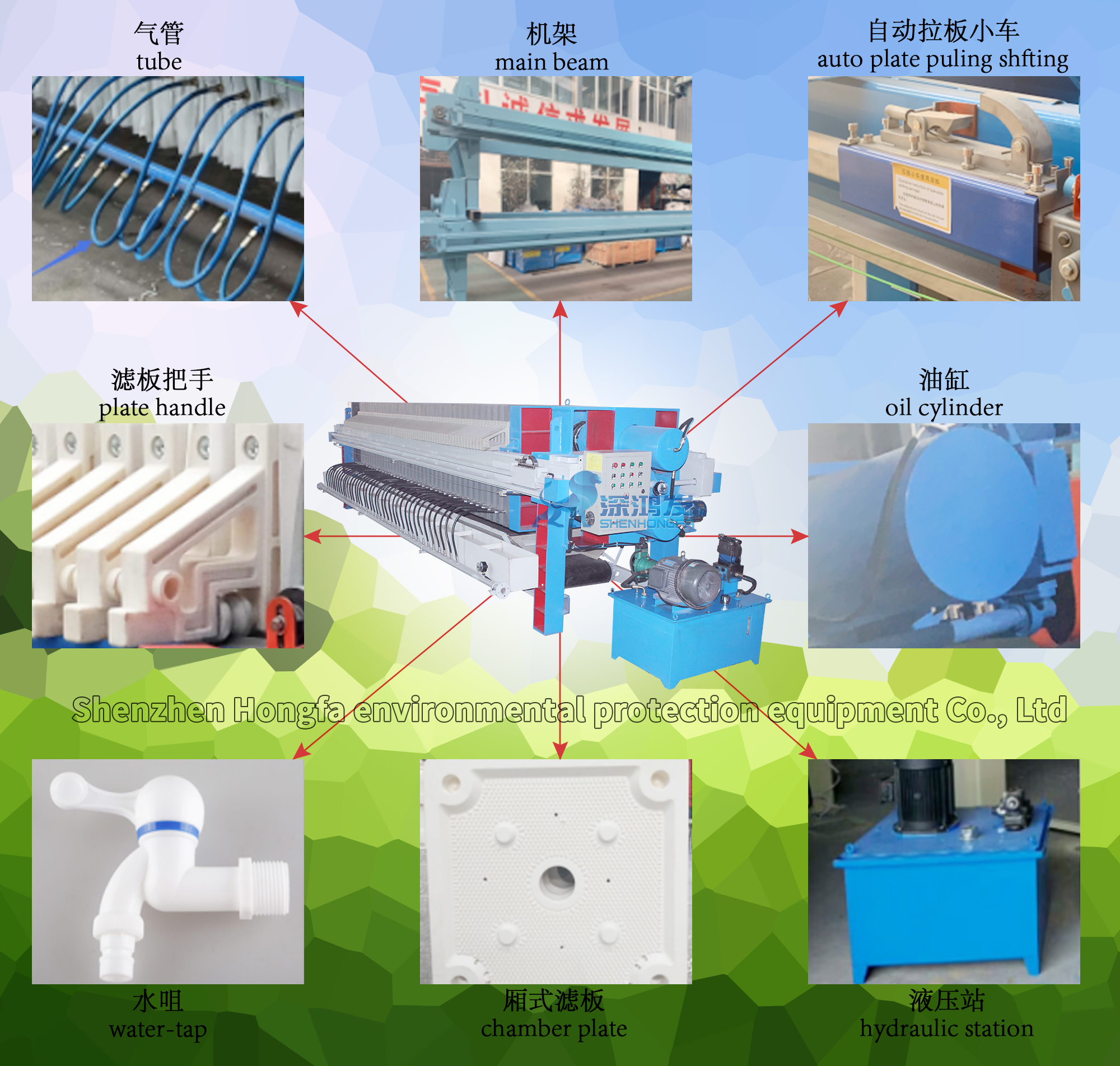

Main components of filter press:

> Frame: The steel frame acts as a clamping device for the filter plates.

> Filter Plates: A filter cake forms in the chambers between filter plates.

> Filter Cloth: A cloth filter that is attached to both sides of a filter plate. Solids build up on cloth to form a filter cake, separating liquids from solids.

Types of Filter Press according to:

> Closing mode: manual, gear drive, hydraulic;

> Filtrate flow: open flow, close flow, cake washing, non-cake washing, center feeding, corner feeding,etc..

> Filter plate structure: recessed plate, plate &frame, diaphragm squeeze (membrane) plate;

> Filter plate material: PP, rubber, cast iron, stainless steel;

> Filter Plate size: 320, 450, 630, 800,1000, 1250, 1500, 2000

We have professional team in sludge filteration which have many research staffs who have devoted themselves to the industry for more than 20 years, and our High-Efficiency Circular Filter Press for Sludge, saled all over the world.

1),Long history : our factory established in 2014,and we are the leading enterprise in filter press industry .

2),we are one of the main constitutor of press filter regulations.

3),we are a professional team which have many research staffs who have devoted themselves to the industry for more than 20 years.

4),We offer different material's filter plate according to different industry , while other providers couldn't make it .

5), Our products are sold to many companies which most of them are top500 .

6),We manufacture the filter plate ourselves , so we could guarantee its quality ,while other providers buy it from others

WORK SHOP

Product Description

1) The plate-frame sludge filter press is an intermittent solid-liquid separation device.

2) It consists of a filter plate and a filter frame arranged to form a filter room. Under the pressure of the feed pump, the feed liquid is sent to each filter room through filtration.

3) Medium, separating solids from liquids. It has the advantages of good separation effect, wide application scope, simple operation, and low investment.

4) Especially for the separation of viscous material, it has unparalleled superiority

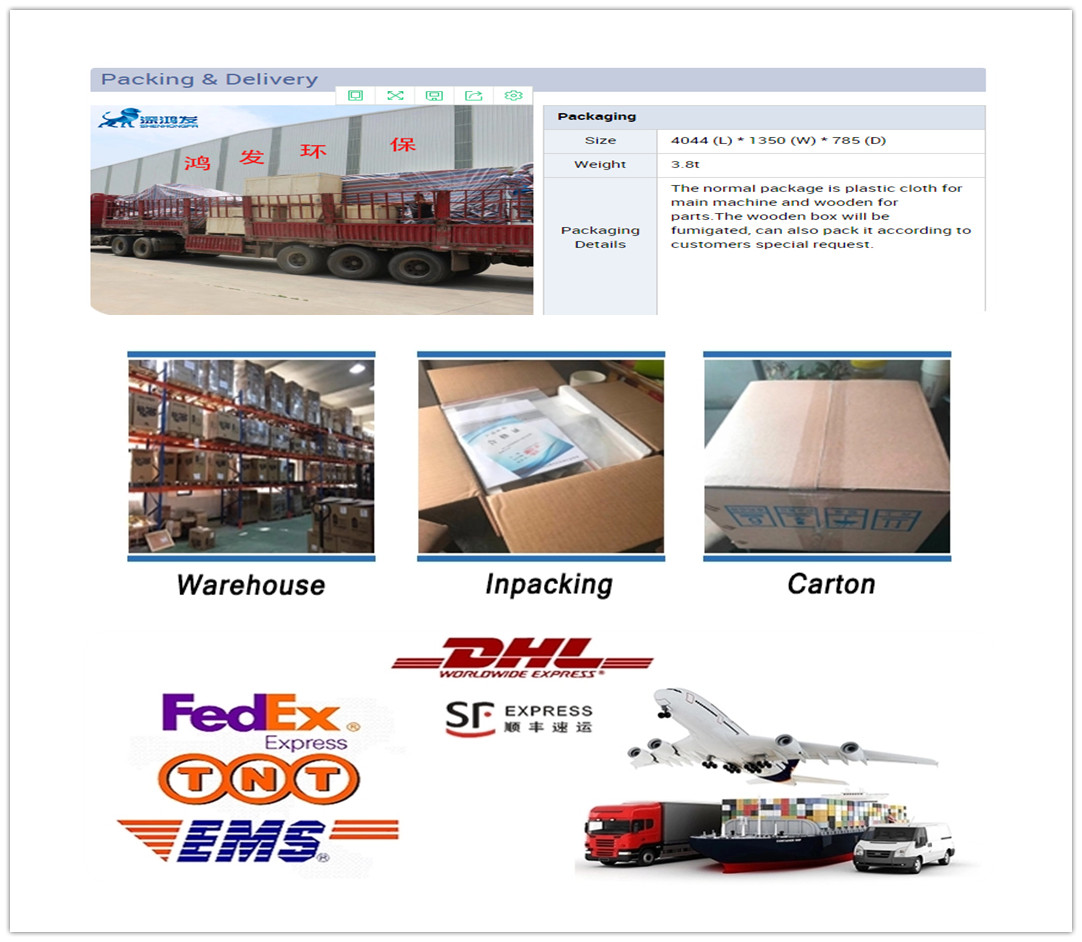

PACKING AND DELIVERY

Our Engineering Project

Advantages of Shenzhen HONGFA Filter Press:

1. Low filter cake moisture;

2. Unmanned operation and cost saving;

3. Resist high temperature and corrosion;

4. Good sealing effect can perfectly avoid leskage;

5. Energy saving high performance chamber filter press with long working life

Related Keywords